A four-in-one switch combination machine

A combination of switches and rack technology, applied in the direction of electric switches, electrical components, circuits, etc., can solve the problems of difficulty in using general manipulators, unsuitable for switch assembly, and increased production costs, and achieve implementability, simple structure, and improved The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Further description will be given below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

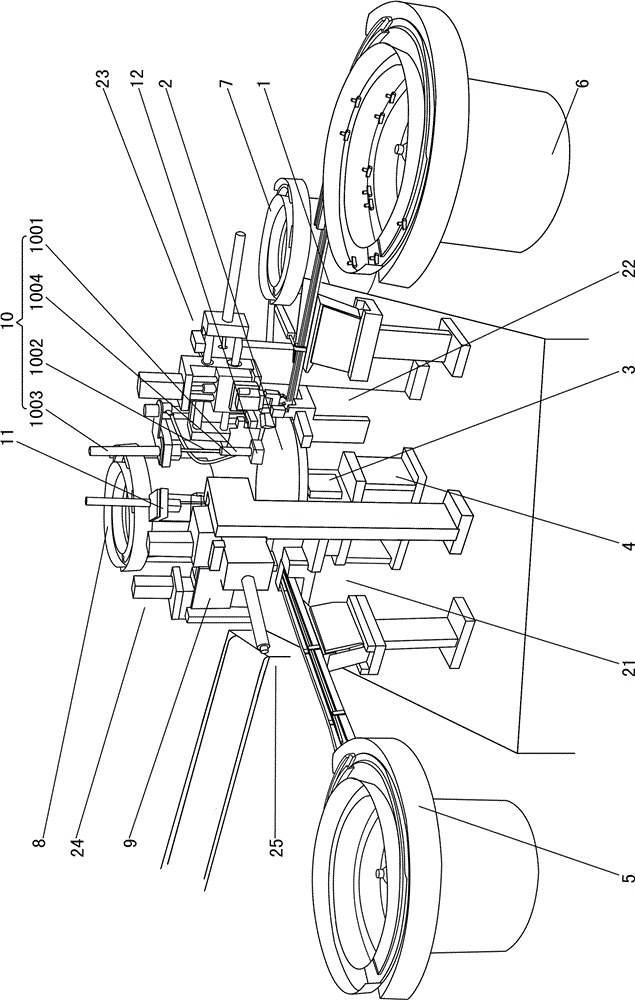

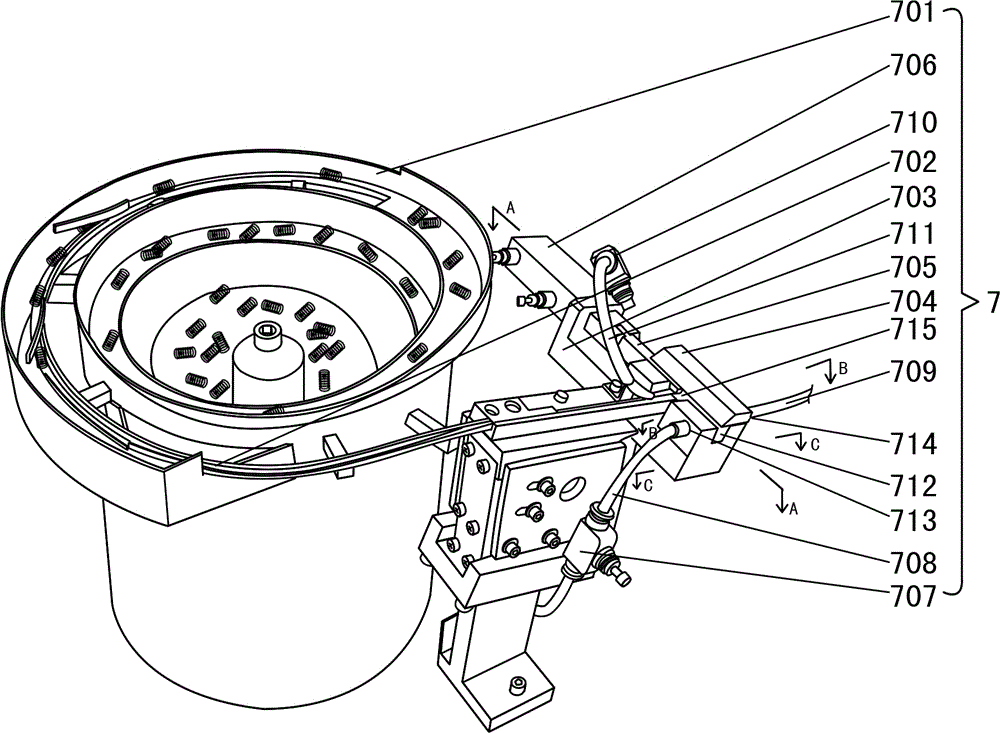

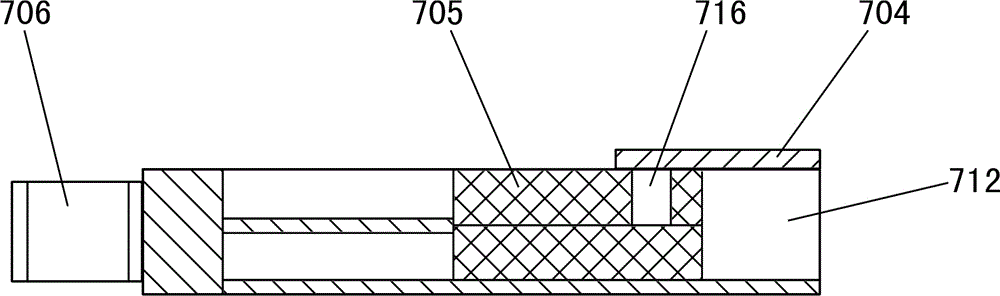

[0025] Such as figure 1 As shown, this four-in-one switch combination machine includes a frame 1, a turntable 2, a rotating shaft 3, a stepping motor 4, a casing feeding mechanism 5, a button feeding mechanism 6, an air-blowing spring conveying mechanism 7, and an air-blowing mechanism. Type plastic bolt conveying mechanism 8, finished product exit mechanism 9, spring pressing mechanism 10, plastic bolt pressing mechanism 11 and five switch card holders 12; stepping motor 4 is installed on the frame 1, and the turntable 2 is installed on the On the frame 1, the stepper motor 4 is connected to the rotating shaft 3; five switch decks 12 are installed on the turntable 2 at equal intervals along the circumference of the turntable 2; along the rotation direction of the turntable 2, the frame 1 is provided with shells Sending station 21,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap