Method for disassembling and assembling grounding wire through self-lockable grounding wire clamp

A technology of grounding wire clips and grounding wires, which is applied in the direction of clip connection, conductor connection, connection, conductive connection, etc., which can solve problems such as jamming, achieve easy removal, and improve labor efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

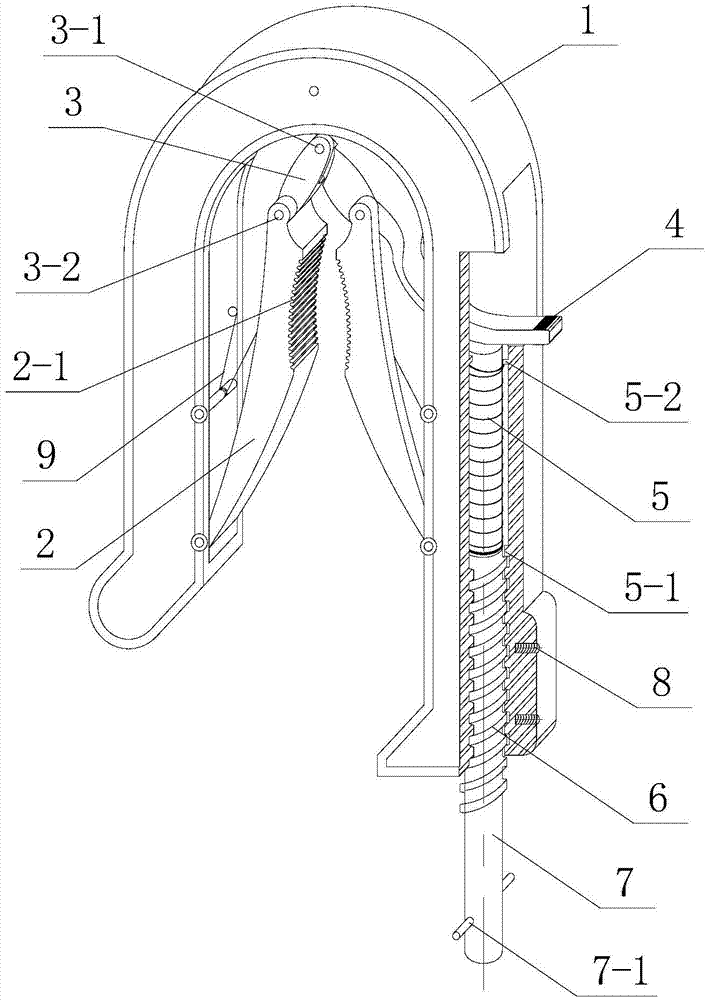

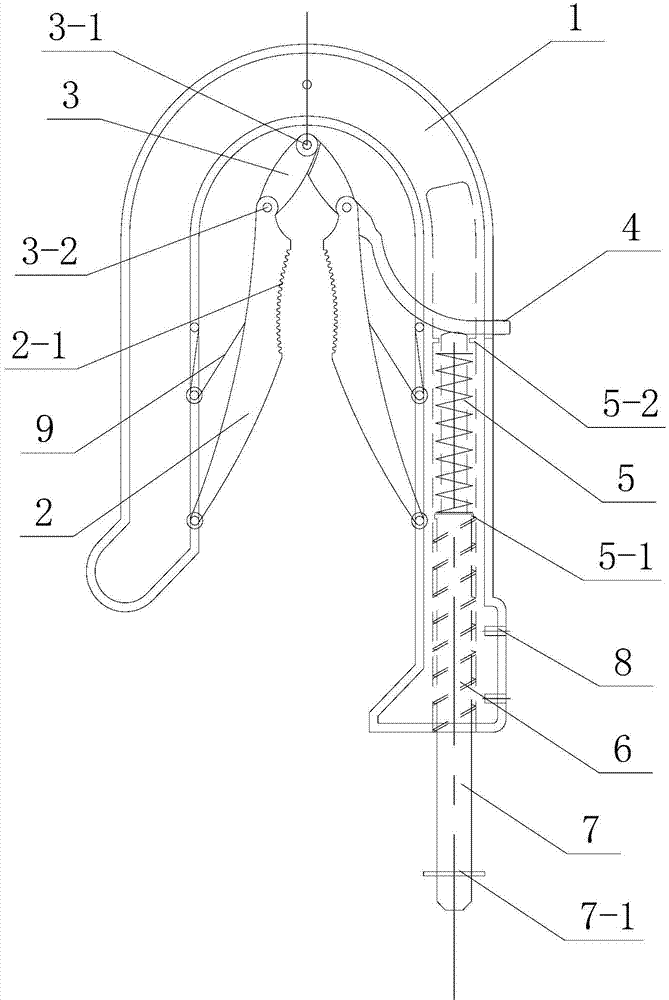

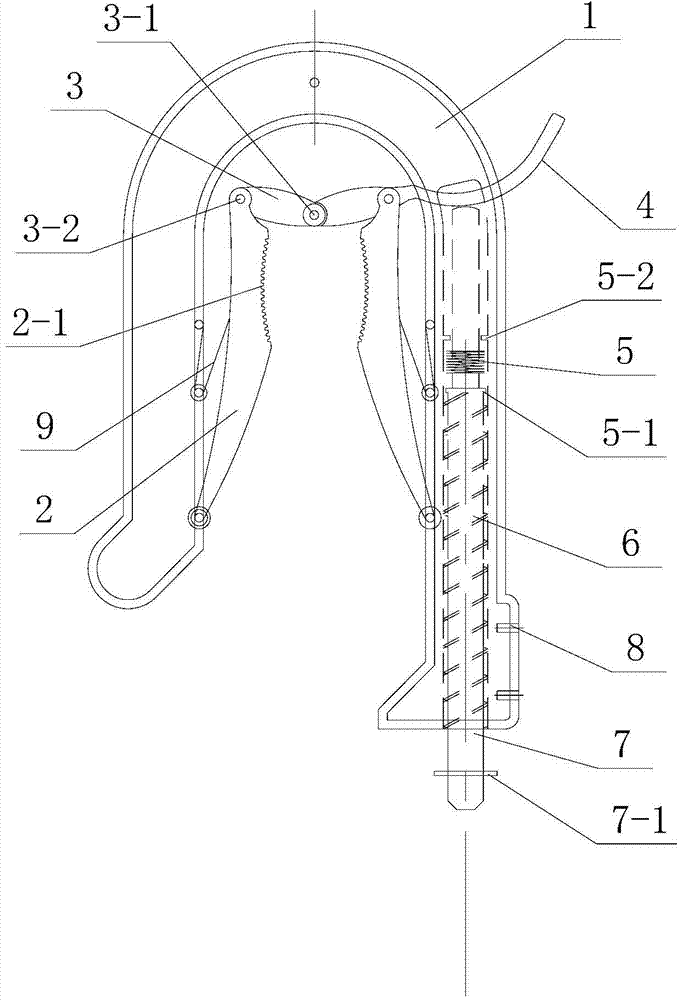

[0019] Specific implementation mode 1. Combination Figure 1 to Figure 3 Describe this embodiment, the method of using the self-locking grounding wire clamp to disassemble and install the grounding wire described in this embodiment, the self-locking grounding wire clamp includes a U-shaped clip body 1, two bow-shaped conductive clips 2, Movable locking piece 3, movable locking piece pressing handle 4, rotating compression spring 5, screw ejector rod 7, connection terminal 8 and clip compression spring 9;

[0020] The main body of the U-shaped clip body 1 is an inverted U-shaped structure, and the inner surface of the U-shaped clip body 1 has a U-shaped groove. The connecting side of the U-shaped clip body 1 and the insulating rod is a hollow structure. Quick thread 6, and the side of U-shaped clip body 1 has a rectangular through hole;

[0021] Two arcuate conductive clips 2 are relatively arranged in the U-shaped area of the U-shaped clip body 1, and the bottom ends of the...

specific Embodiment approach 2

[0029] Specific embodiment two, combine Figure 4 This embodiment is described. This embodiment is a further description of the self-locking ground wire clip described in the first embodiment. Shape groove 4-1 is corresponding with screw mandrel 7.

specific Embodiment approach 3

[0030] Specific embodiment 3. This embodiment and the further description of the self-locking grounding wire clamp described in specific embodiment 1 or 2, the inner sides of the two arcuate conductive clips 2 are provided with arc-shaped depressions, and the two arch-shaped The arc-shaped depressions on the conductive clip 2 are oppositely arranged.

[0031] The inner sides of the two bow-shaped conductive clips 2 described in this embodiment are provided with arc-shaped recesses 2-1 to tighten the ground wire when clamping the ground wire. The line slipped when the line appeared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com