Mechanical transmission roller wing lift force generation device

A generation device and mechanical transmission technology, applied in the direction of passing through cylindrical rotating parts, can solve the problems of low-speed flight performance, large wing area, and poor structural strength of fixed-wing aircraft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

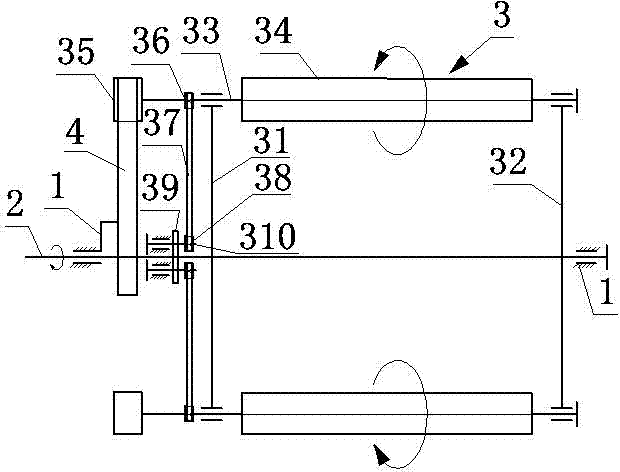

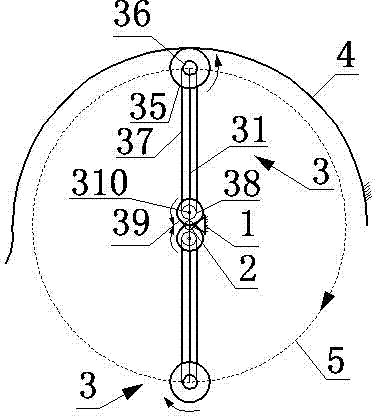

[0010] The present invention will now be described in detail with reference to the drawings: a mechanical drive drum wing lift generating device, comprising a frame 1, a main shaft 2, an arc guide 4 and two rotors 3 with the same structure symmetrically distributed around the main shaft 2; Each rotating wing 3 includes a left rotating arm 31, a right rotating arm 32, a roller shaft 33, a roller wing 34, a guide wheel 35, a driving synchronous wheel 36, a synchronous belt 37, a driven synchronous wheel 38, a gear 39 and a gear shaft 310. The drum wing 34 is a drum that can flexibly rotate around the axis of the drum shaft 33. The main shaft 2 is arranged horizontally, and the left and right ends of the main shaft 2 are respectively mounted on the frame 1 through bearings. The arc-shaped guide rail 4 is longitudinally installed above the horizontal plane of the main shaft 2 and directly above the guide wheel 35. The lower surface of the arc-shaped guide rail 4 is in contact with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com