Bottled food material conveying mechanism

A feeding mechanism and food technology, which is applied in the feeding field of labeling machines, can solve problems such as obstacles and fragile bottles, and achieve the effect of preventing bottles from breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below by means of specific embodiments:

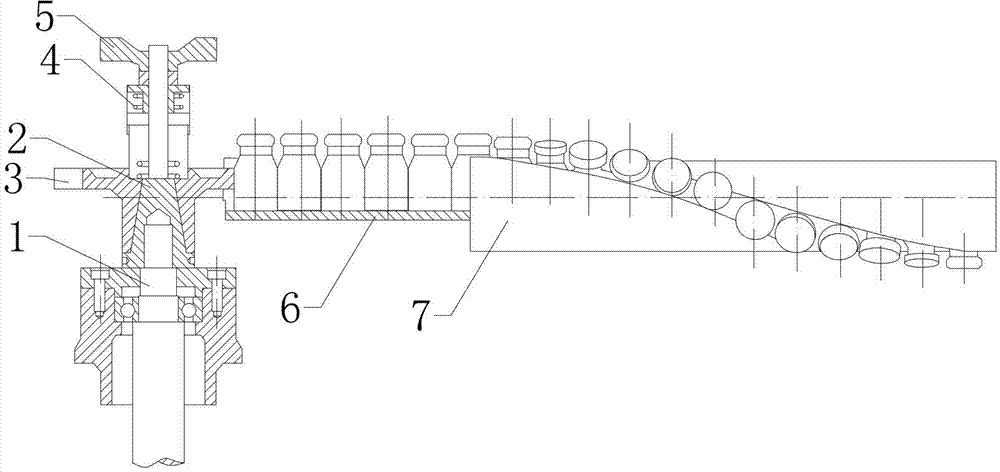

[0012] The reference signs in the drawings of the description include: transmission shaft 1, taper shaft 2, bottle pushing dial 3, compression spring 4, spring seat 5, bottled food guide rail 6, bottle turning guide rail 7.

[0013] The embodiment is basically as attached figure 1 As shown: the transmission shaft 1 is connected with the power output shaft (not shown in the figure), and one end of the transmission shaft 1 is screwed to the tapered shaft 2 to transmit power. In this embodiment, the outer circle of the bottle pushing dial 3 is evenly distributed with grooves, and the pushing part for pushing the bottle body is formed between the two groove walls. The middle part of the side surface of the bottle pushing dial 3 is provided with a boss. The axial direction of the bottle pushing dial 3 is provided with a taper hole, the taper of the taper hole is the same as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com