A plastic film suction cup

A plastic film and suction cup technology, which is used in thin material handling, object supply, pile separation, etc., can solve the problem that the suction nozzle cannot suck plastic film, cannot meet the requirements of automatic mechanical operation, and cannot withstand long-term high-frequency automatic mechanical operation. and other problems to achieve the effect of preventing wrinkling and air leakage, preventing vacuum leakage and preventing slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation method in the present invention will be further described below in conjunction with the accompanying drawings.

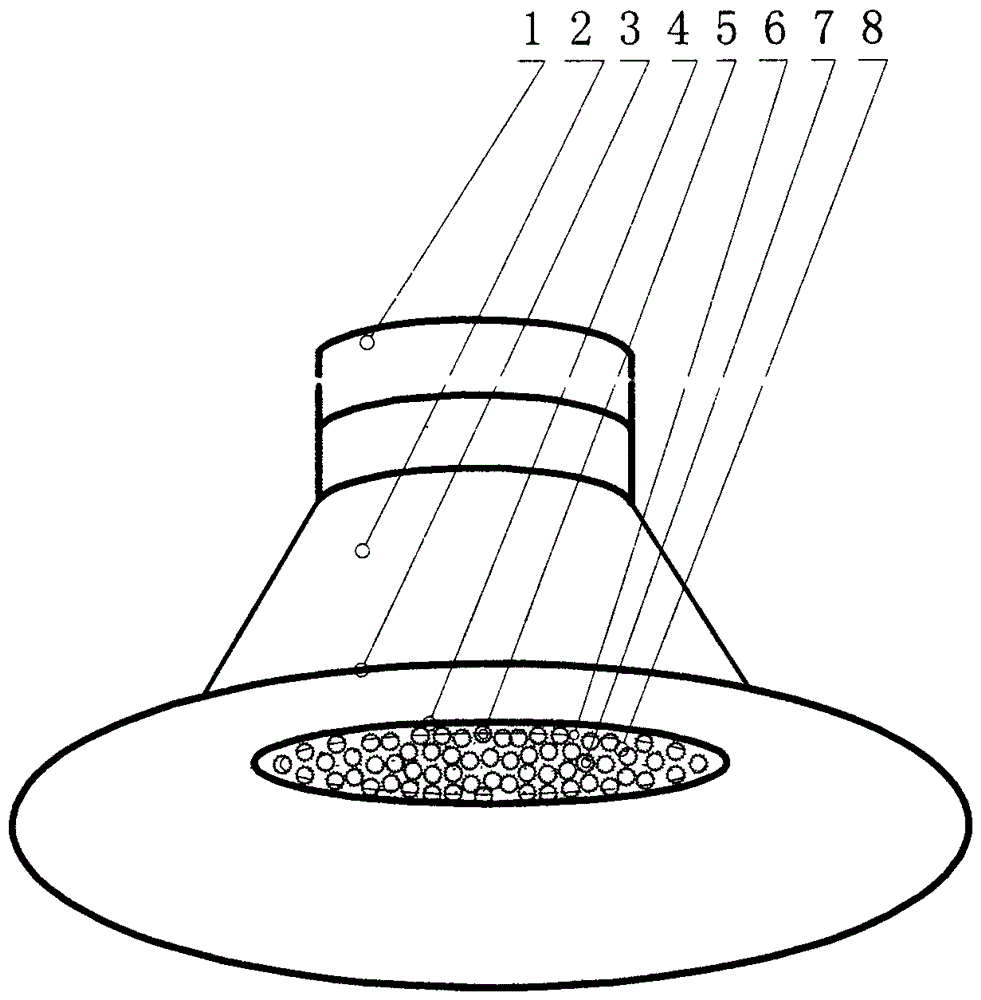

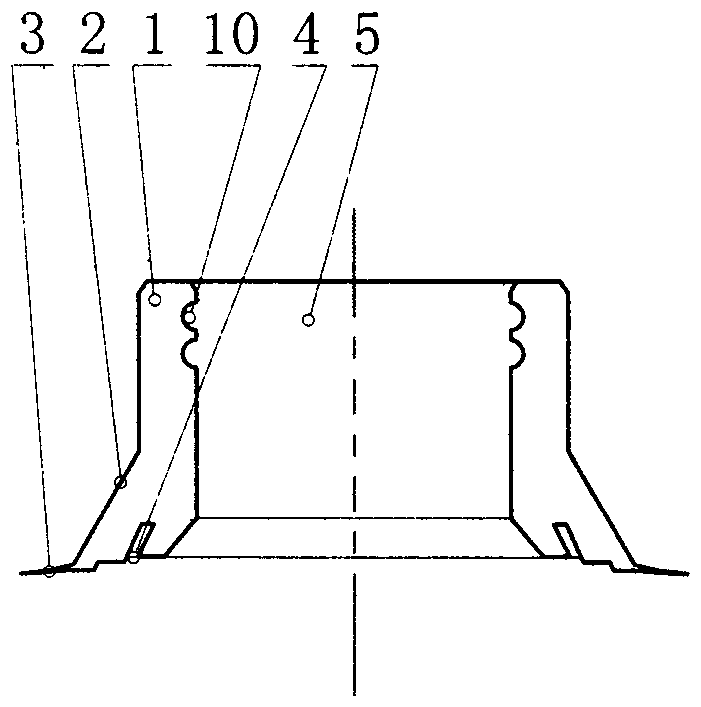

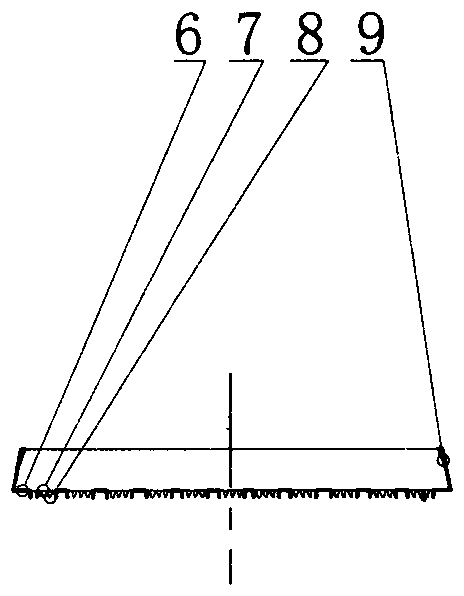

[0018] figure 1 , figure 2 , image 3 Among them, it includes suction head 1, suction neck 2, suction cup 3, orifice groove 4, suction hole 5, orifice plate 6, suction hole 7, burr 8, orifice buckle 9, cavity groove 10, etc.

[0019] The invention is a plastic film sucker, which includes a sucker mechanism and a stabbing plate mechanism.

[0020] The suction cup mechanism includes a suction head 1, a suction head 1, a suction neck 2, a suction cup 3, an orifice groove 4, a suction hole 5, and a chamber groove 10; the suction neck 2 is arranged under the suction head 1, and the suction cup 3 is arranged on The lower end of the neck 2, the orifice groove 4 is arranged in the lower end of the inner cavity of the suction neck 2, the suction head 1, the suction neck 2, and the suction cup 3 are integrated; the suction hole 5 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com