An experimental simulation mechanism for multiphase flow with water entry and aeration

A multiphase flow, experimental simulation technology, applied in fluid dynamics tests, testing of machine/structural components, measuring devices, etc., can solve the problem of lack of experimental methods, lack of sufficient understanding, affecting the trajectory of the model and the formation of multiphase flow. and other issues to reduce interference and ensure effectiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

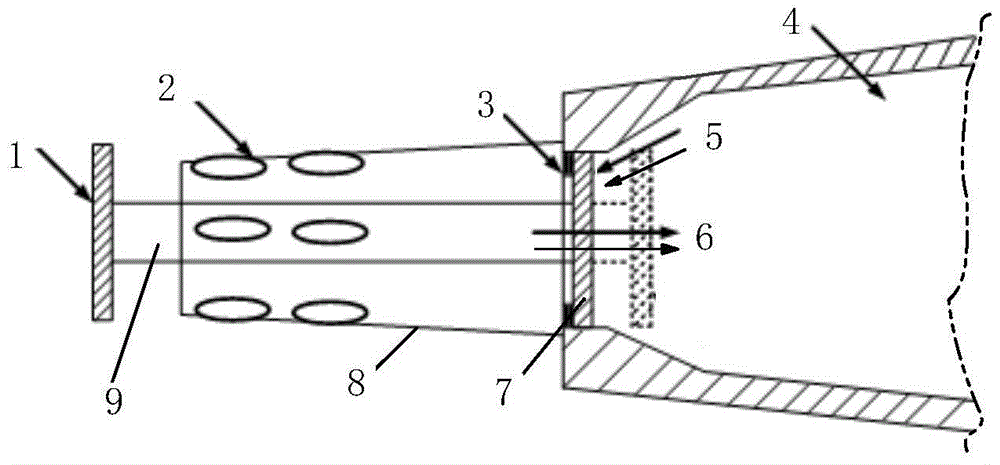

[0014] combine figure 1 , the present invention comprises a conical air collection chamber 4, an annular sealing ring 3 installed at the end of the conical air collecting chamber 4, an airtight seal installed at the end of the conical air collecting chamber 4 and positioned inside the annular sealing ring 3 The cover plate 7, the piston rod 9 fixedly connected to the center of the airtight cover plate 7, and the cavitator 1 connected to the other end of the piston rod 9, and a hollow cylindrical platform 8 is also provided outside the end of the conical air collection chamber 4 , the hollow cylindrical surface 8 is provided with at least six ventilation holes 2 in the circumferential direction, and the intervals between the ventilation holes are equal, and the piston rod 9 is located inside the hollow cylindrical surface 8 .

[0015]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com