Rotary disc reactor

A reactor and rotary disk technology, applied in the field of reactors, can solve the problems of difficulty in ensuring the heat transfer effect between solid-solid phases and the depth of the pyrolysis reaction, so as to enhance the degree of mixing and the effect of interphase heat transfer, and enhance the mixing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

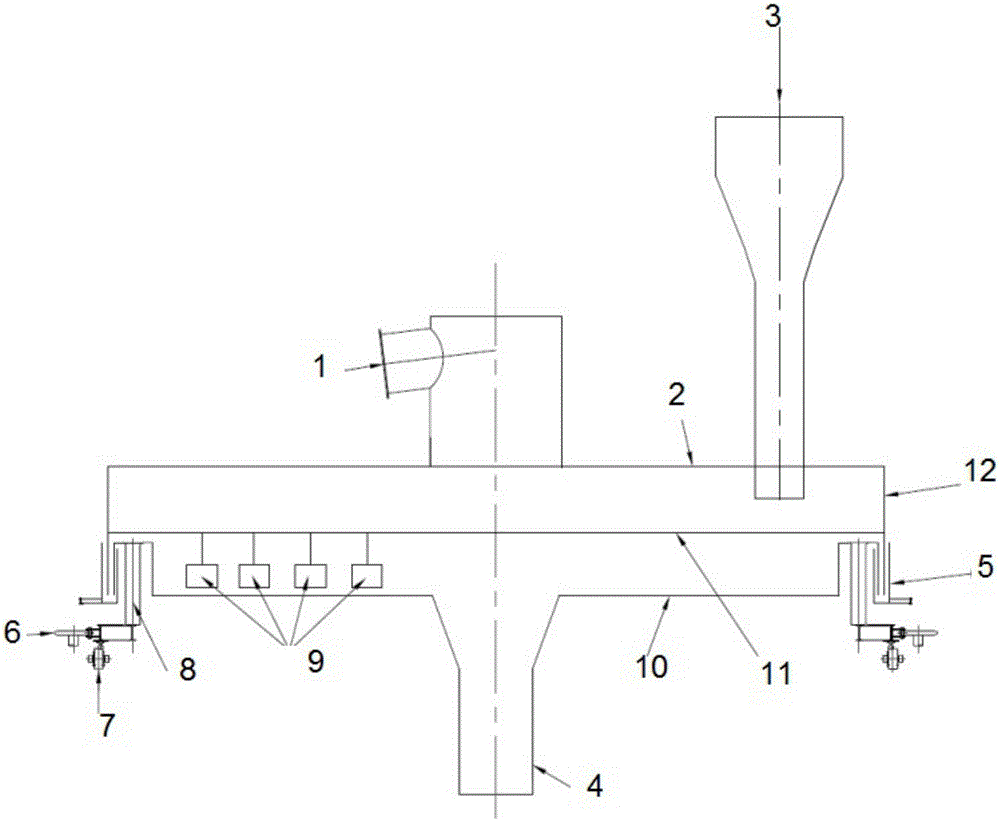

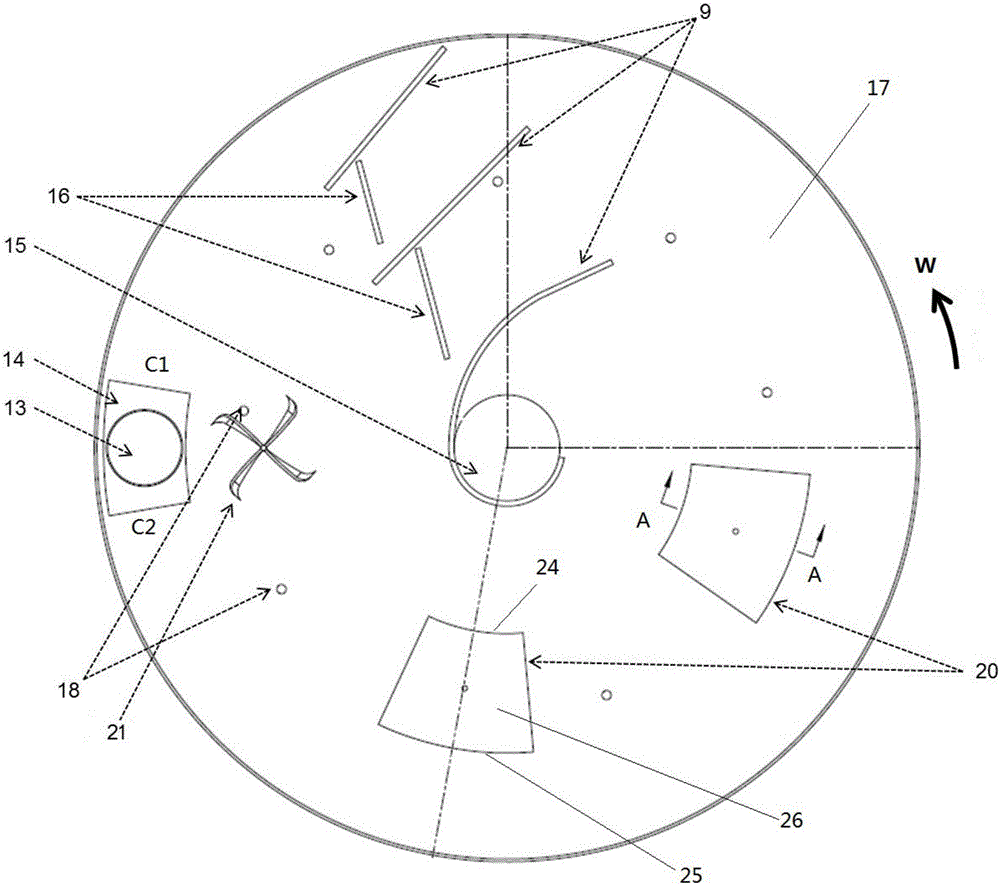

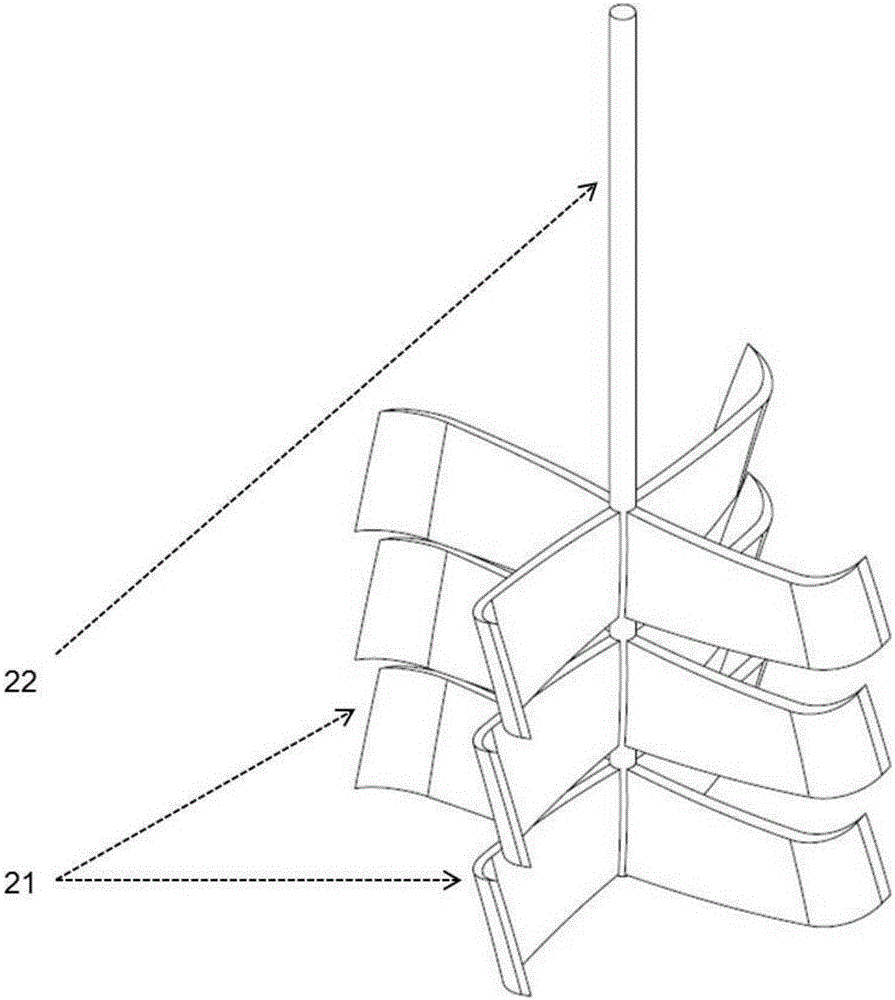

[0075]The raw coal processing capacity of the rotary disk reactor is 500,000 tons per year, and the pyrolysis semi-coke is used as the heat carrier. The temperature of raw coal after drying is 150-200°C, the temperature of heat carrier is 750-800°C, the pyrolysis reaction temperature is 550-650°C, the mass ratio of heat carrier and dry coal is 4:1, and the pyrolysis reaction time is about 30min. The outer diameter of the tray of the rotary disk reactor is 27.5m, the diameter of the discharge pipe is 3.0m, and there are 4 levels of material guide plates. The width of each level from the outside to the inside is about 1.8m, 2.1m, 2.8m and 5.4m. The thickness is 0.4m. The groups of mixing mechanisms set on the guide plates at all levels are 2, 1, 1, and 1 respectively, and each group of mixing mechanisms contains 3 layers of four-petal plow-shaped rotating blades (height 0.1m, layer spacing 0.02m) .

[0076] The pyrolysis test results show that the semi-coke yield, tar yield a...

Embodiment 2

[0078] Raw coal and liquefaction residue are co-pyrolyzed. The total processing capacity of the rotary disk reactor is 500,000 tons per year (the blending amount of liquefaction residue is 20%), and pyrolysis semi-coke is used as the heat carrier. The temperature of raw coal after drying is 100-130°C, the feed temperature of liquefaction residue is 20°C, the temperature of heat carrier is 750-800°C, the temperature of pyrolysis reaction is 550-650°C, and the mass ratio of heat carrier and pyrolysis raw material is 4:1, the pyrolysis reaction time is about 25min. The outer diameter of the tray of the rotary disk reactor is 25.8m, the diameter of the discharge pipe is 3.0m, and there are 4 levels of material guide plates. The width of each level from the outside to the inside is about 1.7m, 2.0m, 2.6m and 5.1m. The thickness is 0.375m. There are 3, 2, 1, and 1 groups of mixing mechanisms at each level (the liquefied residue is viscous and has a small particle size, and the requ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com