Wireless detection system and method for measuring state parameters in core simulation device

A state parameter and detection system technology, applied to the record carrier used by the machine, the instrument, the induction record carrier, etc., can solve the problem of not being able to directly and real-time measure the design parameters such as the core temperature and the inability to give a spherical analog fuel element movement Trajectory and other issues, to achieve the effect of accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and implementation examples. The following examples are only used as exemplary descriptions of the implementation of the present invention, and do not limit the scope of the present invention in any way.

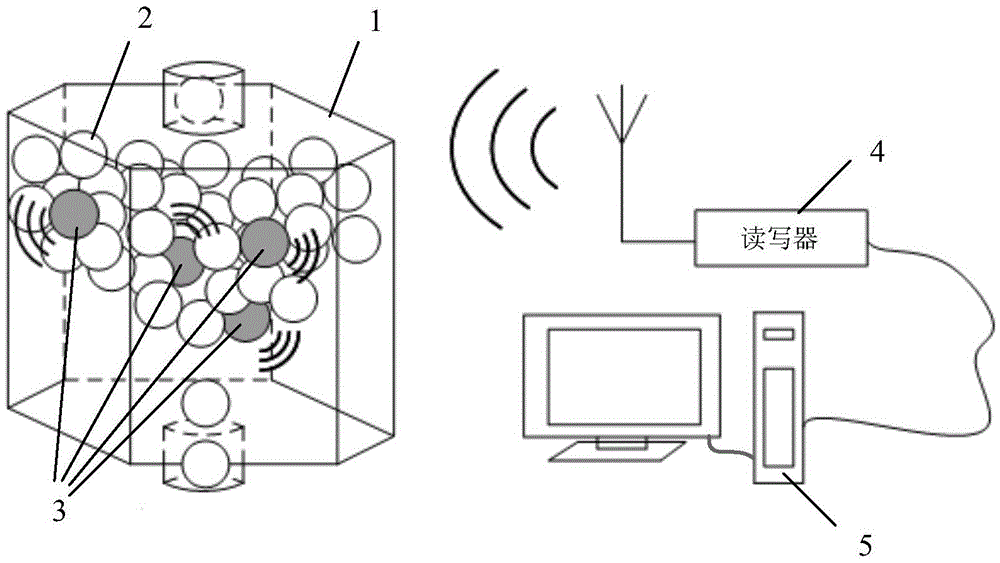

[0030] figure 1 It shows the wireless detection system for measuring the state parameters in the molten salt reactor core simulation device of the present invention, wherein the core simulation device here includes a core vessel 1 and several core vessels placed in the core vessel 1 as stack The spherical shape of the core simulates the fuel element 2 .

[0031] exist figure 1 In the shown embodiment, the wireless detection system includes a reader 4 and a host computer 5 arranged outside the core vessel 1 and connected to each other, and four spherical detection devices 3 placed in the core vessel 1 .

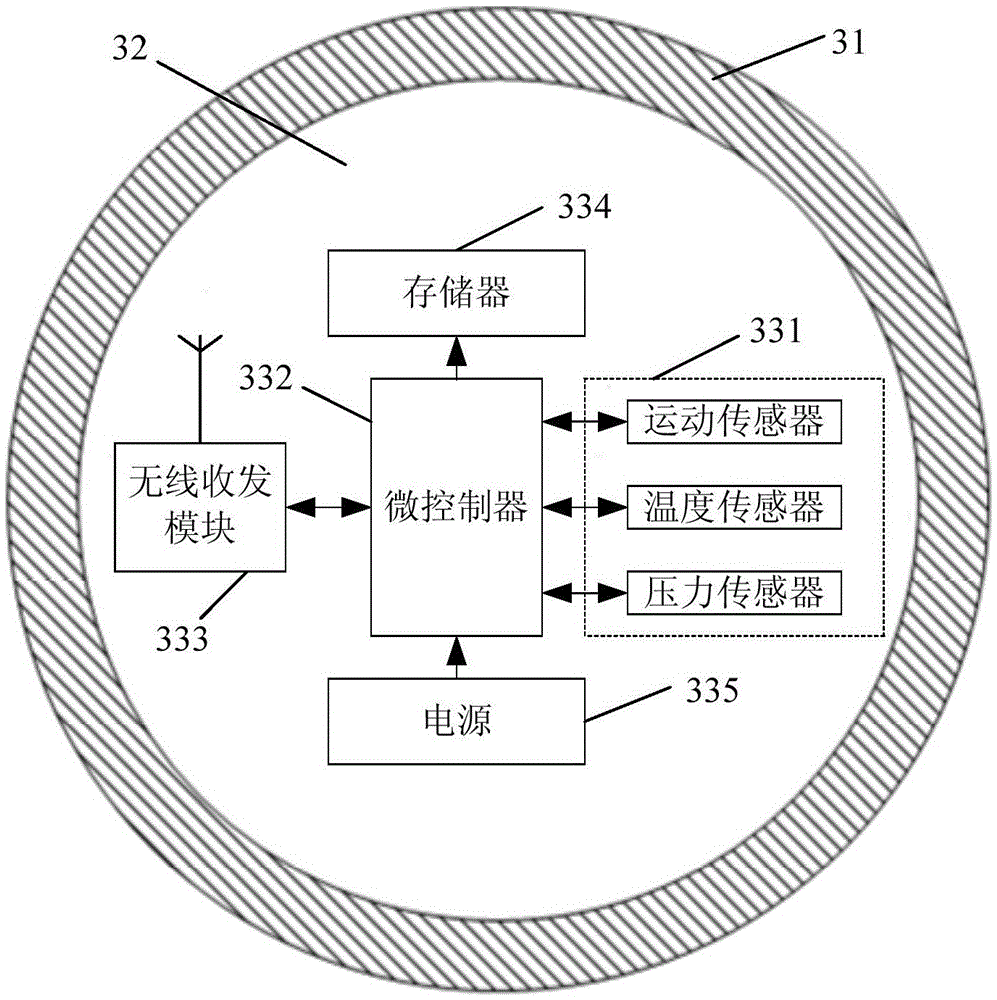

[0032] figure 2 The structure of the spherical detection devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com