Gear hobbing method for technological parameter self-learning optimization in machining process

A technology for process parameter optimization and process parameter application in the field of gear processing, which can solve the problems of poor generalization ability, inability to learn optimization, unstable output of a single neural network, etc., to overcome the slow convergence speed and improve the effect of gear hobbing processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

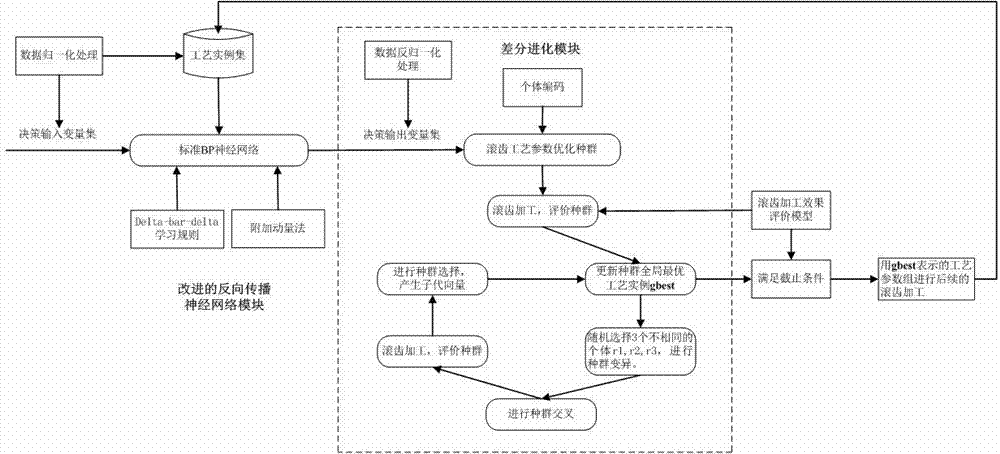

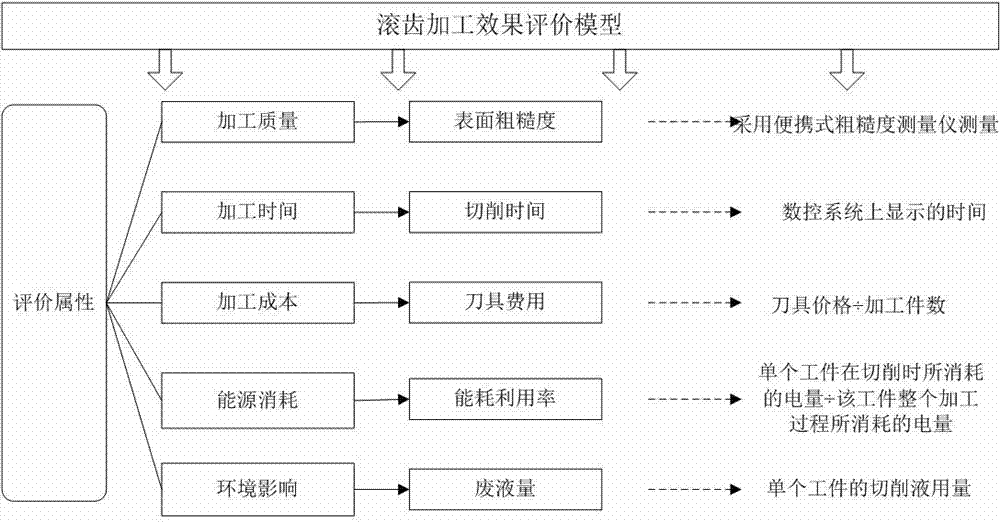

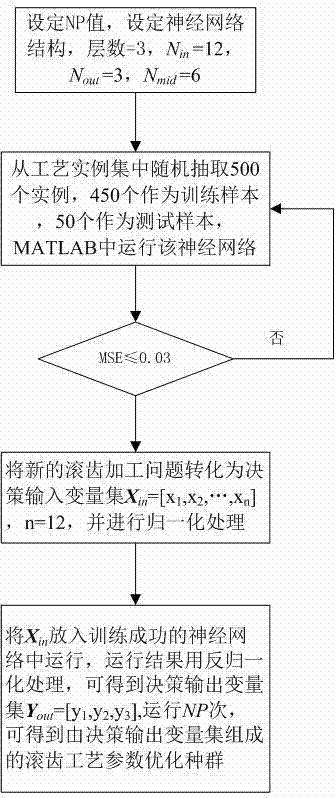

[0023] The train of thought of the present invention is: utilize the improved backpropagation neural network algorithm to transform the decision-making input variable set into the decision-making output variable set, and have the hobbing process parameter optimization population that the differential evolution algorithm needs to form the decision-making output variable set; Utilize this population Carry out separate processing, and with the support of the hobbing effect evaluation model, the differential evolution algorithm can continuously optimize the process parameters in the hobbing process. After meeting the cut-off conditions, the global optimal process instance of the population is obtained, that is, the comprehensive The process instance with the best evaluation value is used for subsequent hobbing and stored in the process instance set. When there is a new problem of gear hobbing, repeat the above steps to complete the automatic hobbing process parameters in the process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com