Display panel motherboard and preparation method thereof

A technology for display panels and motherboards, which is used in the identification of devices, instruments, semiconductor devices, etc., can solve problems such as time-consuming and affect the production capacity of the production line, and achieve the effect of improving the production capacity of the production line and optimizing the design space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The principle of the present invention is to use the positioning mark on the array substrate and the specific number of transition sub-pixels in the non-display area on the side of the display area on the color filter substrate to realize the marking of the display panel.

[0039] When identifying the display panel, the display panel to be identified can be placed under a high-power microscope, and first determined by observing the specific number of transition sub-pixels in the non-display area on the side of the display area on the color filter substrate The process area to which the display panel belongs, and then the specific position of the display panel in the process area is determined by observing the positioning mark on the array substrate, and then the specific position of the display panel in the display panel mother board can be determined.

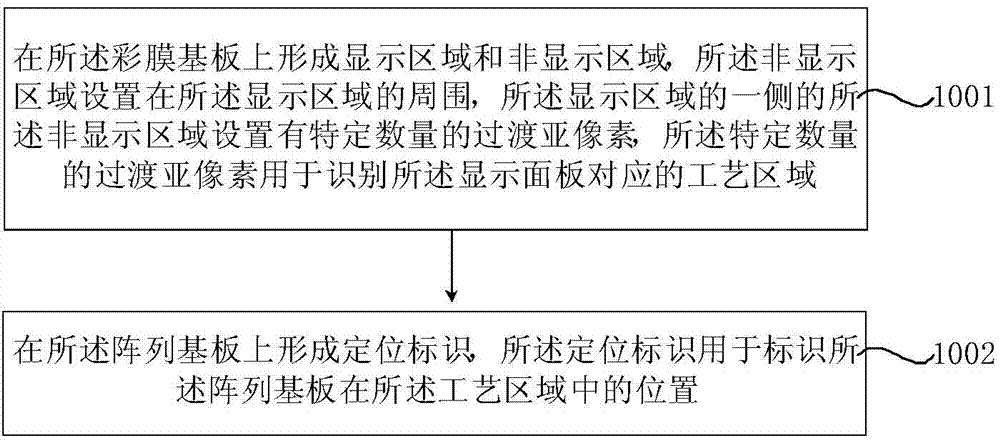

[0040] figure 1 It is a flow chart of a method for manufacturing a display panel motherboard provided by Embodiment 1...

Embodiment 2

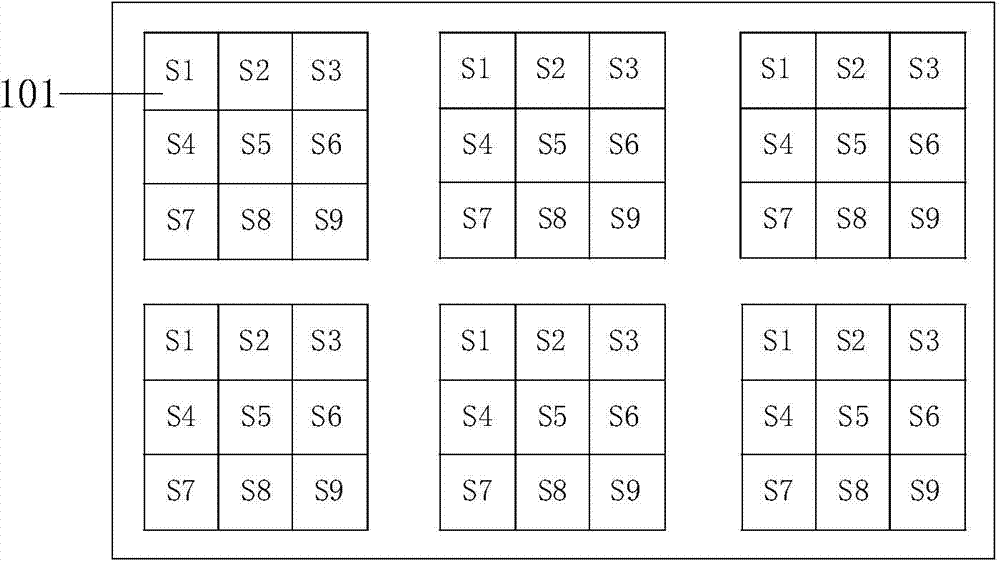

[0055] This embodiment provides a motherboard for a display panel, which includes a plurality of process areas, the process areas include a plurality of display panels, and the display panels include a color filter substrate and an array substrate that are oppositely arranged. The color filter substrate includes a display area and a non-display area, the non-display area is arranged around the display area, and the non-display area on one side of the display area is provided with a specific number of transition sub-pixels, so The specific number of transition sub-pixels is used to identify the corresponding process area of the display panel. The array substrate includes a positioning mark, and the positioning mark is used to mark the position of the array substrate in the process area.

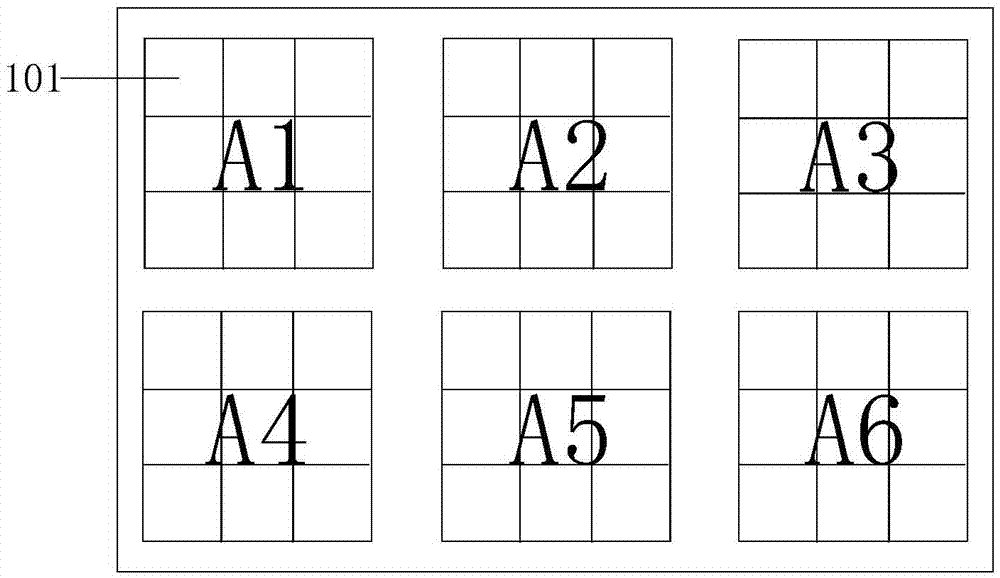

[0056] see figure 2 and image 3 , the display panel includes six process areas 101, namely A1, A2, A3, A4, A5 and A6, and each process area 101 contains nine display panels, namely S1, S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com