Shipping work planning system, shipping work planning method, and shipping work method

A technology of operation planning and operation, which is applied in the direction of calculation, data processing applications, instruments, etc., and can solve problems such as unusable operation planning, larger and larger ships, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

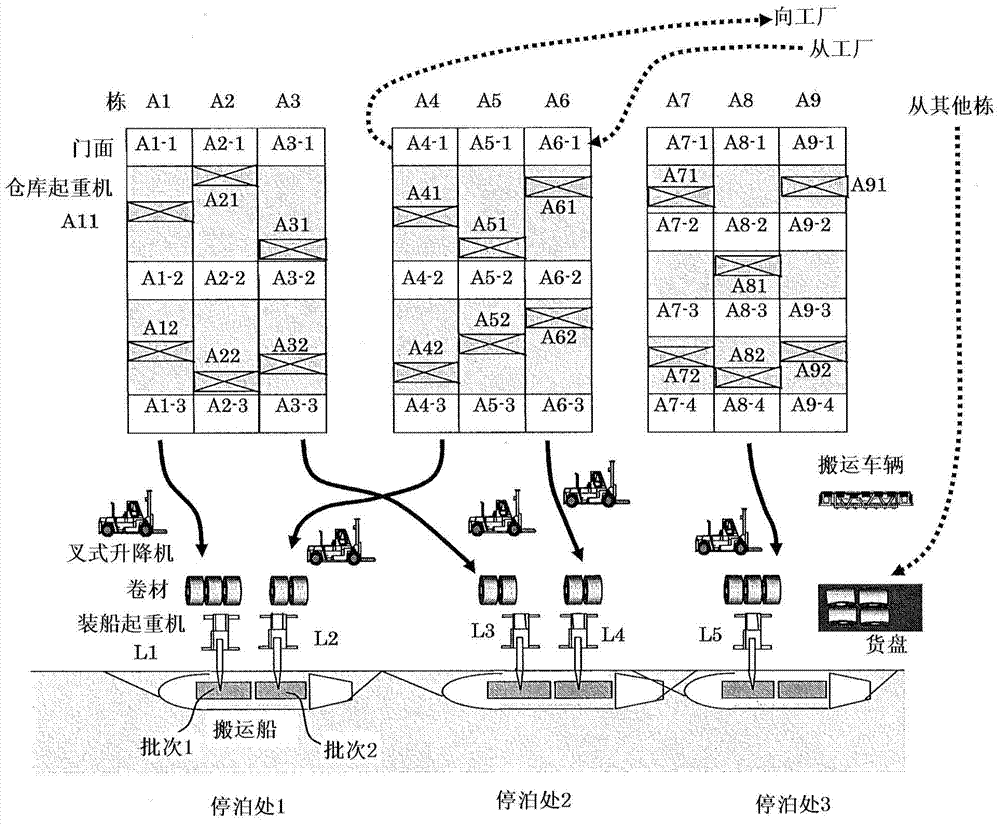

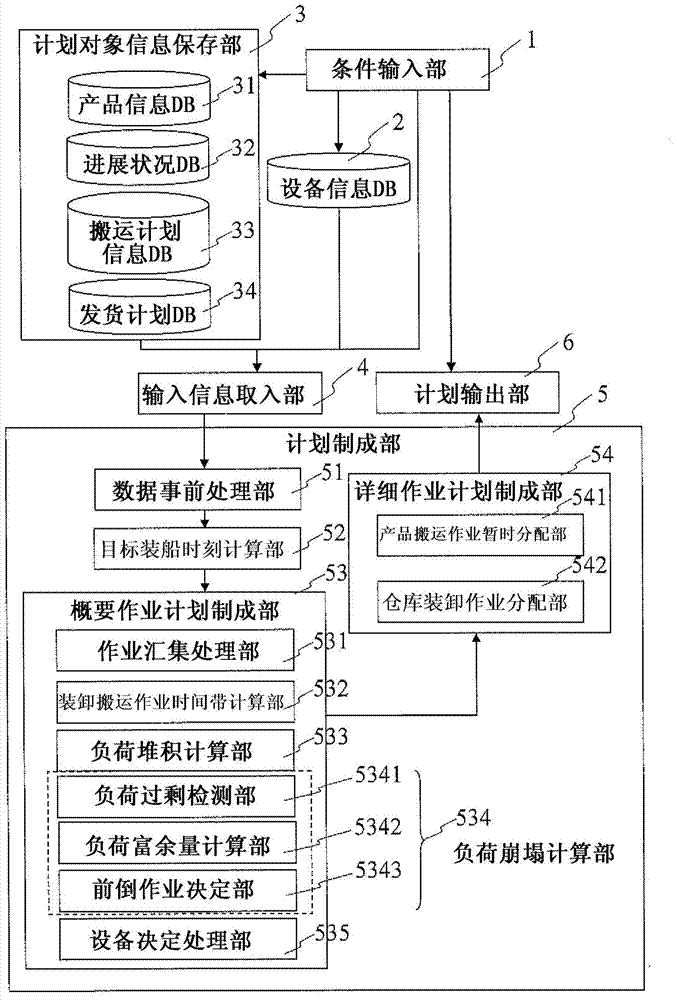

[0069] In this embodiment, the creation of a shipping work plan for shipping near a shipping dock from a shipping product storage place such as a warehouse or a product yard will be described. First, the configuration of the delivery facility that is the target of the delivery work plan preparation system according to Embodiment 1 to create the work plan will be described.

[0070] figure 1 It is a schematic diagram showing an example of the configuration of a shipping facility that is the target of the shipping work plan preparation system according to Embodiment 1 to create a work plan. Shipping equipment consists of multiple warehouse buildings, multiple product placement locations, multiple loading berths, multiple loading and unloading equipment, and multiple handling equipment. Here, the loading and unloading equipment refers to a loading crane or a warehouse crane, and the handling equipment refers to a fork lift or a handling vehicle.

[0071] exist figure 1 In the ...

Embodiment approach 2

[0225] In this embodiment, the creation of a shipping work plan for separate shipping operations from a shipping product storage place such as a warehouse or a product yard to a shipping dock will be described. Figure 17 It is a schematic diagram showing an example of the configuration of a shipping facility that is the target of the shipping work plan preparation system according to Embodiment 2 to create a work plan.

[0226] Since the transportation distance from the warehouse to the dock becomes longer, a transportation vehicle is used instead of a forklift. Handling vehicles are capable of handling more product at one time than fork lifts. Furthermore, the transport vehicle that transports the shipped products to the dock has a structure in which the traction unit and the trolley unit are not separated. Hereinafter, this embodiment will be described focusing on differences from Embodiment 1. FIG.

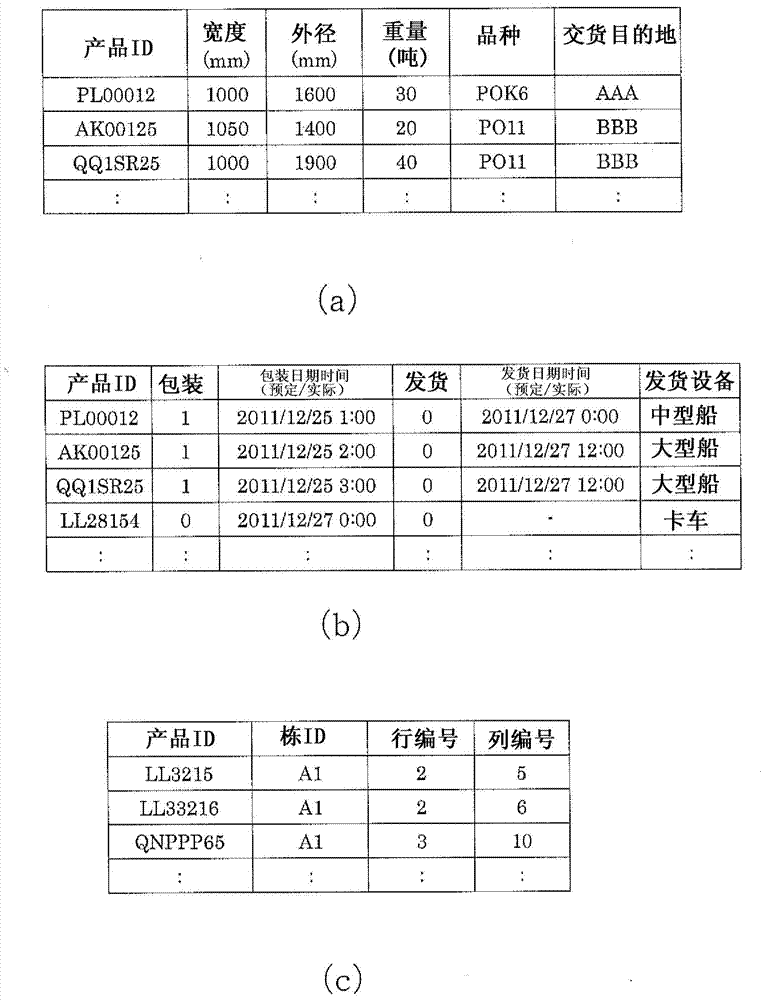

[0227] [Shipment plan / actual performance information]

[0228] In Em...

Embodiment

[0249] The shipment work plan preparation corresponding to Embodiment 1 was performed using the shipment work plan preparation system of this invention. As a result, the shipping work plan was prepared for the 24-hour operation of the shipping equipment of the six shipping cranes, and the planning was completed in about one minute using this shipping work planning system. Compared with the case of manual planning (approximately 1 hour), the planning creation time is significantly shortened. Furthermore, in the prepared shipping work plan itself, compared with the case where the plan is prepared manually, the waiting time of the loading crane becomes 30% or less, and an effective plan can be created.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com