Roof hanging steel bar installation tool assembly and climbing-free hanging steel bar installation method using same

A technology for installing tools and suspending bars, applied in manufacturing tools, hand-held tools, metal processing equipment, etc., can solve the problems of labor-intensive, low work efficiency, and personal safety of personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

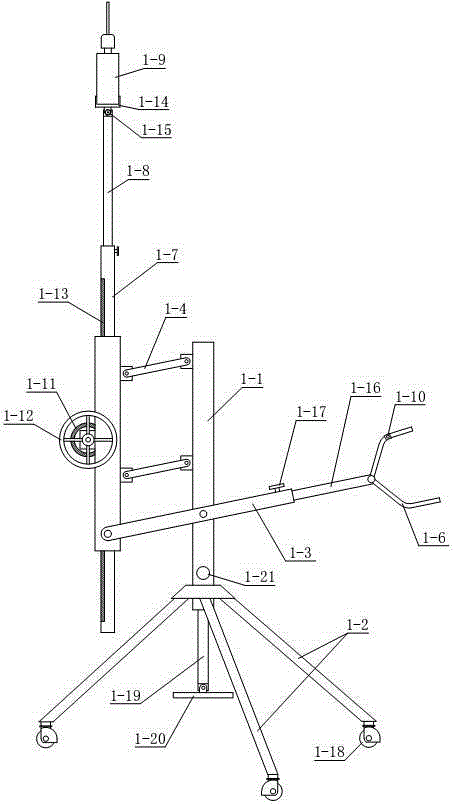

[0029] Referring to the accompanying drawings, the roof hanger installation tool assembly includes a drilling device and an installation device.

[0030] Such as figure 1 As shown, the drilling device includes a column 1-1, the bottom of the column 1-1 is provided with a support seat 1-2, the column 1-1 is hinged with a swing arm 1-3, and one side of the column 1-1 is connected The rod 1-4 is connected with a chute 1-5 which is arranged vertically and can move up and down. The middle part of the swing arm 1-3 is hinged on the column 1-1, and one end of the swing arm 1-3 is hinged on the chute 1. The bottom and the other end of -5 are equipped with a handle 1-6; vertically sliding on the chute 1-5, a telescopic arm 1-7 driven by a handwheel drive mechanism is installed, and the top of the telescopic arm 1-7 is connected with an extension rod 1 -8, the top end of the extension rod 1-8 is equipped with a percussion drill 1-9, and the power switch 1-10 of the percussion drill 1-9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com