Visual automatic oiling device and method for high-altitude steel wire cable

An oiling device and cable technology, which is applied to the surface coating device and coating, etc., can solve the problems of steel cable weather station safety, integrity threat, high manpower and material resources, high safety risk, etc., to achieve The effect of eliminating the risk of personnel working at heights, low price, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

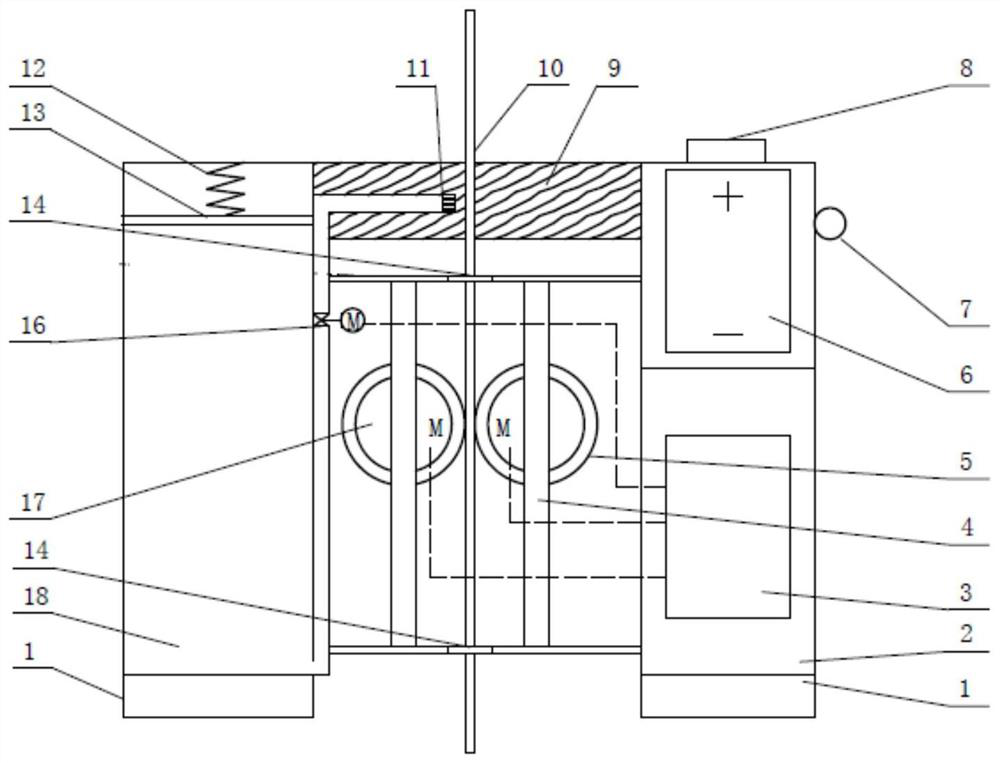

[0030] Such as figure 1 As shown, the present invention provides a visual automatic oiling device for high-altitude steel wire cables, including an electric drive and control module, and an oiling implementation module; the electric drive and control module controls the oiling implementation module to implement oiling on the steel wire rope 10 .

[0031] The electric drive and control module includes a remote controller 3, a cylindrical power wheel 5, and a power wheel motor 17. The both sides of steel wire rope 10 are respectively provided with a cylindrical power wheel 5; The interior of each cylindrical power wheel 5 is all provided with a power wheel motor 17, drives cylindrical power wheel 5 to rotate, makes the visual high-altitude wire cable automatic oiling device can be along Rolling and climbing on wire cables. The remote controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com