Flame spraying protection method and protection fixture for aircraft slide rail parts

A technology for protecting fixtures and flame spraying, applied in coating, fusion spraying, metal material coating technology and other directions, can solve the problems of simple structure, inconvenient use, poor protection ability, etc., to achieve good versatility, convenient use, good The effect of spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

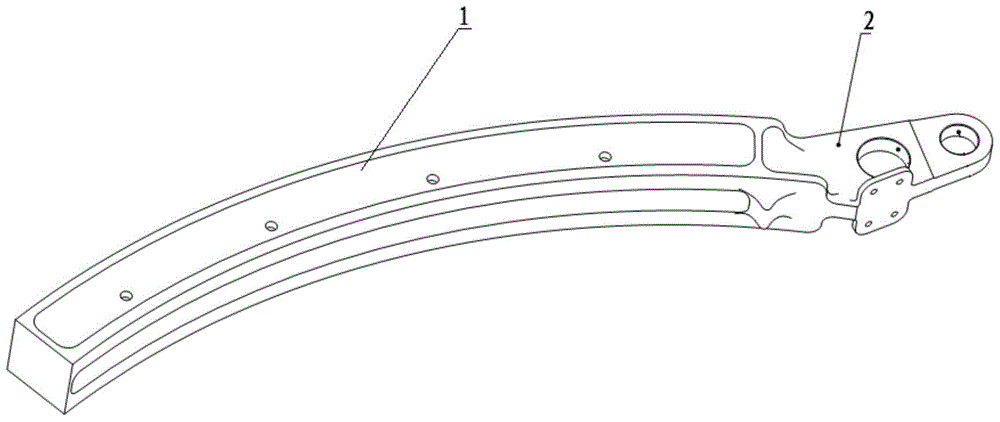

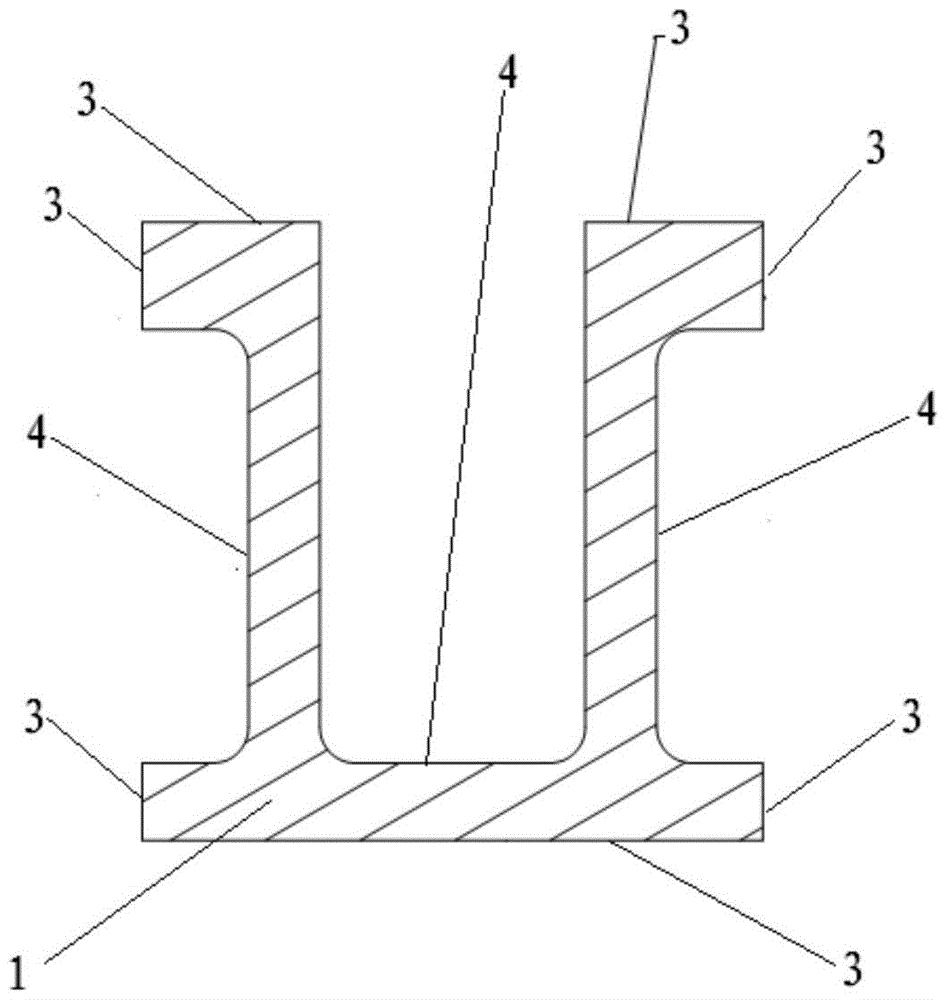

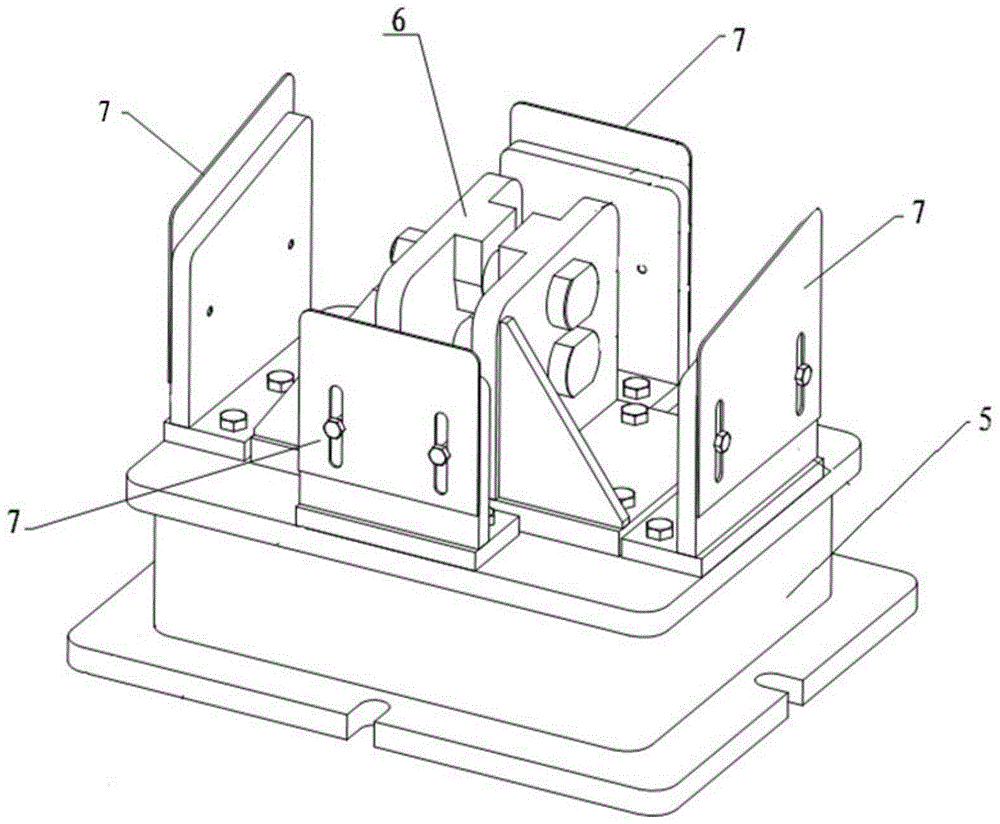

[0017] Referring to the attached drawings, aircraft slide rails such as figure 1 As shown, the end of the slide rail part 1 is the part joint 2, and the part joint 2 is provided with a positioning surface and a connecting hole for assembly. The body of the slide rail part 1 is a polyhedron structure with grooves 4 on three sides, such as figure 2 As shown, when flame spraying, the sprayed surface 3 needs to be exposed, and the part joints 2 and grooves 4 need to be protected. To this end, the present application provides a protective jig, the protective jig is composed of image 3 The fixture base shown and Figure 4 The slide rail protection body shown is composed of the described fixture base body containing a fixture base 5 on which a positioning corner seat 6 of the part joint is fixed. The positioning corner seat is composed of left and right parts, and the positioning corner seat is fixed through a U-shaped connecting hole On the fixture base, the distance between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com