Compressor exhaust structure and compressor with the exhaust structure

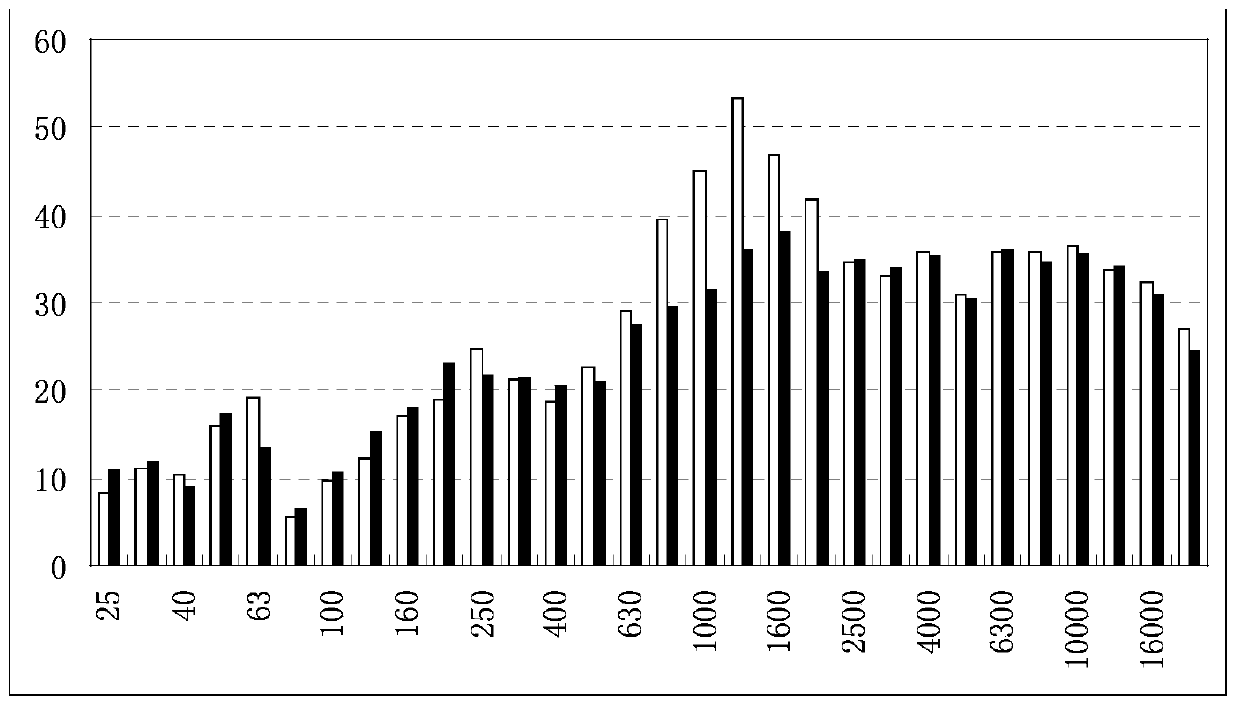

A compressor exhaust and exhaust port technology, applied in the field of compressors, can solve the problems of sharp ear sound, high frequency components of aerodynamic noise, poor sound quality, etc., and achieve the effect of improving sound quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the following embodiments and features in the embodiments can be combined with each other.

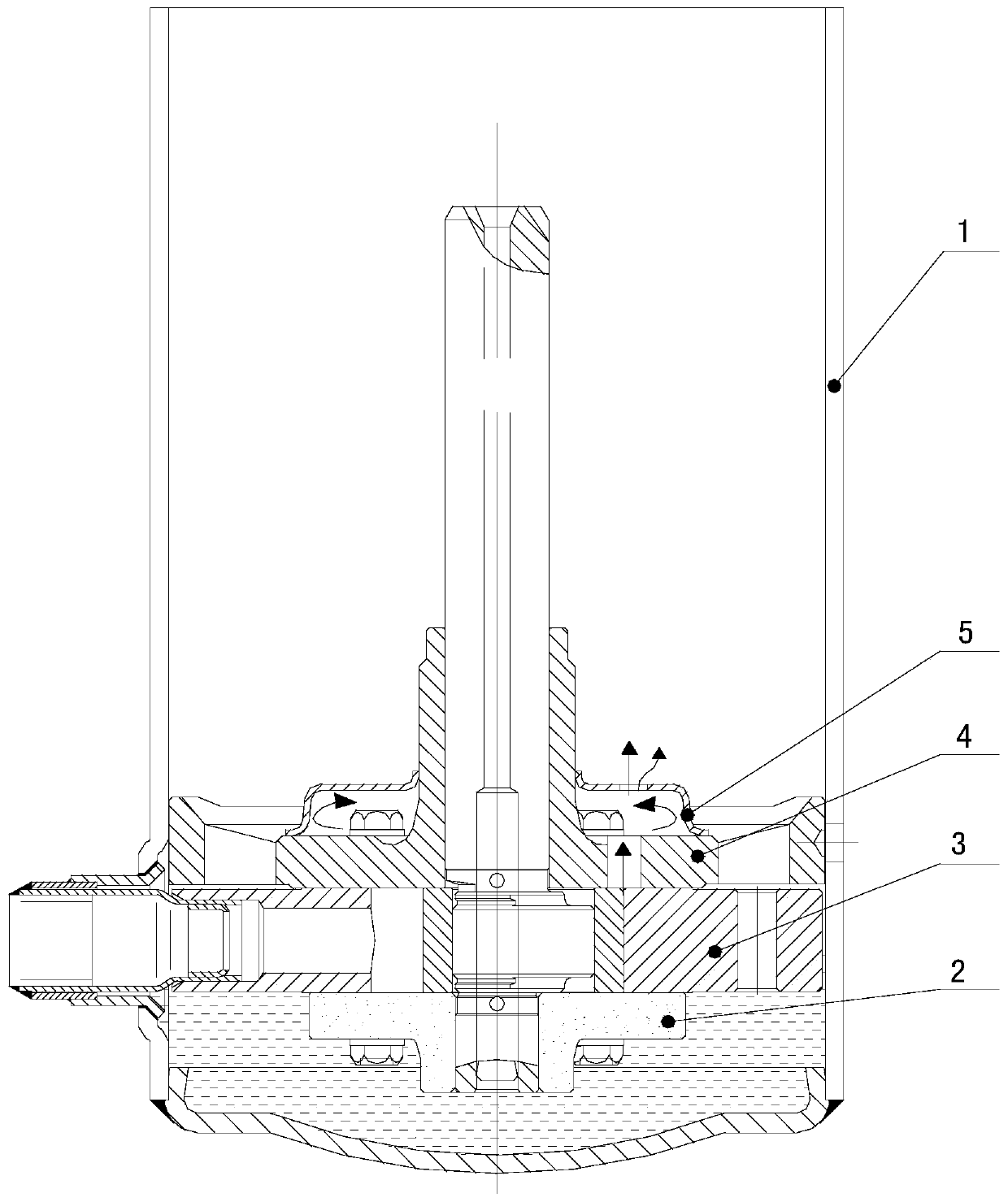

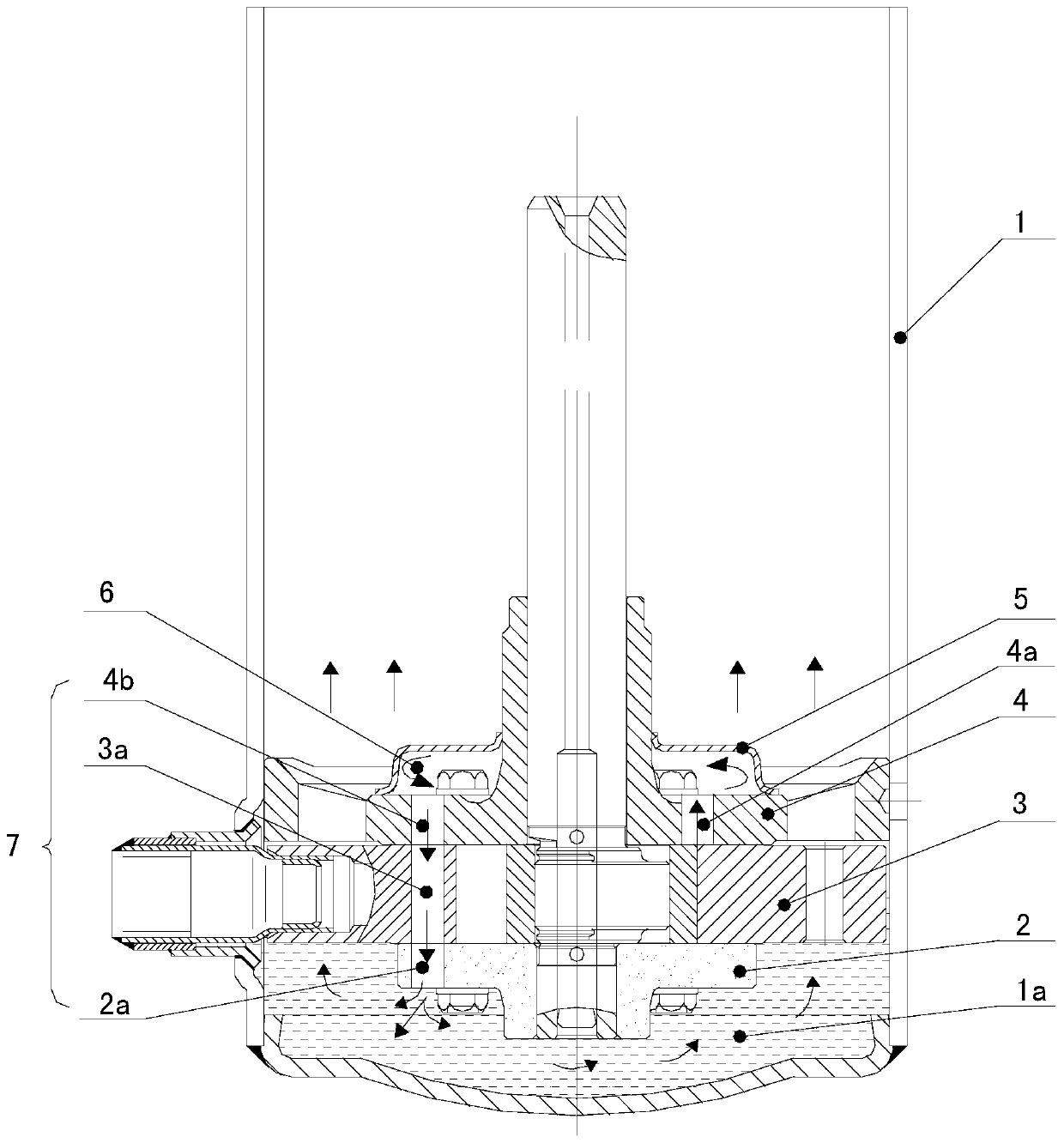

[0025] In one embodiment of the present invention, a compressor exhaust structure is provided, which includes a closed casing, a compression component, a sound-absorbing chamber and an exhaust passage, wherein the closed casing has a cavity for storing lubricating oil at the bottom of the inner cavity. An oil storage pool; a compression component is arranged at the bottom of the inner cavity of the airtight housing, and the compression component has an air suction port and an exhaust port; The port is connected; one end of the exhaust passage is connected with the silencer cavity, and the other end is connected with the oil storage tank. In the compressor exhaust structure of the present invention, the muffler cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com