Packaging materials with reduced ignition propensity properties

A technology of packaging materials and combustion accelerators, applied in the application and manufacture of cigars, tobacco, etc., can solve the problems of the release of tobacco products and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

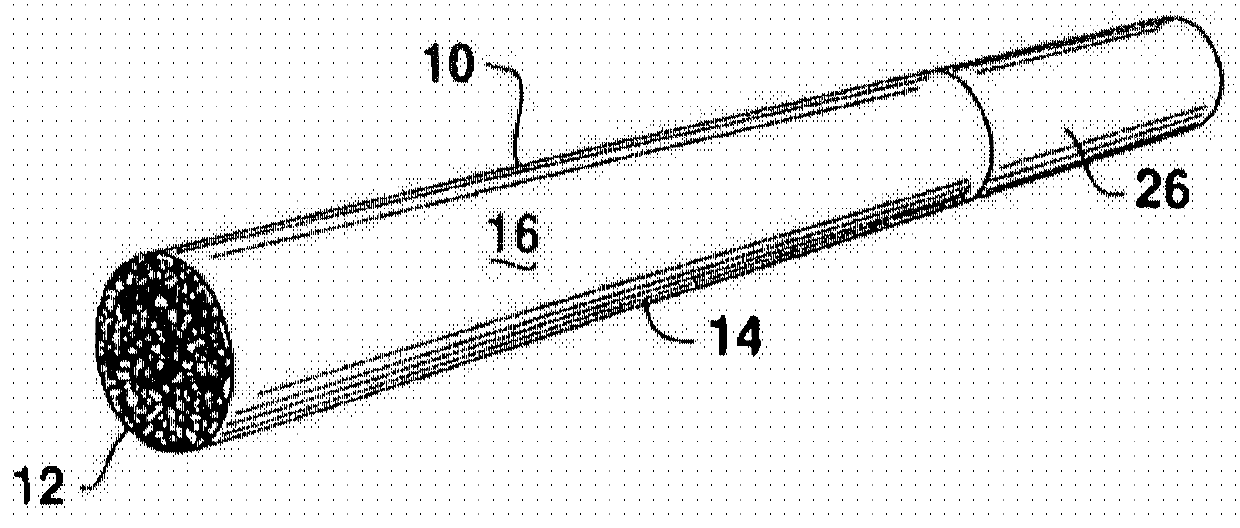

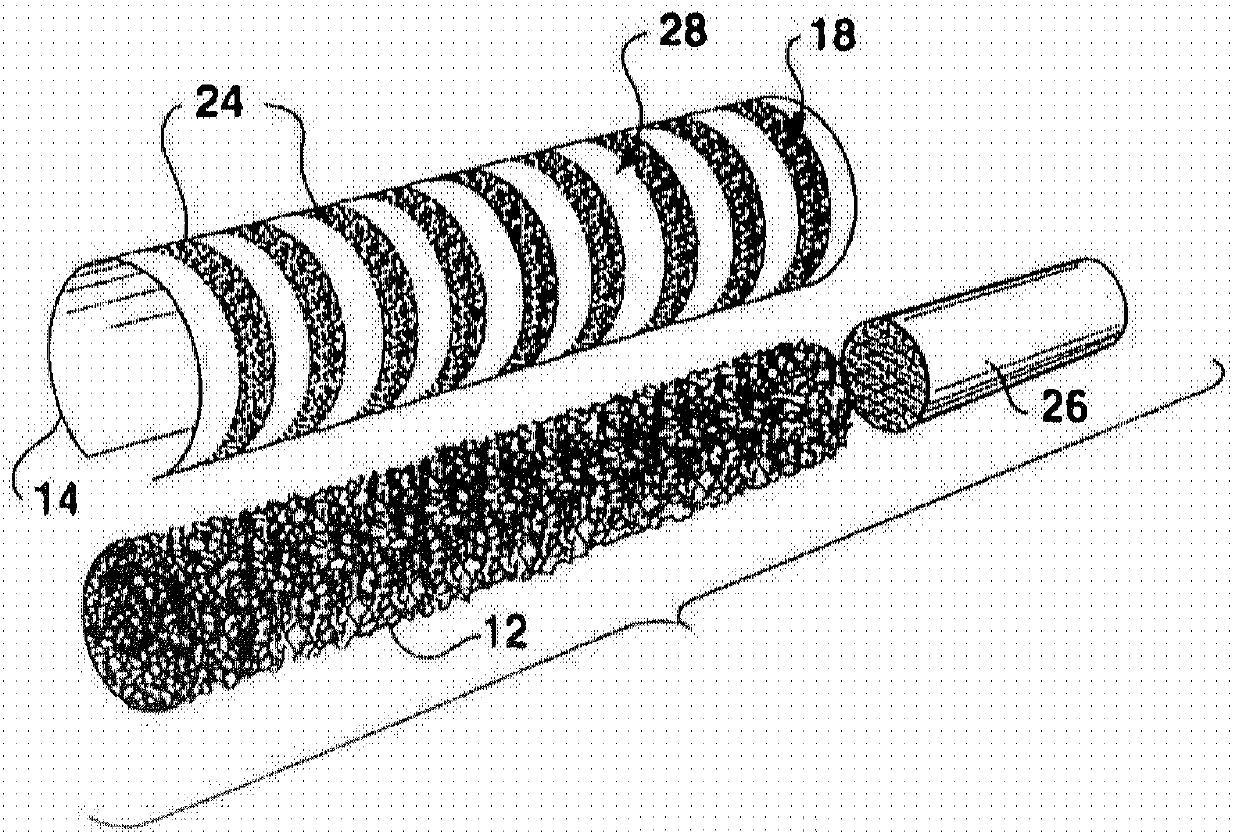

[0117] The following experiments were performed to demonstrate certain teachings of the present disclosure. In this example, commercially available low ignition propensity (LIP) cigarette papers were compared to wrappers made according to the present disclosure. Commercially available packaging materials are treated uniformly over their entire surface with citrate. The tape of the ignition reducing composition is then applied to the packaging material. In contrast, a packaging material is constructed such that the combustion promoter therein is applied only between the ignition reducing strips. The reduced ignition zone is formed by applying alginate to the packaging material.

[0118] The commercially available paper had a permeability of 60CU and was treated with 0.8% mixed citrate. Base paper includes relatively consistent amounts of fiber and filler (calcium carbonate).

[0119] In contrast, tapes of samples made according to the present disclosure were applied to area...

Embodiment 2

[0129]Additional packaging materials were constructed and tested according to some of the experiments described in Example 1 above. In this example, Example 5 below treated its entire surface area with potassium citrate. The tape of the ignition reducing composition is then applied to the packaging material. The tape is made from an alginate composition. Paper packaging materials are made from a mixture of softwood fibers, hardwood fibers and fillers.

[0130] Sample 6 below has no combustion promoter disposed in the reduced ignition zone. In addition, the packaging material includes untreated areas before and after each reduced ignition zone. The untreated area does not have any combustion promoter and has a width of 0.25 mm.

[0131] Packaging material is used to produce cigarettes. Standard American blends are used as cigarette fillers. Cigarettes were constructed such that Sample 5 and Sample 6 had approximately the same ASTM ratio and FASE ratio.

[0132] To obtain...

Embodiment 3

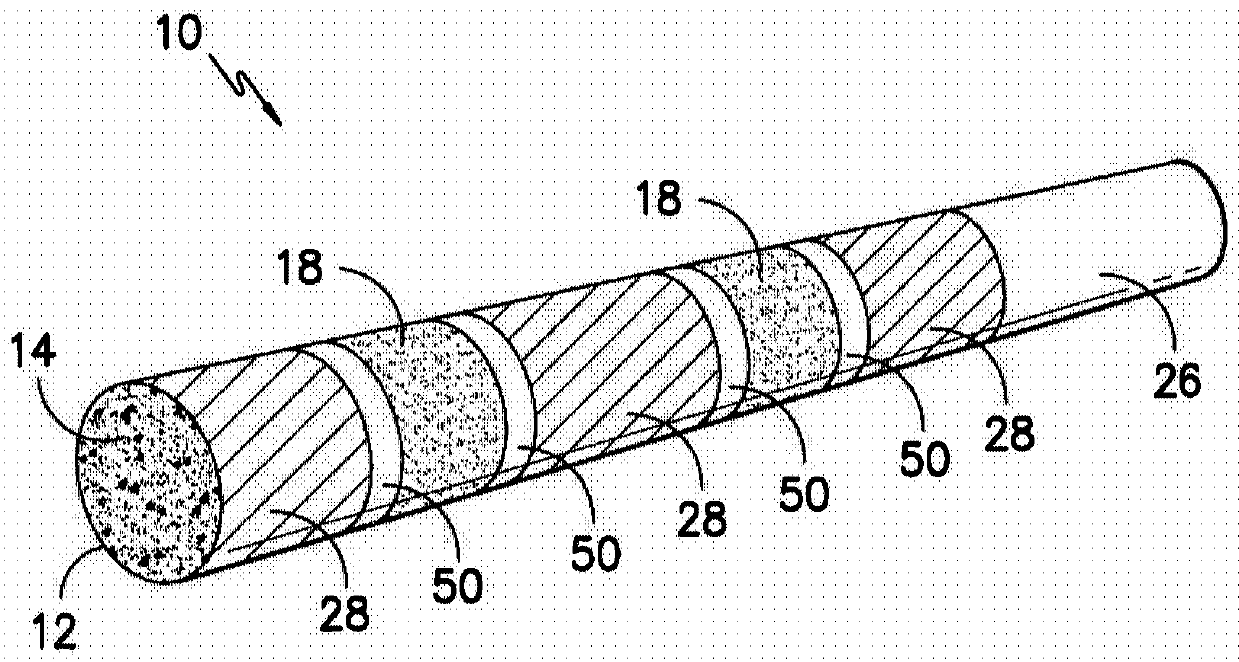

[0138] Additional packaging materials were constructed and tested. Sample 7 was made similar to Sample 5 in Example 2. Sample 8 was made similar to Sample 6 in Example 2. However, Sample 8 had a gap width of 2 mm in the untreated area.

[0139] Sample 9 was made according to the present disclosure and included a "dual tone" citrate treatment. In sample 9, the entire packaging material was first treated with 0.3% by weight sodium citrate. An additional 0.8% by weight of potassium citrate was then applied between the lower ignition zones. In addition, an untreated area or a barrier area having a gap width of 2 mm was formed.

[0140] In this example, the wrapper was constructed with the same band diffusivity at 23° C. using a wrapper with a lower permeability. The following result is obtained.

[0141]

[0142] As shown above, Sample 8 and Sample 9 have significantly better ASTM ratios at the same band diffusivity. Surprisingly, Sample 9 has a better ASTM Ratio and FAS...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com