Medium concave ridging culture method for tobacco

A cultivation method and concave-shaped technology, which is applied in the field of tobacco concave-shaped ridge cultivation, can solve the problems of difficult operation of uncovering the soil, unfavorable mechanized soil cultivation operation, labor and time-consuming problems, and achieve the advantages of mechanized soil cultivation operation and promotion of nutrients Decomposition and moisture absorption, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

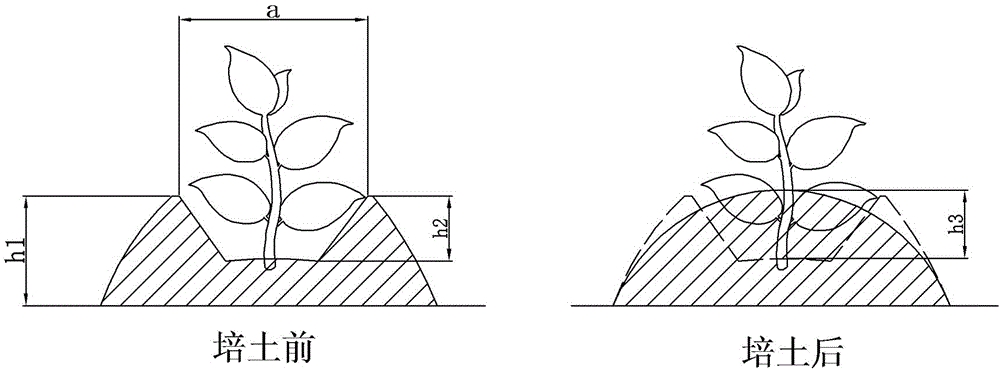

[0023] Embodiment 1: a kind of concave type ridge cultivation method of tobacco, see figure 2 , including the following steps:

[0024] (1) Ridging: A concave-shaped tobacco ridge is formed in the tobacco field. The shape of the concave-shaped tobacco ridge is: the height h1 of the ridge is 30-40cm, and the top of the tobacco ridge is sunken downward, forming the ridge walls on both sides and the depression in the middle , the cross-section of the depression is an inverted trapezoid, the depth h2 of the depression is 20-25cm, and the width a of the upper opening of the depression is 40-60cm; A drainage port, the drainage port communicates the depression with the outside of the smoke ridge;

[0025] (2) Transplanting and film covering: transplant the tobacco seedlings into the depression of the tobacco ridge, and cover the top of the tobacco ridge with thickened plastic film after transplanting. The seedlings are 5-10cm away from the plastic film;

[0026] (3) Remove the fi...

specific Embodiment approach

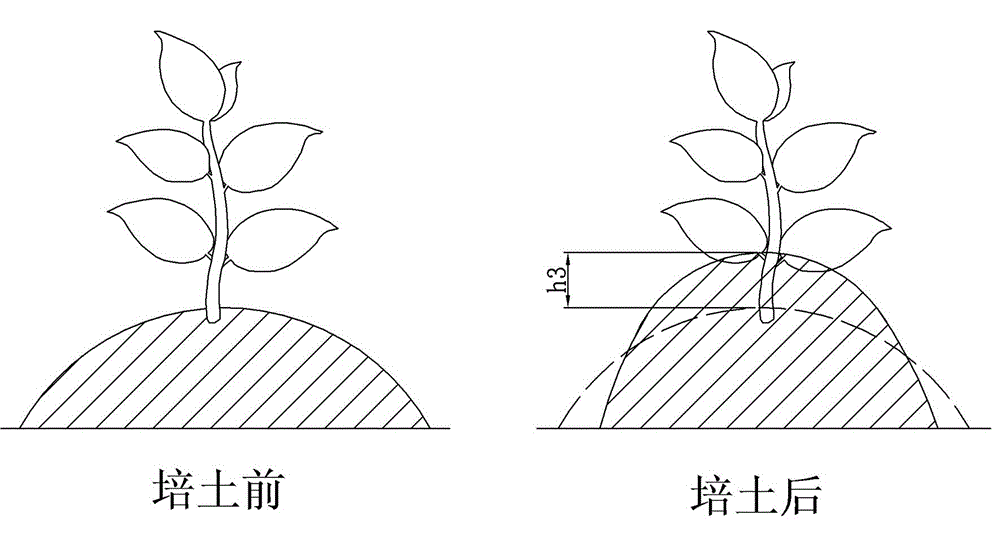

[0029] The existing "turtle-shaped" tobacco ridge cultivation method usually has a width of 110-130cm and a height of 20-30cm, and the tobacco seedlings are directly transplanted on the arc-shaped top of the ridge, see figure 1 When cultivating soil, the soil needs to be cultivated on the top of the tobacco ridge. Since the top of the tobacco ridge itself is arc-shaped, the new soil on the upper part is easy to slide down along the sides of the tobacco ridge when cultivating soil, and the stem position of the tobacco plant cluster is relatively high in the later stage, so soil cultivation The operation is labor-intensive and time-consuming, which is not conducive to the operation of mechanical soil cultivation. In addition, the height of soil cultivation is also limited. Usually, the height of soil cultivation h3 is not easy to exceed 10cm. The plastic film mulching technology that matches this kind of tobacco ridge cultivation method is to cover the tobacco ridge with plastic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com