Flue-cured tobacco transplanting method

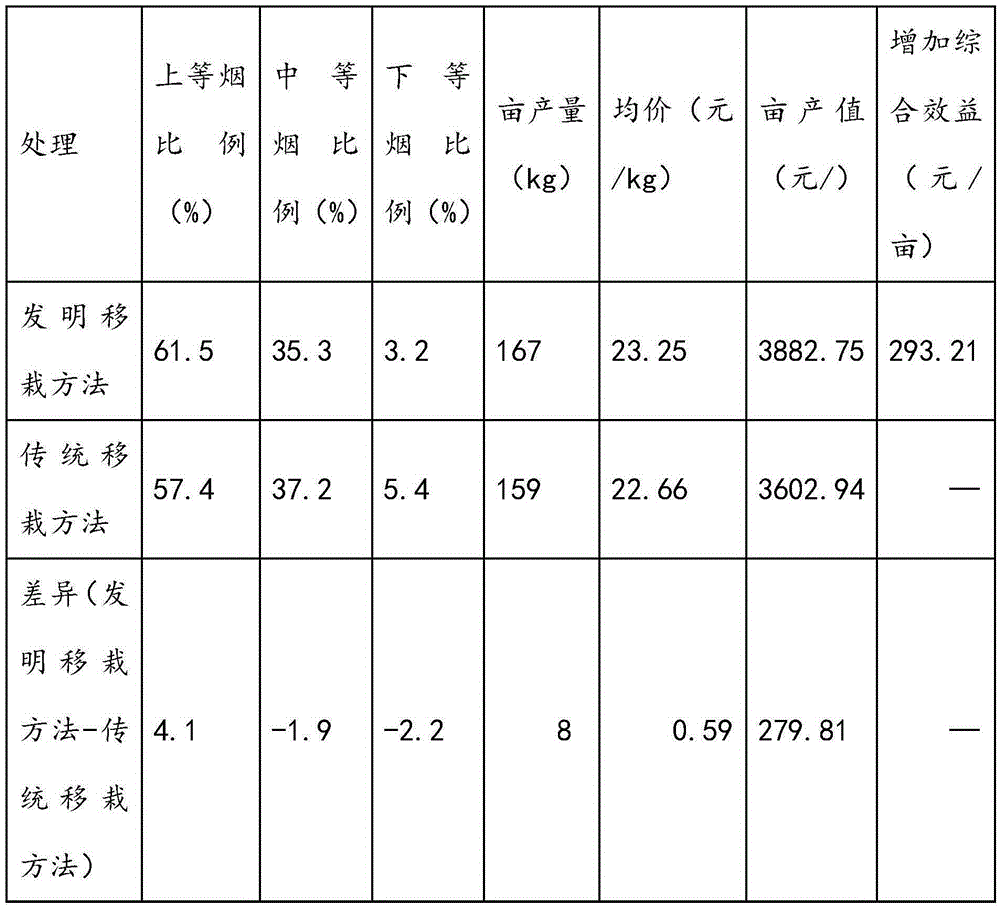

A flue-cured tobacco and pre-transplanting technology, applied in botany equipment and methods, cultivation, plant cultivation, etc., can solve the problems of tobacco and rice stubble, low transplanting efficiency, and low quality of tobacco leaves after curing, so as to promote comprehensive The improvement of benefits, the improvement of the long time of returning seedlings, and the effect of improving the quality of tobacco leaves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

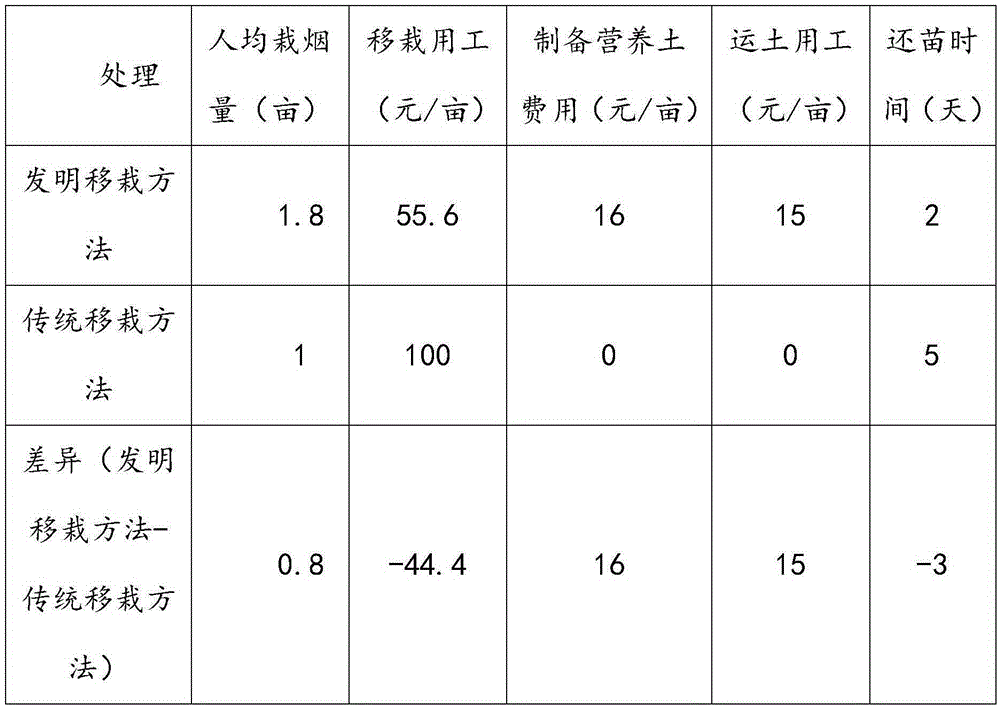

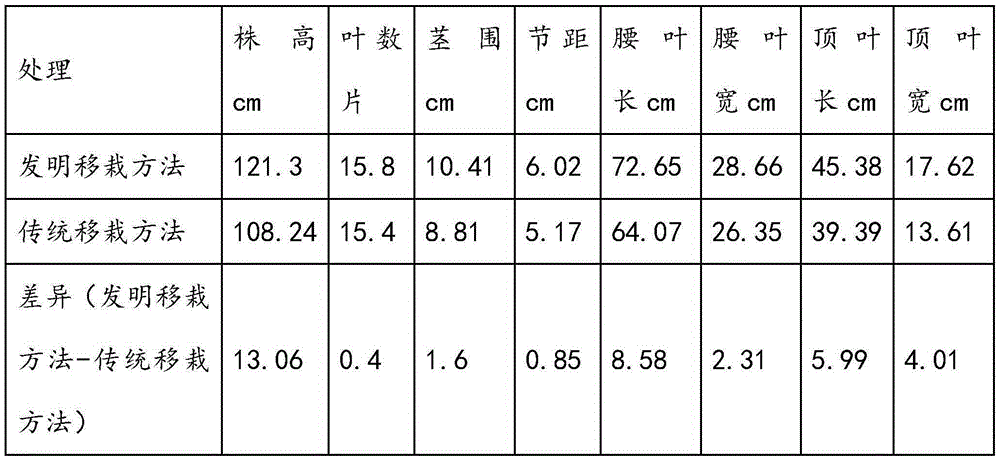

[0020] On the basis of conventional planting and transplanting technology, the invention improves in the transplanting stage, increases the links of nutrient soil preparation and soil-throwing and planting, and adopts a streamlined operation procedure.

[0021] Treatment basis: The long-term rice planting in the southern tobacco area leads to the heavy soil texture. After soil preparation, there are generally problems that the soil is not finely divided, the depth of the transplanting hole is not enough, and the planting cannot be deeply planted. During transplanting, bamboo chips are used manually in the transplanting process. Agitating the soil in the hole to cover the roots of the tobacco seedlings is prone to the phenomenon that the roots of the tobacco seedlings are hanging in the air, the soil cannot completely wrap the roots, the time for the seedlings to return is long, or even the seedlings die. The labor cost of transplanting is high, the transplanting quality of toba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com