Device and method with pot seedling feeding speed capable of being adjusted automatically

An automatic adjustment, pot seedling technology, applied in planting methods, transplanting machinery, cultivation and other directions, can solve the problems of discontinuous feeding and placing pot seedlings, high labor intensity, lowering quality of transplanting, etc., to avoid frequent repetitive actions, reduce The effect of low labor intensity and improved transplanting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The structure, principle and working process of the present invention will be further described below in conjunction with the accompanying drawings.

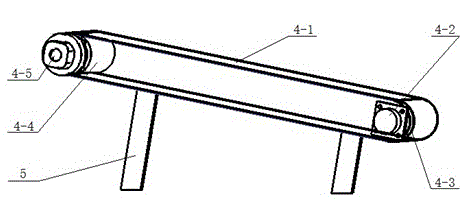

[0020] figure 1 It is a schematic structural view of the pot seedling shovel 1 in the device for automatically adjusting the pot seedling feeding speed of the present invention. The pot seedling shovel 1 is convenient for the operator to quickly put multiple pot seedlings into the transmission unit 4 for transporting pot seedlings at one time.

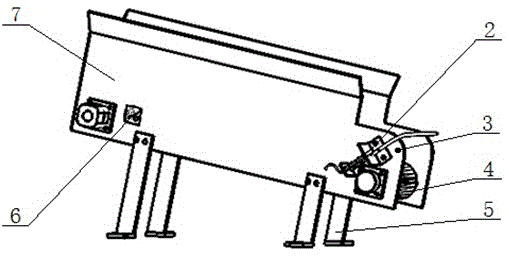

[0021] figure 2 A schematic diagram of the structure of a device that can automatically adjust the feeding speed of pot seedlings provided by the present invention. The seedling system is installed and fixed on the bracket 5 of the transplanting machine; it contains a seedling separation unit 2 for separating seedlings and straightening the feeding posture of pot seedlings and a detection sensor 3 for detecting whether the pot seedlings have reached the position of separating se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com