Elastic chuck

A collet and elastic technology, applied in the field of elastic collets, can solve the problems of complex design and structure, large number of parts and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

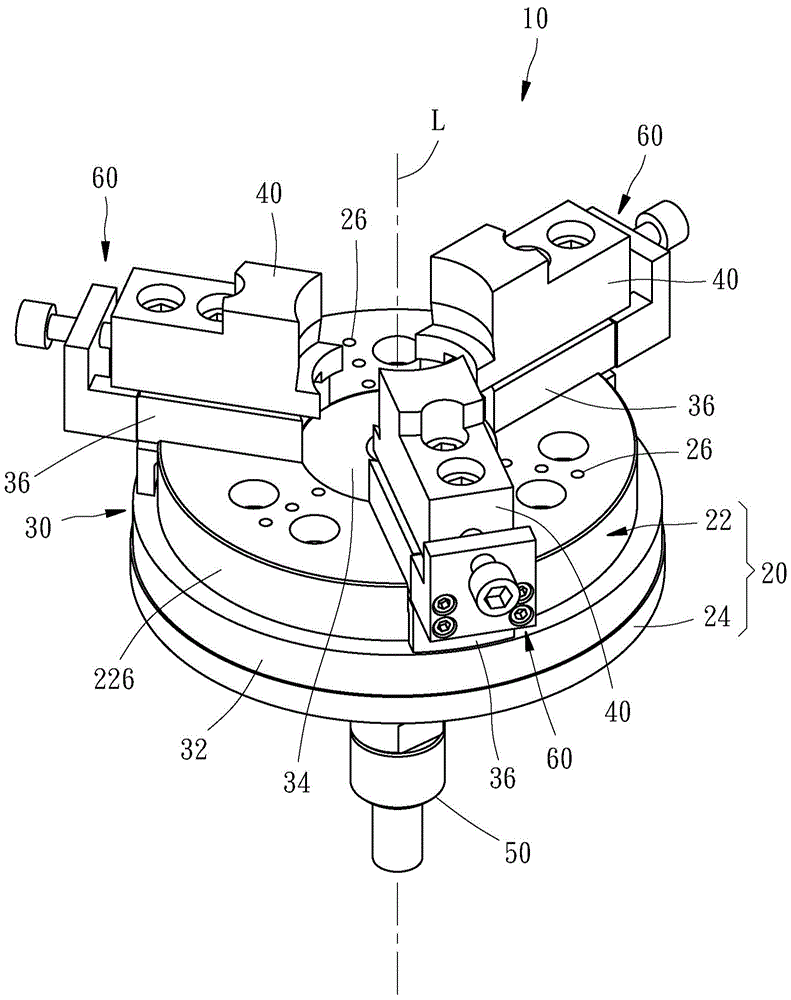

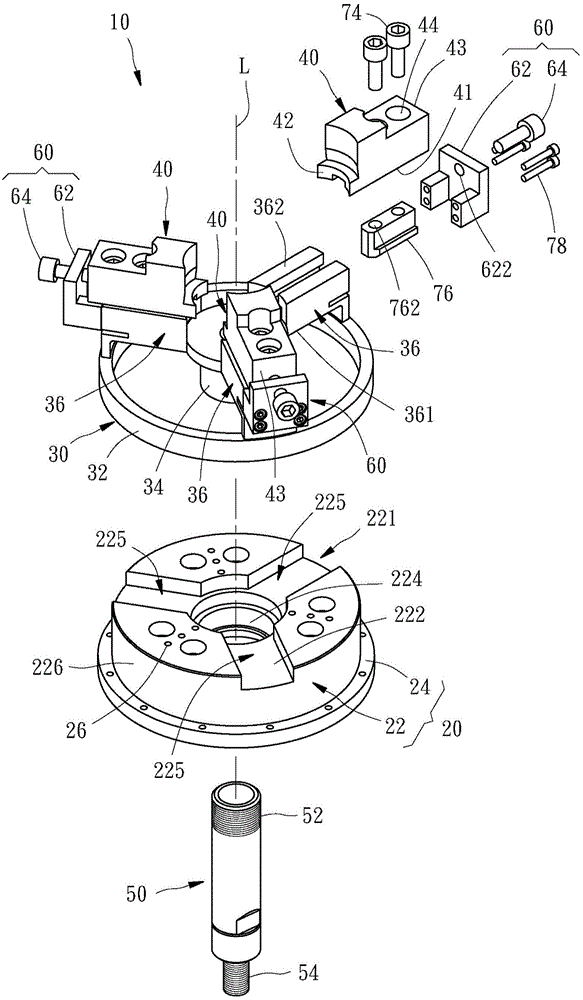

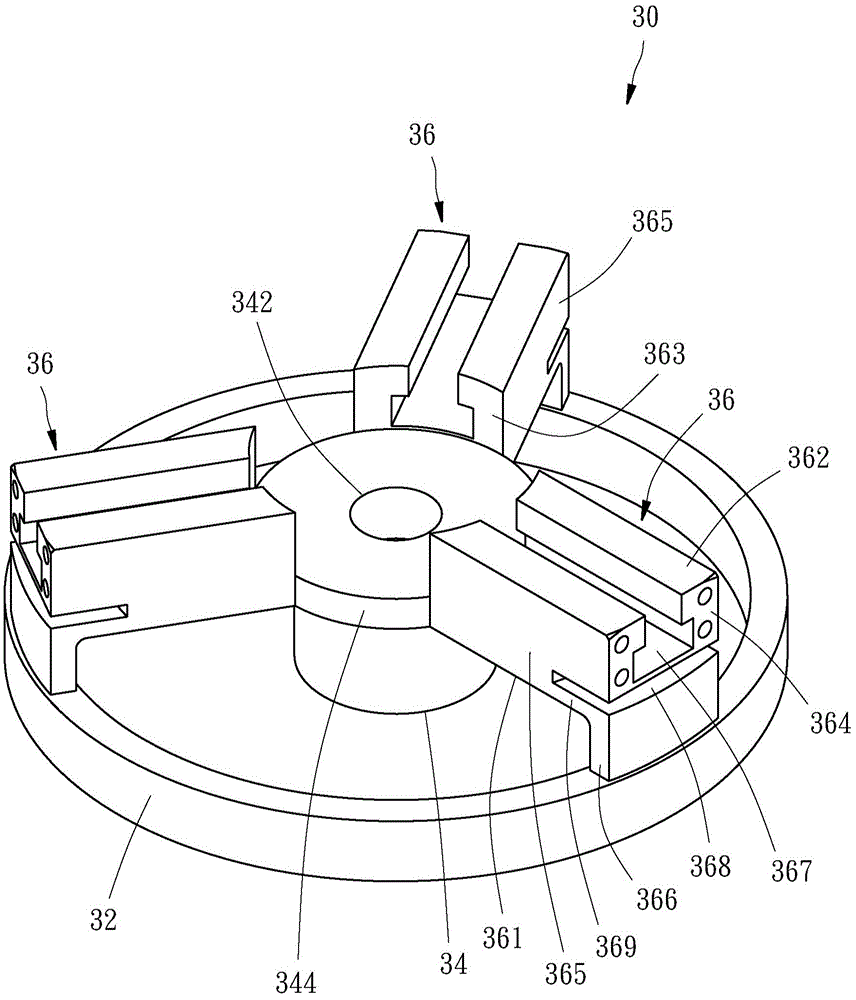

[0039] Please refer to the accompanying drawings, the elastic chuck 10 provided by a preferred embodiment of the present invention includes a chassis 20, an elastic disc 30, three jaws 40, and three stop units 60, and the elastic chuck 10 is used for a The pull rod 50 is connected to receive the tension provided by the pull rod 50 to clamp a workpiece (not shown in the figure).

[0040] The chassis 20 includes a disc-shaped body 22 and a ring-shaped protrusion 24 . The main body 22 has a radial groove 221, an upper surface 222 located in the groove 221, a lower surface 223 facing the opposite direction from the upper surface 222, and a through the upper surface 222 and the lower surface 223. The through hole 224 can define an imaginary central axis L. The groove 221 communicates with the through hole 224 and has three accommodating portions 225 radially distributed around the through hole 224 . The protrusion 24 integrally protrudes from the outer peripheral surface 226 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com