Robot for carrying, assembling and moving heavy loads

A mobile robot and robot technology, applied in manipulators, manufacturing tools, etc., can solve problems such as complex application conditions, poor adaptability and flexibility, and achieve the effect of expanding practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

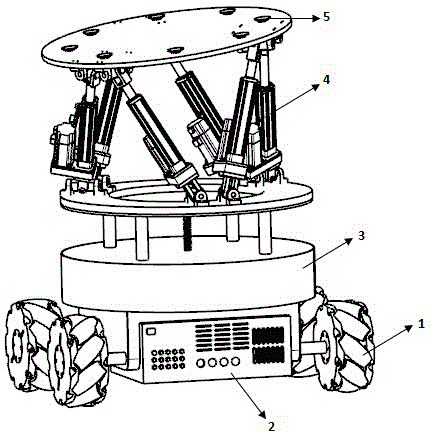

[0019] see figure 1 , a mobile robot for heavy-duty handling and assembly, including a Mecanum wheeled omnidirectional mobile platform 1, a control cabinet 2, a lifting mechanism 3, a Stewart platform 4, and a clamping device 5; the control cabinet 2 and the Mecanum wheeled The omnidirectional mobile platform 1 is connected, the lifting mechanism 3 is fixedly connected with the Mecanum wheeled omnidirectional mobile platform 1, the Stewart platform 4 is fixedly installed on the lifting mechanism 3, and the clamping device 5 is fixedly installed on the Stewart platform 4 on.

[0020] The control cabinet 2 is installed in the body of the Mecanum wheeled omnidirectional mobile platform 1, so as not to affect the movement of the entire mobile robot; the control cabinet 2 integrates the controller of the Mecanum wheeled omnidirectional mobile platform 1 and the lifting mechanism 3 Controller as well as the Stewart platform 4 controller.

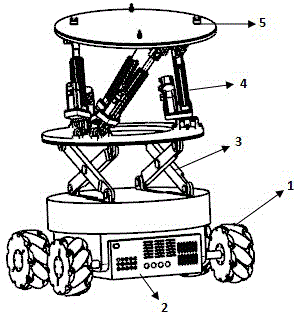

[0021] Such as figure 1 with image 3 S...

Embodiment 2

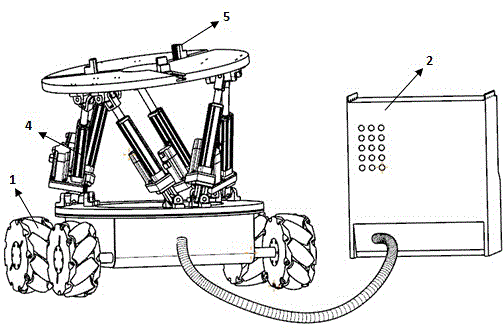

[0032] see figure 2 , the control cabinet 2 is independently and fixedly installed in the workplace, and connected to the car body through cables, which is suitable for the situation when the robot's moving range is small. The elevating mechanism 3 is not selected, the clamping device 5 is selected as a chuck, and the operation steps of Embodiment 1 can be repeated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wheel diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com