Mechanical type all-electric servo numerical control bending machine based on multi-degree-of-freedom coupling driving

A coupled drive and mechanical technology, applied in metal processing, metal processing equipment, forming tools, etc., can solve the problems of low power utilization, high drive motor power, and incomplete application of motor power, so as to improve performance and action Gently, to achieve the effect of high-speed heavy load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

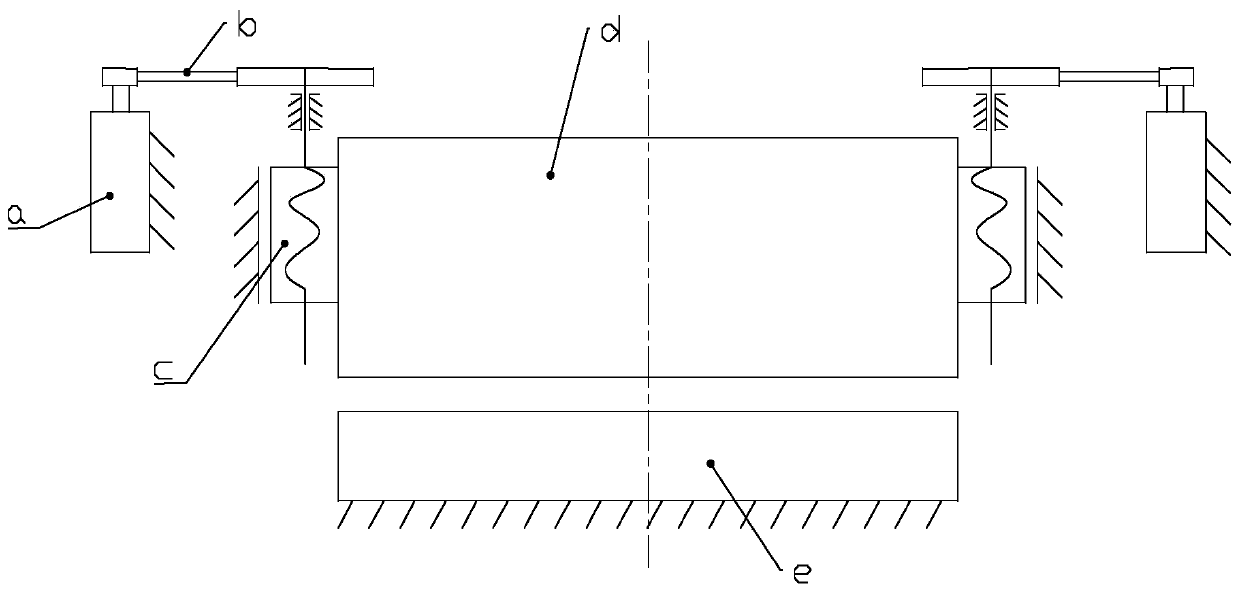

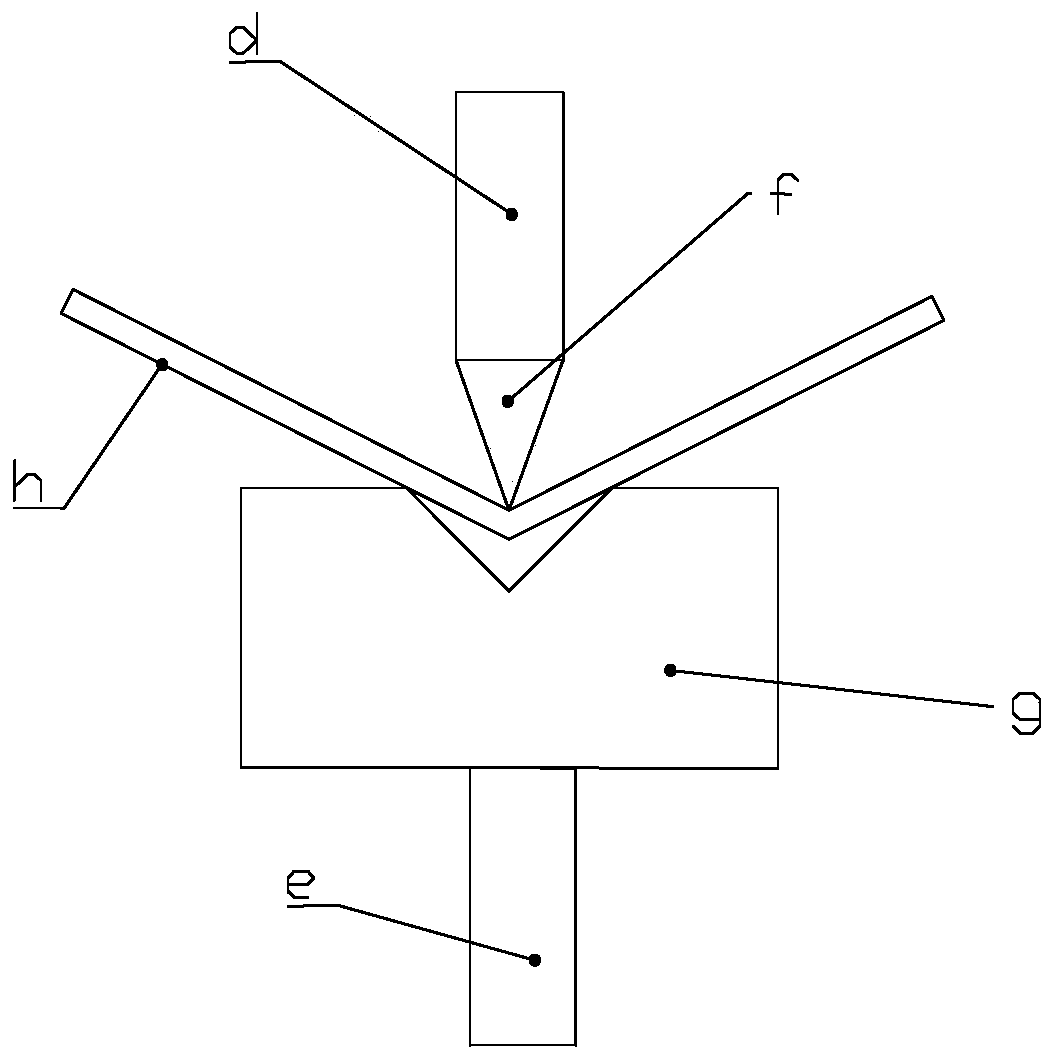

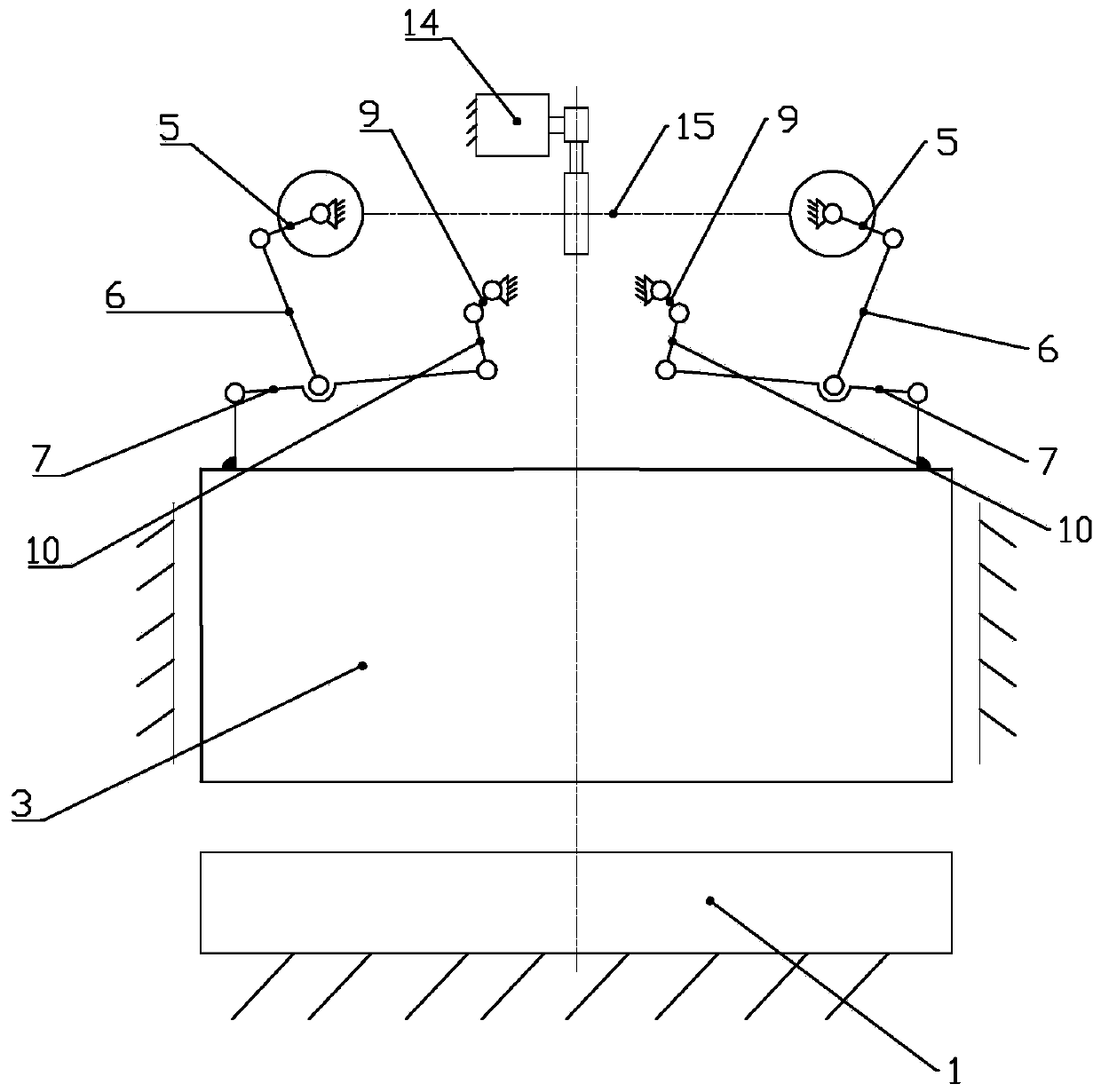

[0060] Such as image 3 As shown, the present invention is a mechanical all-electric servo numerical control bending machine based on multi-degree-of-freedom coupling drive, including a frame 1, a lower die 2, a slider 3, and a lower die 4. The sliding block 3 can move up and down along the frame 1. The sliding block 3 is provided with symmetrical guide grooves 24 for guiding sliding. The frame 1 is provided with a guide block inserted into the guiding groove 24 and sliding up and down along the guiding groove 24. 25. The upper mold 4 is fixedly arranged on the slider 3, the lower mold 2 is fixedly arranged on the frame 1, and the upper mold 4 and the lower mold 2 cooperate with each other to realize bending.

[0061] Such as Figure 4 with Figure 5 As shown, the slider 3 is connected with a first drive mechanism and a second drive mechanism for driving the slider to achieve different speeds and stroke ranges. The first driving mechanism includes a first power assembly, a first...

Embodiment 2

[0072] The structure of the second embodiment is the same as that of the first embodiment. The difference is that the eccentricity of the first eccentric wheel 5 is smaller than that of the second eccentric wheel 9, and the first driving mechanism drives the slider to realize low-speed and small-stroke movement. The second drive mechanism drives the slider to achieve high-speed and large-stroke movement. The working condition of the bending machine is a typical variable-speed and variable-load working condition. The fast down and return stages are high-speed, low-load and large-stroke movement stages, and the work advance stage is a low-speed, large-load and small-stroke movement stage. Therefore, the present invention adopts the second drive mechanism to drive the slider to realize the fast down and return stages, and the first drive mechanism drives the slider to realize the work advance stage.

Embodiment 3

[0074] Such as Figure 14 As shown, the present invention is a mechanical all-electric servo numerical control bending machine based on multi-degree-of-freedom coupling drive, which includes a frame 1, a lower die 2, a slider 3, and a lower die 4. The sliding block 3 can move up and down along the frame 1. The sliding block 3 is provided with symmetrical guide grooves 24 for guiding sliding. The frame 1 is provided with a guide block inserted into the guiding groove 24 and sliding up and down along the guiding groove 24. 25. The upper mold 4 is fixedly arranged on the slider 3, the lower mold 2 is fixedly arranged on the frame 1, and the upper mold 4 and the lower mold 2 cooperate with each other to realize bending.

[0075] Such as Figure 15 with Figure 16 As shown, the slider 3 is connected with a first drive mechanism and a second drive mechanism for driving the slider to achieve different speeds and stroke ranges. The first driving mechanism includes a first power assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com