Tool conveying mechanical arm

A technology for manipulators and workpieces, applied in the field of workpiece conveying manipulators, can solve problems such as low transmission efficiency and complex transmission structure, achieve the effects of reducing weight, simplifying transmission structure, and avoiding strong impact

Inactive Publication Date: 2010-11-24

YANGZHOU METALLURGICAL MACHINERY

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The transmission structure of the above-mentioned workpiece conveying manipulator is complicated, and the transmission efficiency is low, so it is only suitable for light-load and low-speed occasions

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

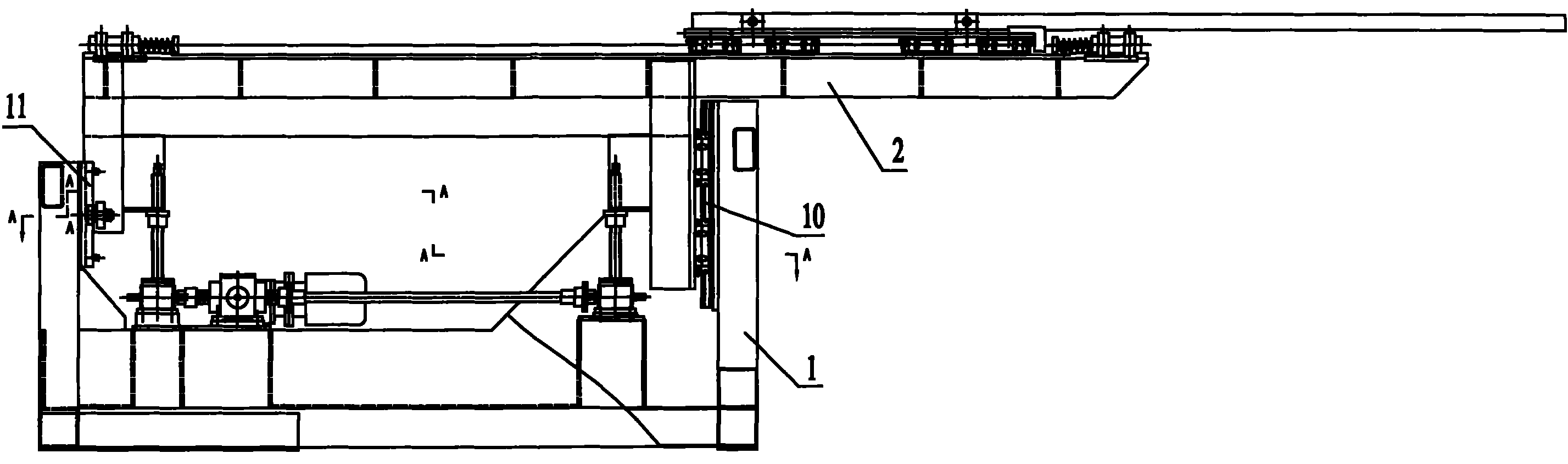

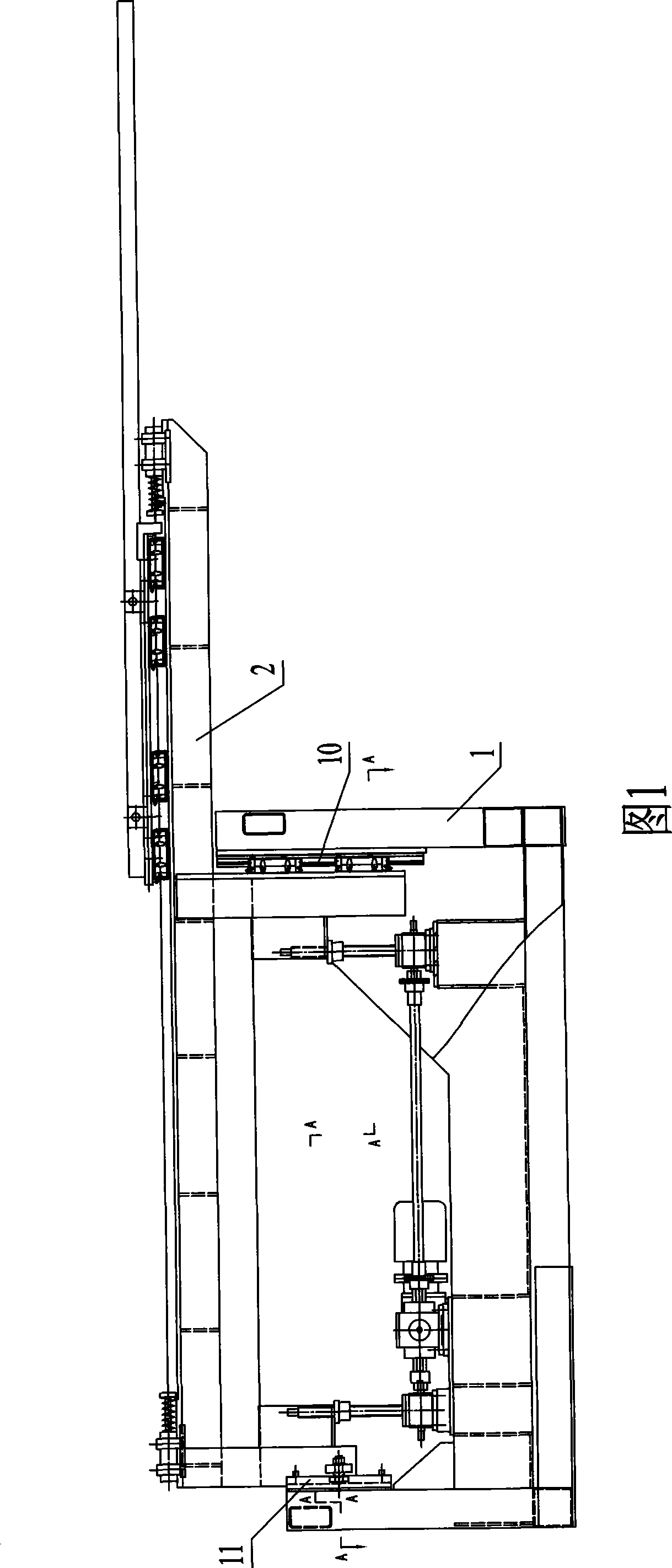

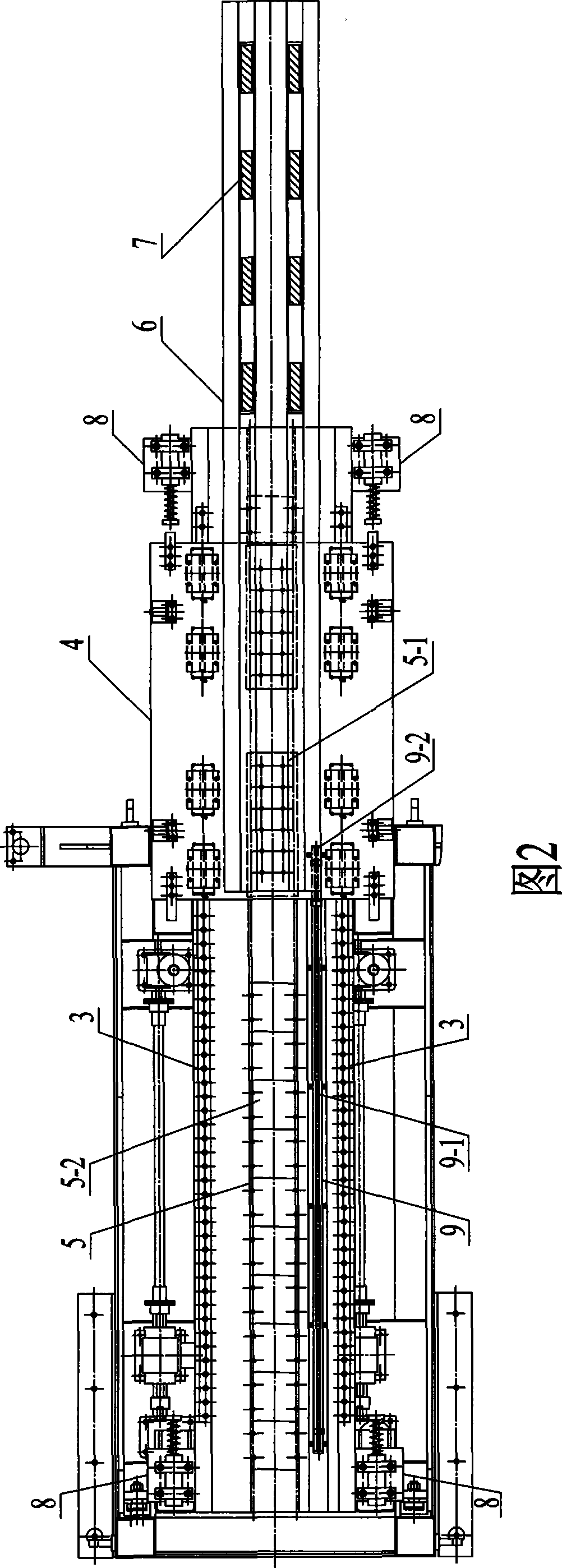

The invention discloses a workpiece conveying manipulator used for forging mechanical automatic equipment in the technical field of forging mechanical automatic equipment. The workpiece conveying manipulator comprises a frame, a linear motor, a horizontal linear guide way, a manipulator and a take-up hand, wherein, the manipulator is arranged on the upper surface of the frame; the linear guide way is connected with the frame in a sliding way through the horizontal linear guide way; the linear motor is arranged between the manipulator and the frame so as to drive the manipulator to reciprocatealong the horizontal linear guide way; and the take-up hand is connected on the manipulator. The workpiece conveying manipulator has the advantages of simple driving structure and high driving efficiency, and is applicable to burden high-speed occasions.

Description

A workpiece conveying manipulator technical field The invention belongs to the technical field of forging machinery automation equipment, and in particular relates to a workpiece conveying manipulator used for forging machinery automation equipment. Background technique The workpiece conveying manipulator used on the existing forging machinery is usually driven by a servo motor or a stepping motor to drive a rolling screw, a synchronous toothed belt, a rack and pinion and other actuators to complete the conveying of the workpiece. The transmission structure of the above-mentioned workpiece conveying manipulator is complicated, and the transmission efficiency is low, so it is only suitable for occasions with light load and low speed. Contents of the invention The technical problem to be solved by the present invention is to provide a workpiece conveying manipulator with simple transmission structure and high transmission efficiency, which can be applied to heavy-load and...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B25J15/00B25J3/04B25J15/06

Inventor 程洪波孙成建贾鲁宁

Owner YANGZHOU METALLURGICAL MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com