Fuel-self-balancing-based bed temperature control system and method for circulating fluidized bed boiler

A circulating fluidized bed, self-balancing technology, applied in the combustion method, fluidized bed combustion equipment, fuel burning in the molten state, etc., can solve the problems of easy local overtemperature and uneven furnace bed temperature distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The preferred embodiments will be described in detail below in conjunction with the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

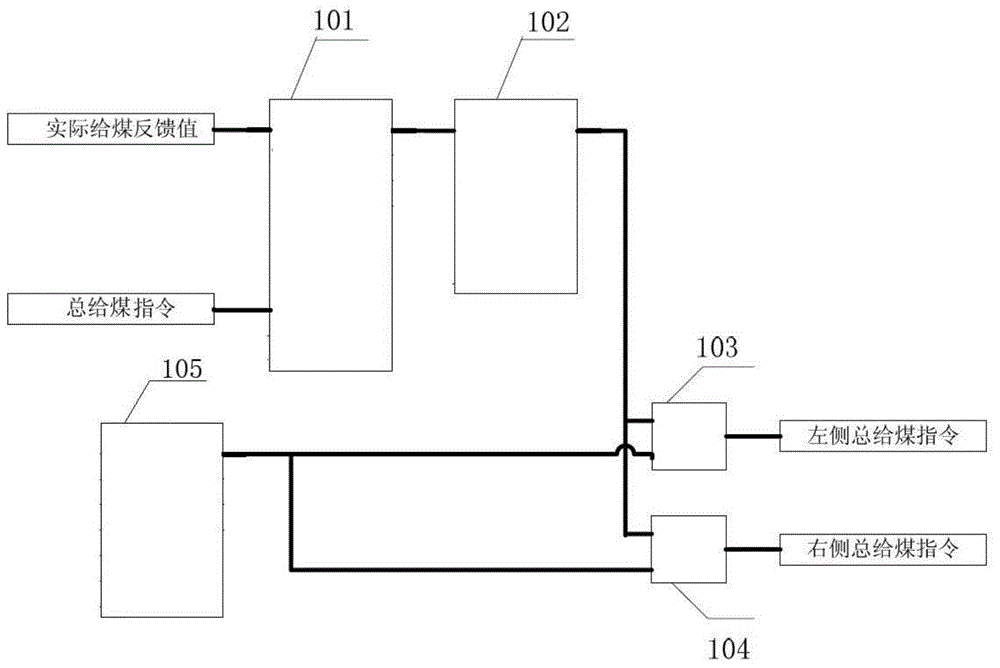

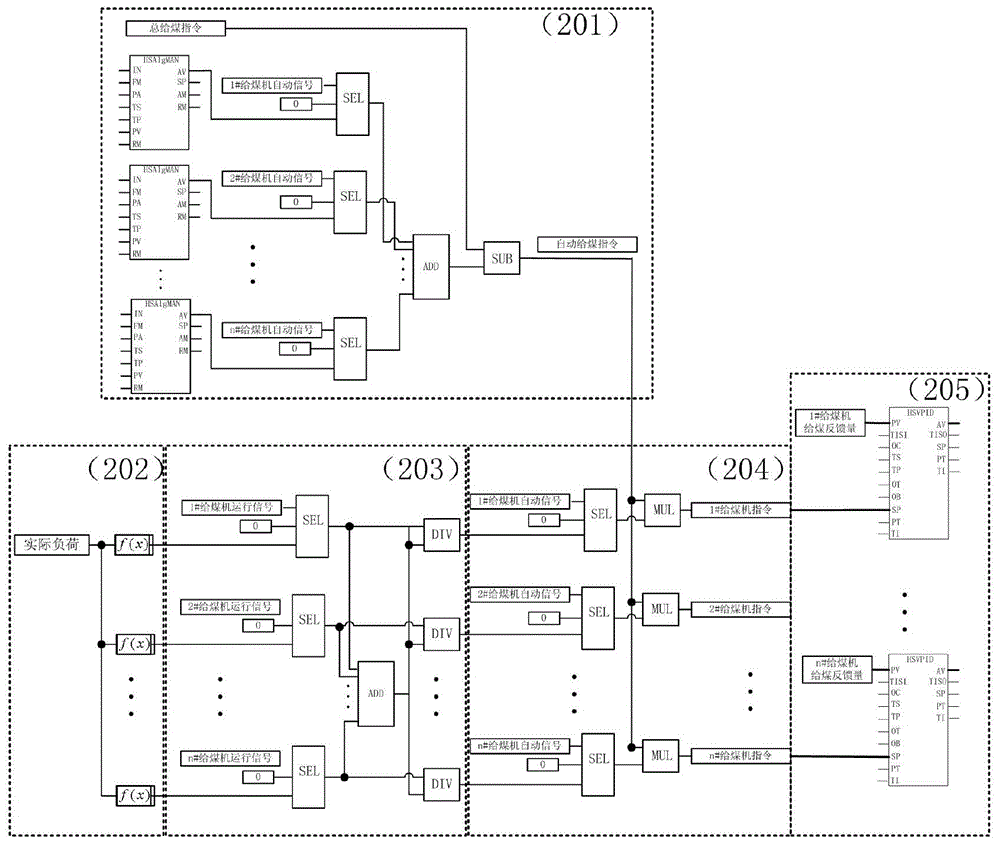

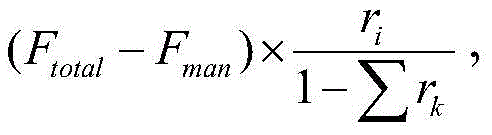

[0034] This example is a fuel self-balancing based circulating fluidized bed boiler bed temperature control method. figure 1 It is a principle diagram of the coal feeding main control adjustment loop of a fuel self-balancing circulating fluidized bed boiler bed temperature control method provided by the present invention. As shown in the figure, the coal feeding main control regulation loop includes a PID regulator unit 101 , a first handheld controller regulation unit 102 , a subtractor 103 , an adder 104 and a second handheld controller regulation unit 105 . The main control loop for coal supply receives the total coal supply command output from the main control of the boiler and the actual feedback of each coal fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com