Smoke ventilator

A range hood and oil fume technology, which is applied in the self-cleaning field of range hoods and range hoods, can solve the problems of affecting service life, affecting air flow, and little research on the installation position, so as to achieve the effect of convenient heating and avoiding accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, scheme and beneficial effect of the present invention more clear, the present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments. Individual drawings may not be accurate enough, in this case, please refer to the text description.

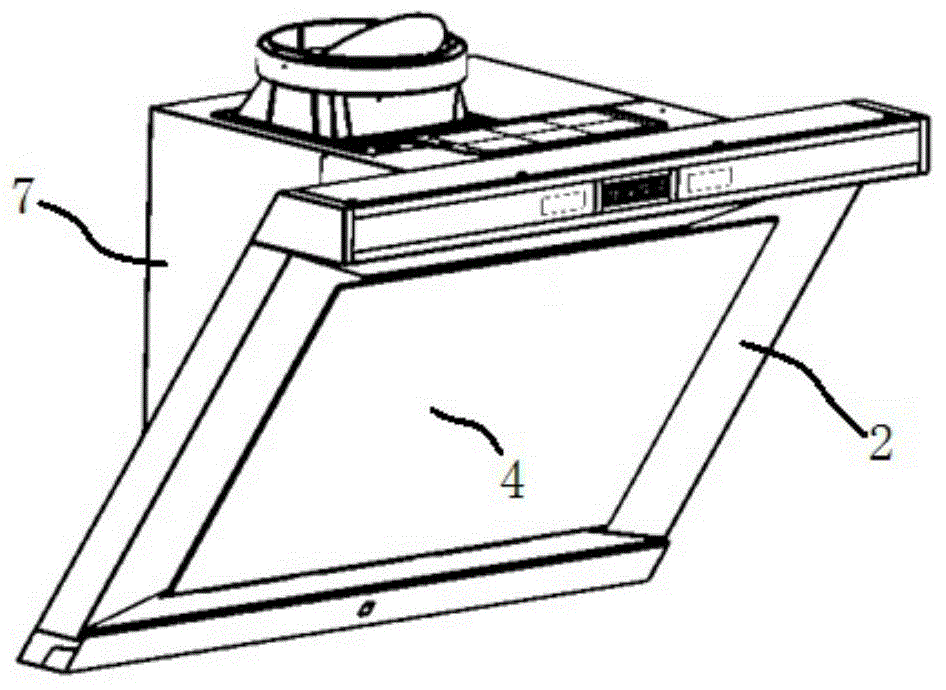

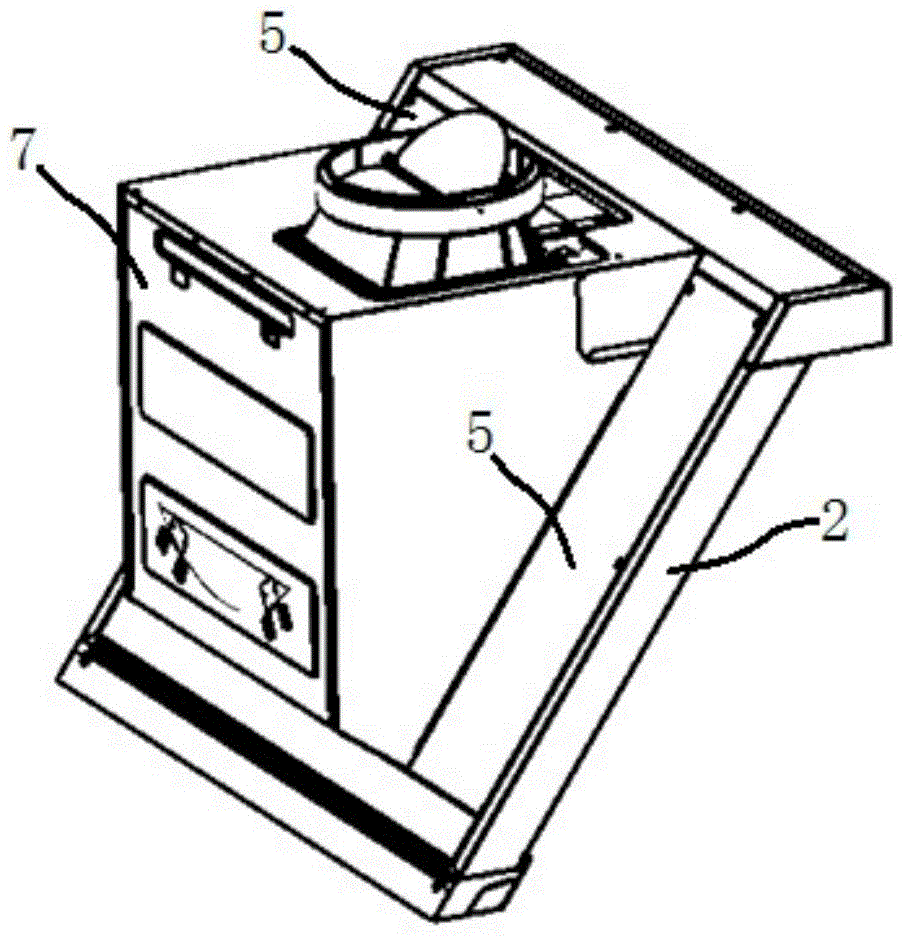

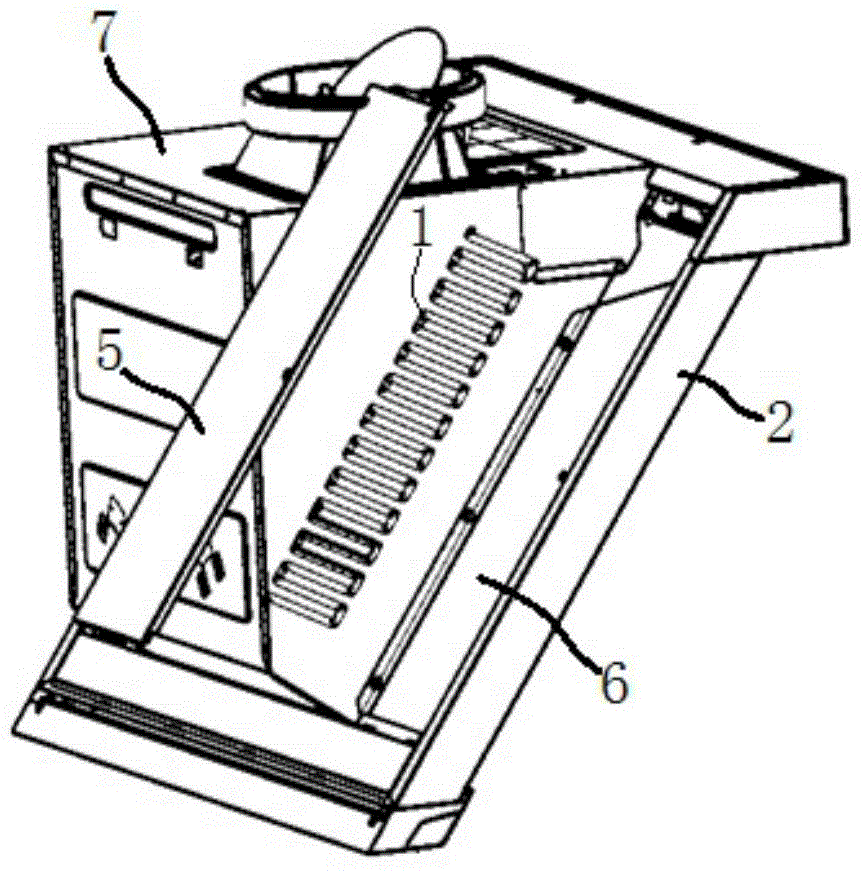

[0028] The present invention proposes an embodiment of a range hood, such as Figures 1 to 4 As shown, it includes a housing part, a filter device 3 , a volute, a heating unit, a filter plate 4 and two cover plates 5 . The housing part further includes a smoke collecting part 2 and a volute housing part 7 , and the smoke collecting part 2 and the volute housing part 7 are connected together. The volute housing part 7 is used for accommodating and placing the volute. The smoke collecting part 2 adopts a side suction type structure, that is, the range hood is a side suction type range hood. The smoke collecting part 2 is used to gather the oily fumes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com