USB (universal serial bus) type-C (connector)

A connector and contact part technology, applied in the direction of connection, parts and electrical components of the connection device, etc., can solve the problems of slow sticking insulating film, affecting product output, low production efficiency, etc., to improve product stability, reduce The effect of high mold cost and quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

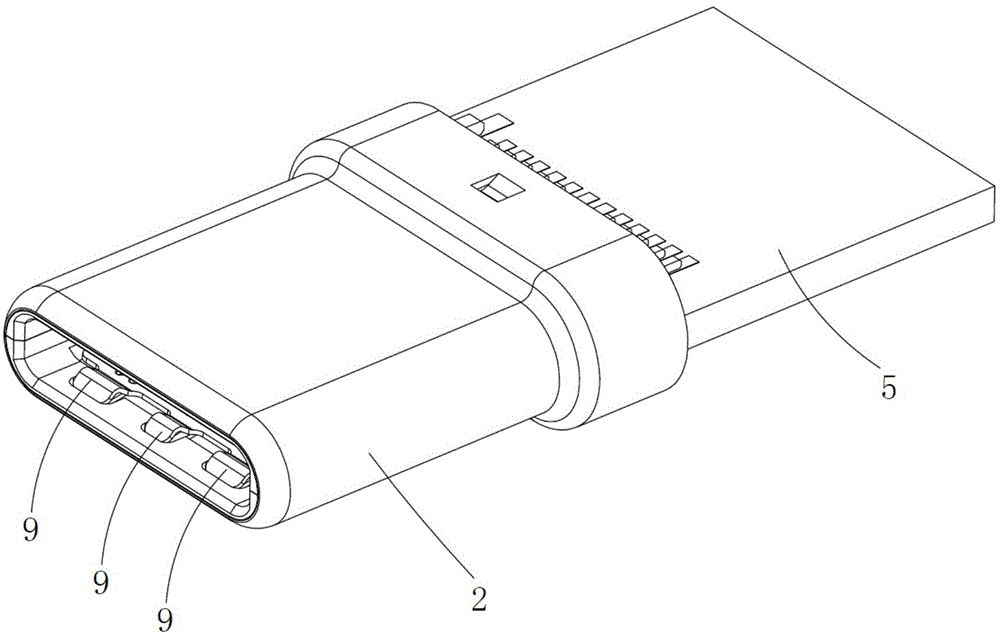

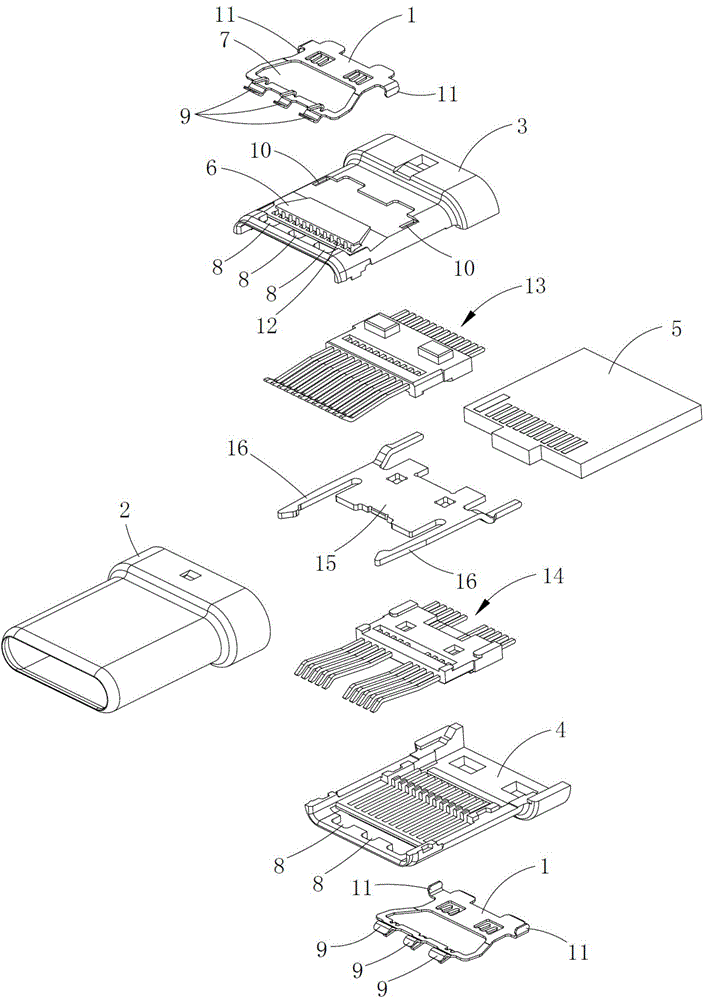

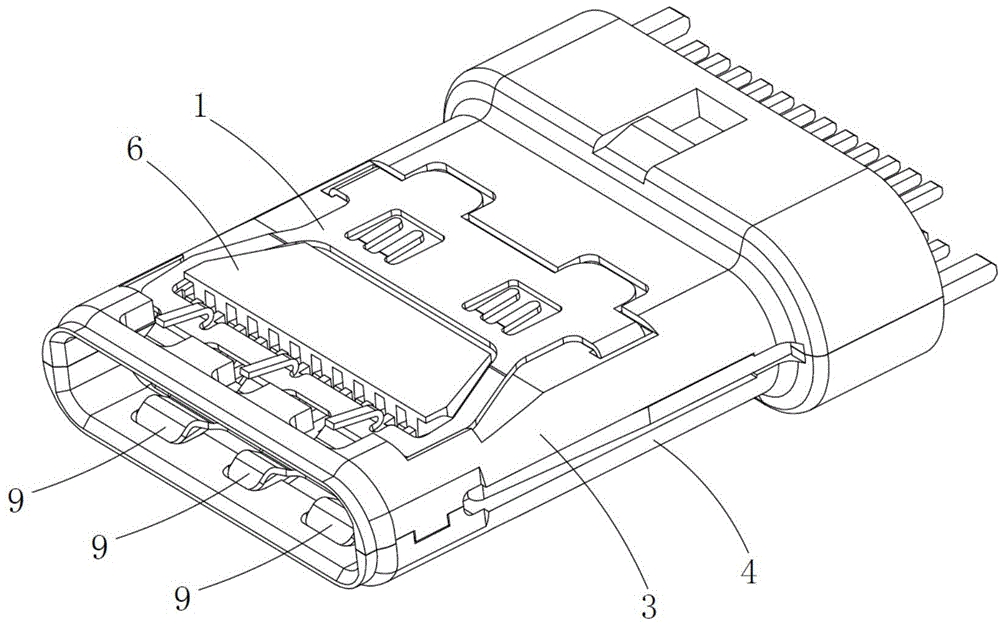

[0026] Examples, see Figure 1 to Figure 4 As shown, a USB Type-C connector includes a terminal assembly, an EMC shrapnel 1, a metal shell 2, an upper cover 3 of a main body rubber core, and a lower cover 4 of the main body rubber core. The terminal assembly includes an upper terminal block 13, a lower terminal block 14 and an EMC hook 15. The upper terminal block 13 is provided with an upper plastic clamping piece, and the upper plastic clamping piece is fixed with several terminals, and the lower terminal block 14 is provided with a lower plastic clamping piece. piece, and the lower plastic clamping piece is fixed with a number of terminals. The lower terminal row 14, the upper terminal row 13 and the lower terminal row 14 are assembled up and down, the EMC hook 15 is assembled in the middle of the upper termi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com