Technology for machining biological functioning experimental equipment shell

A technology of experimental equipment and processing technology, which is applied in the field of biological function experimental shell manufacturing, can solve the problems of high cost, unsuitable for small batch processing and production, and long processing cycle, and achieve the effect of low cost, short processing cycle and firm structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

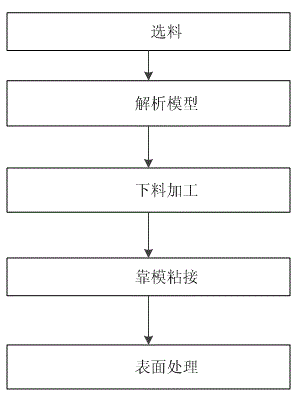

[0023] In the first embodiment, the shell processing technology of biological function experiment equipment is provided, please refer to figure 1 , the process includes:

[0024] (1) Material selection: select the type of material according to the preset conditions, which include but are not limited to: equipment type, equipment use, equipment use environment, equipment shape, and use objects;

[0025] (2) Analytical model: decompose the input equipment model in units of features and surfaces;

[0026] ⑶Blanking processing: Cut the raw materials into small pieces according to the results of the decomposition of the equipment model, and then perform preset processing on each small piece. The preset processing includes but is not limited to: heating bending, blistering, engraving, opening, Hook slot;

[0027] ⑷Profile bonding: Assemble and divide the processed small pieces according to the external dimensions of the equipment, bond them with special adhesives corresponding to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com