An automatic chicken gizzard incision skinning machine

A peeling machine and chicken gizzard technology, which is applied in metal processing, slaughtering, poultry processing, etc., can solve the problems of affecting processing efficiency, increasing the peeling process, and not being able to automatically squeeze the skin, so as to improve processing efficiency and reduce feeding congestion. , Realize the effect of automatic peeling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

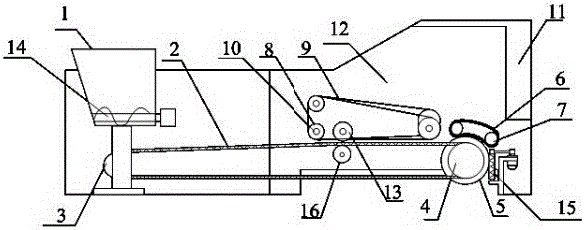

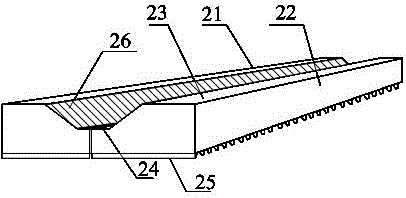

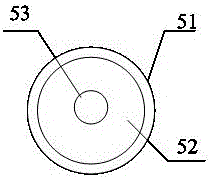

[0030] as attached figure 1 to attach Figure 7 shown

[0031] The invention provides an automatic chicken gizzard incision skinning machine, which includes a hopper 1, a horizontal transmission device 2, a start pulley 3, a terminal pulley 4, a gizzard turning wheel 5, a gizzard turning belt 6, a transmission gear 7, a pulley 8, an extrusion Belt 9, transmission shaft 10, transmission device 11, frame 12, gizzard cutting cutter head 13, stirring device 14, peeling device 15 and supporting wheel 16, and the described hopper 1 is installed on the upper left end of the horizontal conveying device 2; The horizontal transmission device 2 is installed on the top of the starting pulley 3 and the terminal pulley 4, and two of the starting pulley 3 or the terminal pulley 4 are used; the turning over wheel 5 is installed in the middle of the terminal pulley 4; Described turning over gizzard belt 6 is installed on the top of turning over gizzard wheel 5 by transmission gear 7; Describ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com