Hot-rolled wheel and manufacturing method

A manufacturing method and technology of wheels, which are applied to wheels, wheels characterized by rail running parts, vehicle parts, etc., can solve the problems of coarse internal organization, environmental pollution, slag inclusion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

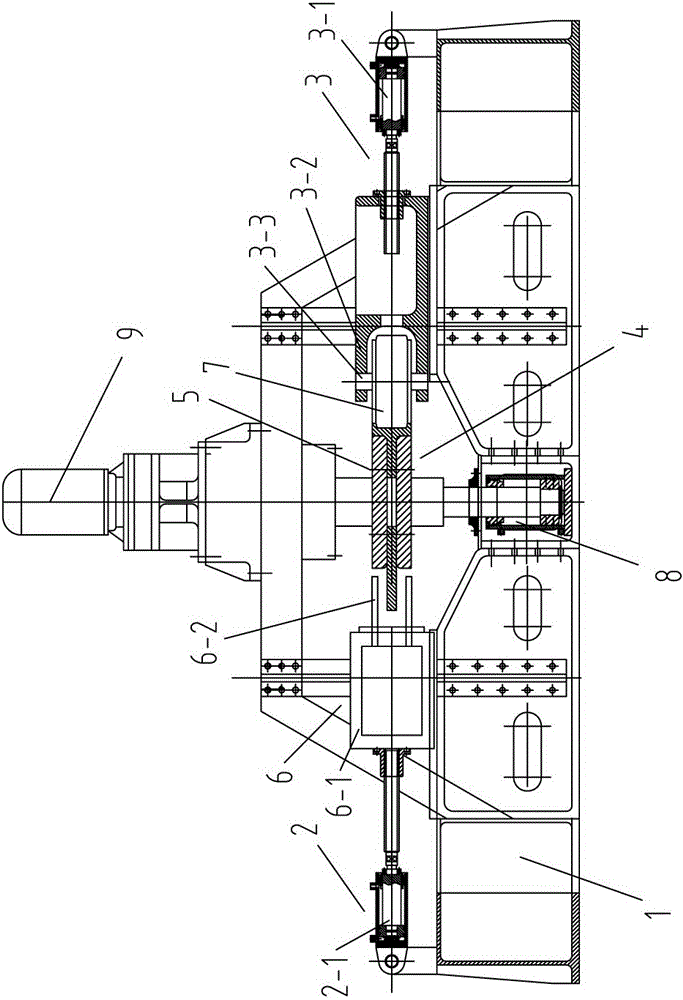

[0021] The present invention is described in further detail below in conjunction with the embodiment that accompanying drawing provides.

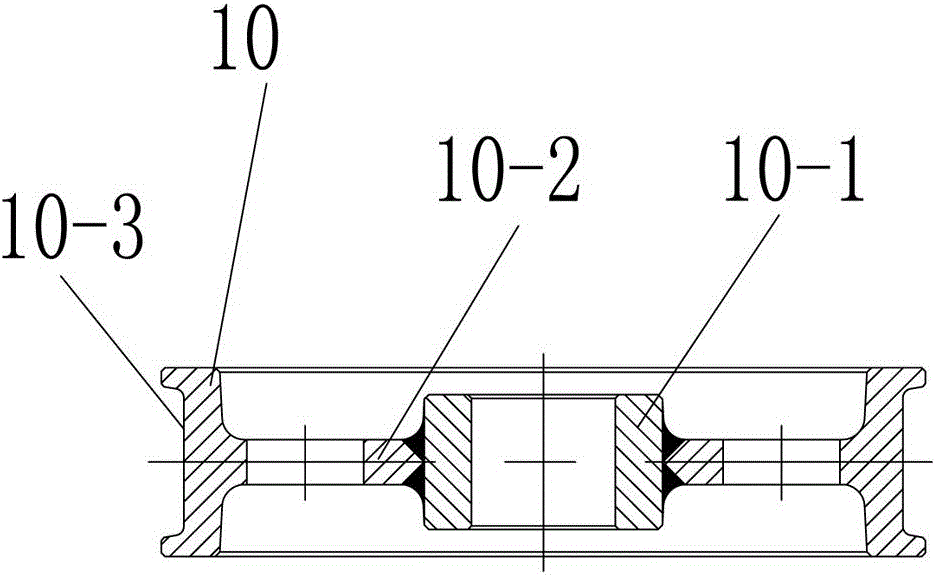

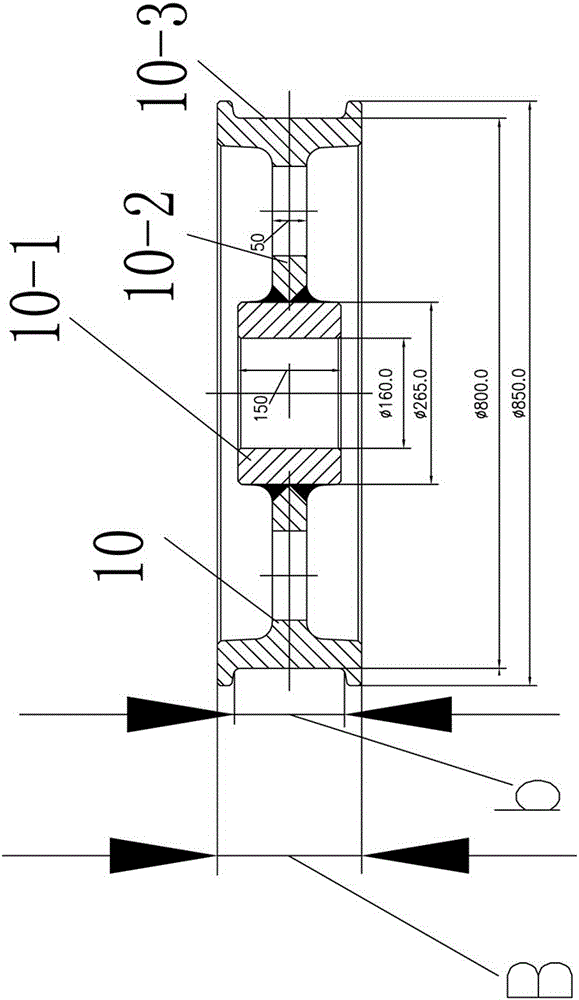

[0022] see figure 1 As shown, a hot-rolled wheel includes a hub 10-1, a spoke 10-2 and a tread 10-3, the spoke 10-2 and the tread 10-3 are integral structures, and the hub 10-1 and the spoke 10- 2 are welded together.

[0023] A method for manufacturing the above-mentioned hot-rolled wheel, which sequentially includes a blank 10→rough machining→heat treatment→finishing forming, the blank 10 includes a hub 10-1, a spoke 10-2 and a tread 10-3, and the spoke 10 -2 and the tread surface 10-3 are integral structures, and the hub 10-1 and the spokes 10-2 are welded as a whole. Manufactured using the following process:

[0024] ①Blanking: Select a steel plate with the same thickness as the spoke 10-2, and cut the central hub hole and the outer ring-shaped sheet blank according to the size of the blank drawing that meets the technical requiremen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com