A kind of wooden structure load-bearing thermal insulation wallboard

A technology of thermal insulation wall panels and wooden structures, which is applied in building components, building structures, buildings, etc., can solve the problems of low automation rate of workshop components, low assembly rate of thermal insulation wall panels, poor durability, etc., and achieve assembly speed The effect of fast, light weight and high bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

[0024] In the embodiment of the present invention, the load-bearing thermal insulation wallboard of the wooden structure is arranged on the concrete foundation wall section to bear the load of the wallboard at the upper end;

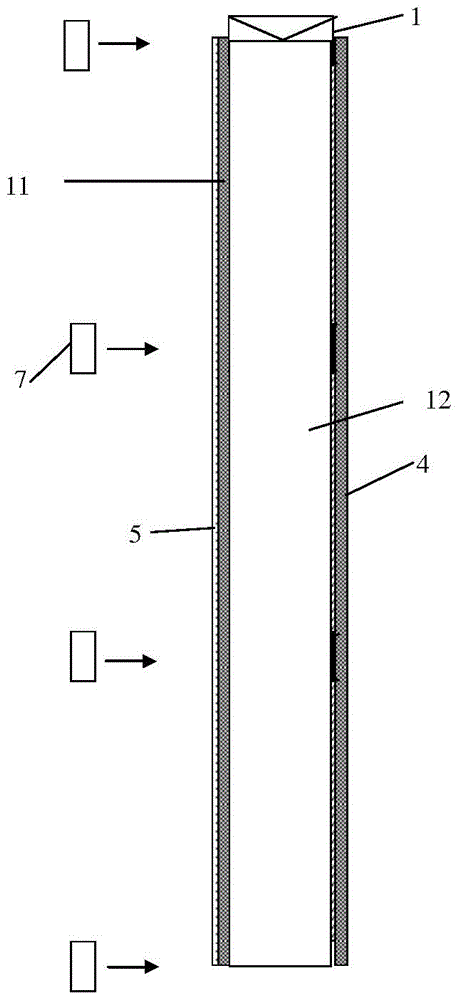

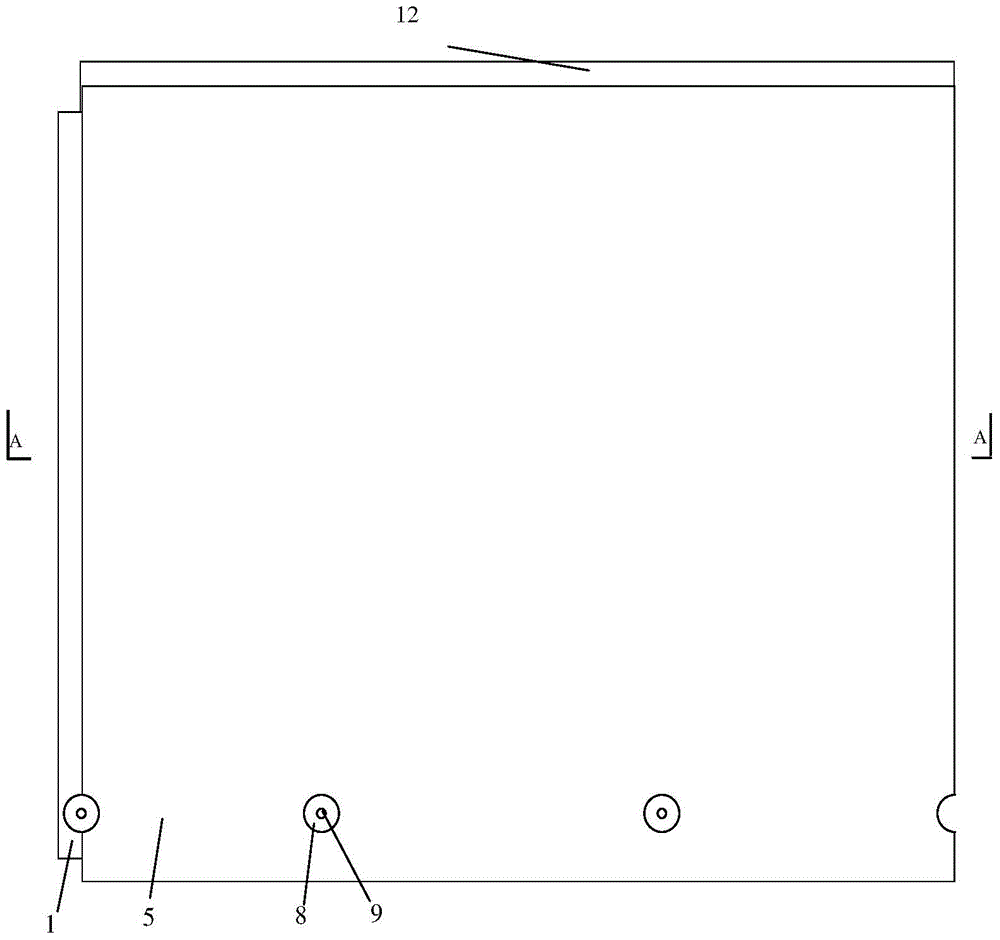

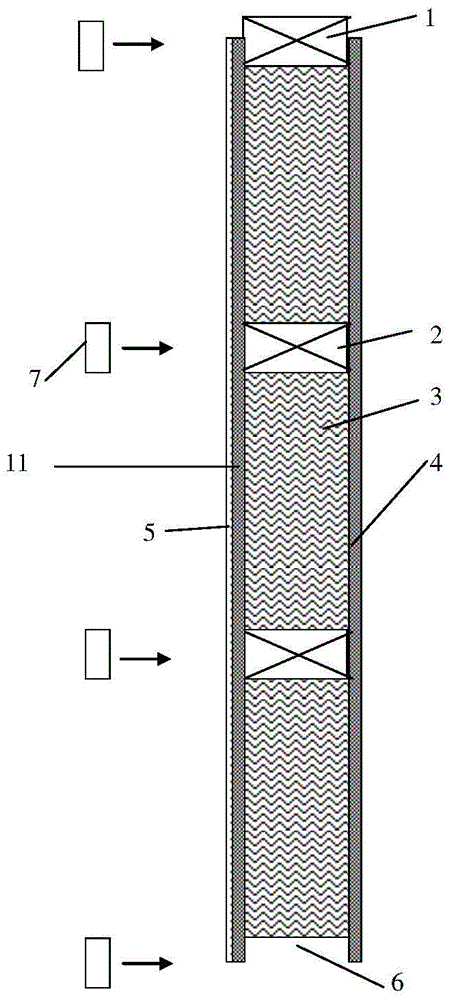

[0025] In the embodiment of the present invention, such as figure 1 , figure 2 and image 3 As shown, a wooden structure load-bearing thermal insulation wallboard, including wooden beams 12, interface load-bearing wooden columns 1, internal load-bearing wooden columns 2, inner recycled boards 4, outer recycled boards 11 and waterproof and breathable membranes 5; wherein,

[0026] The inner recycled board 4 and the outer recycled board 11 are placed parallel to each other; between the inner recycled board 4 and the outer recycled board 11, there are 1 to 10 built-in load-bearing wooden columns 2, and the adjacent built-in load-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com