Light weight mobile toilet panel manufacturing method

A production method and lightweight technology, applied in the field of mobile toilet panel production, can solve the problems of high production and raw material costs, slowness, difficult handling and installation, etc., and achieve the effects of increasing production capacity, reducing weight, and easy handling and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0035] Usually according to the present invention, such as Figure 1 to Figure 7 As shown, it goes through the procedures of blow molding and cutting in sequence, and can complete the production of lightweight mobile toilet panels, among which:

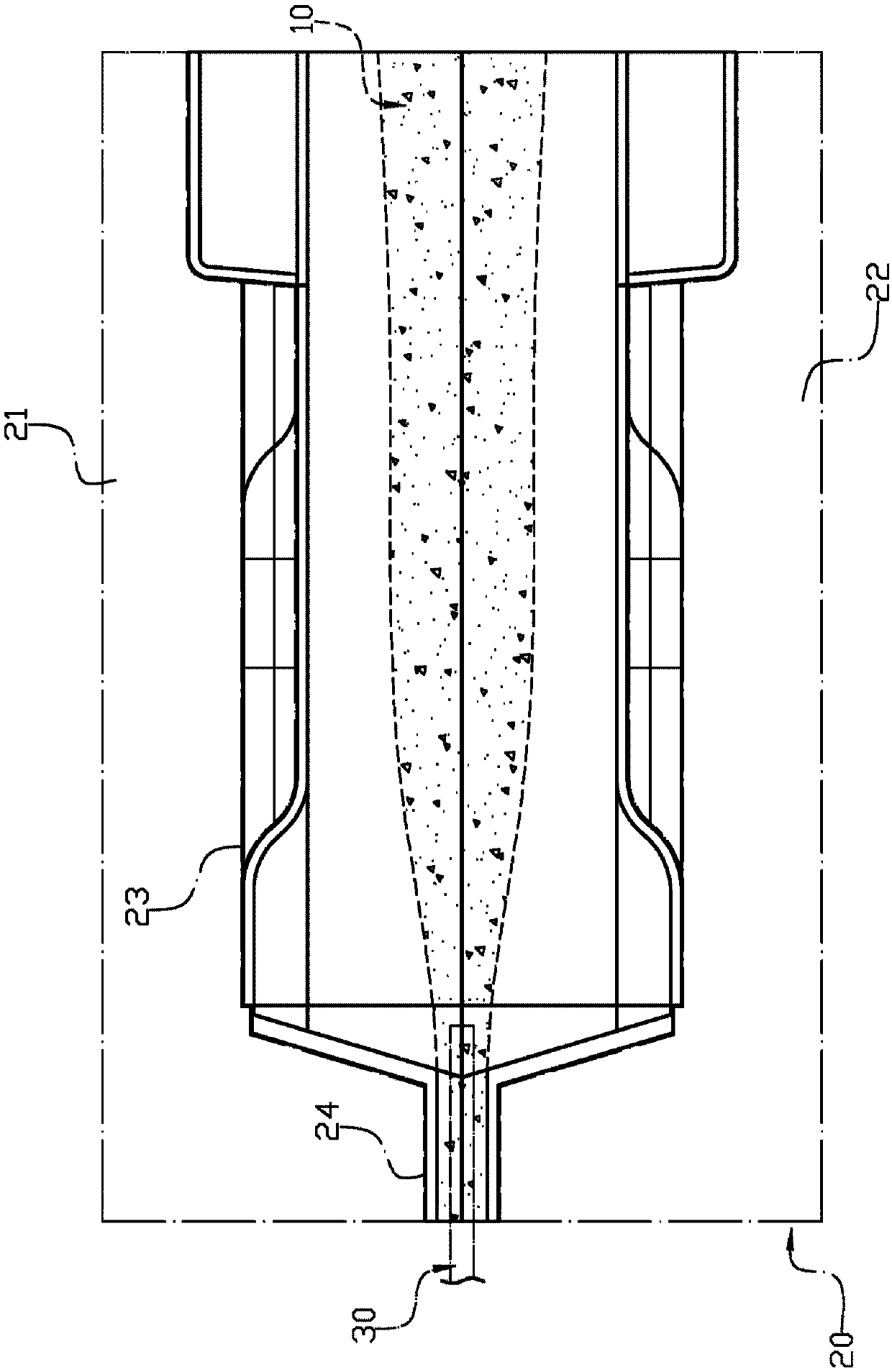

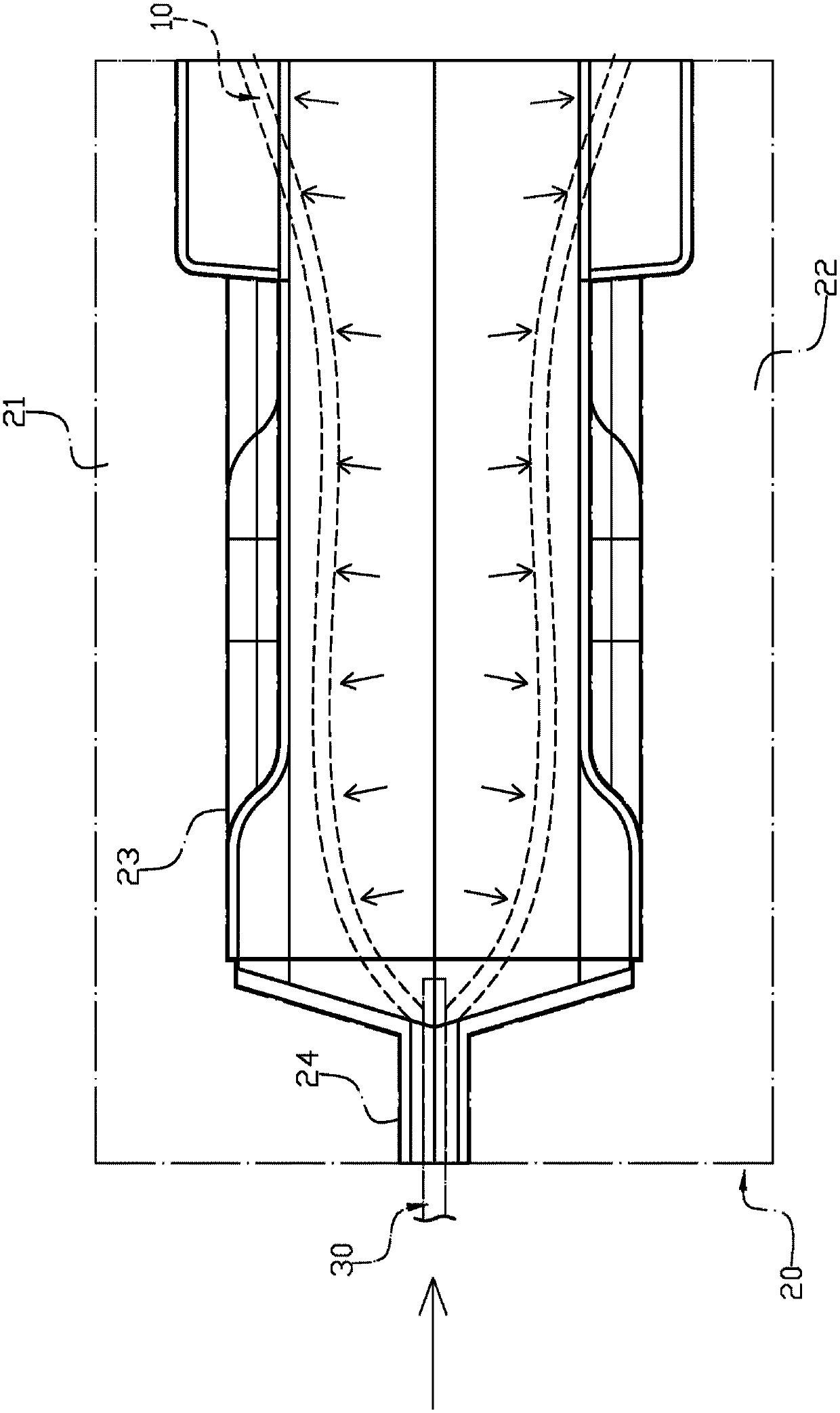

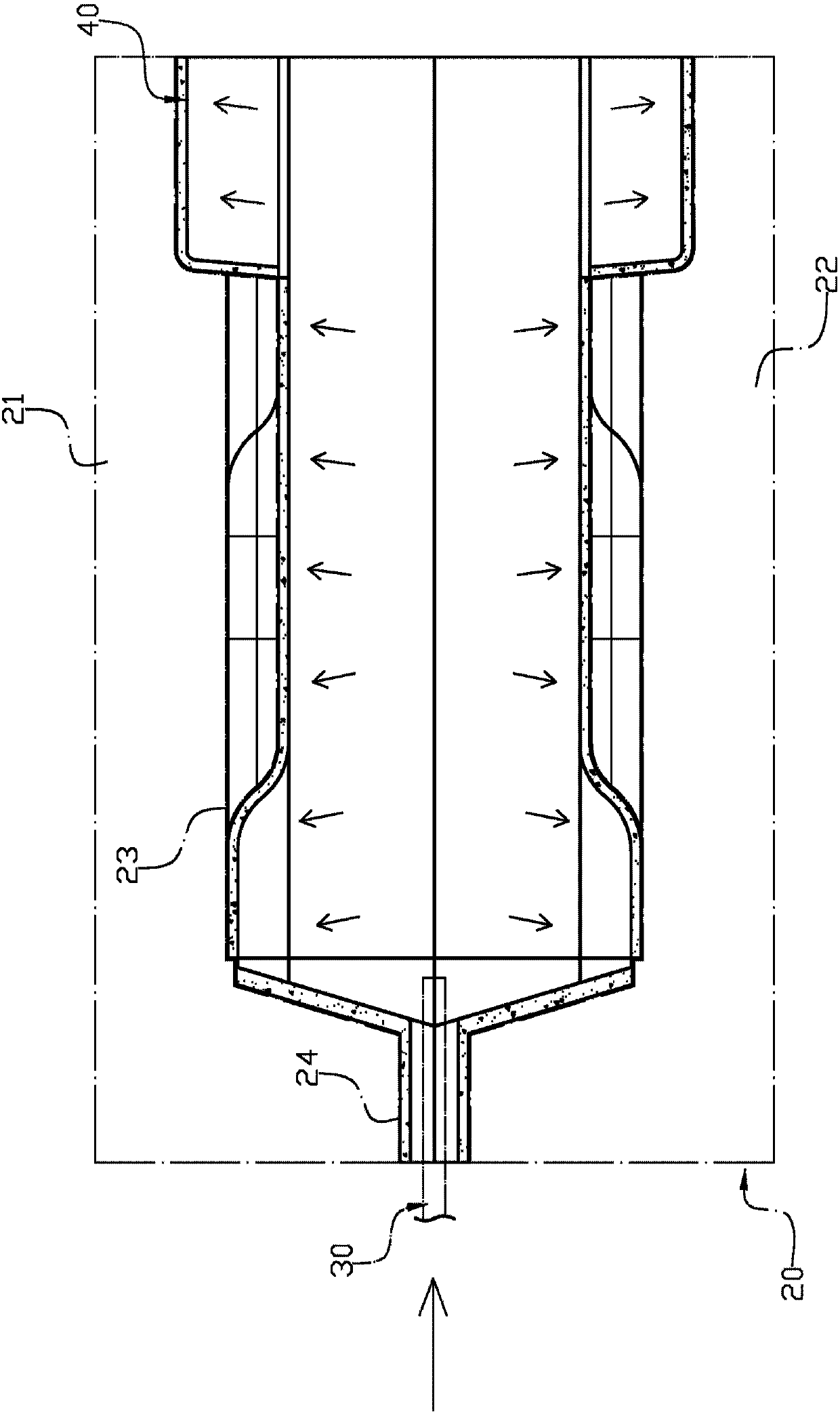

[0036] Blow molding (such as Figure 1 to Figure 3 As shown), the plastic material 10 is melted by a hollow molding machine, and then placed in the molding die 20. The molding die 20 has an upper die 21 and a lower die 22, and a mold cavity 23 is provided inside. The upper die 21, The clamping part of the lower mold 22 has a blowing hole 24 extending to the position of the mold cavity 23, so that the hollow molding machine can penetrate the mold cavity 23 with a blowing pipe 30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com