Adjustable stator blade linkage adjusting device

A technology of stator vanes and adjustment devices, applied in machine/engine, pump control, non-variable-capacity pumps, etc., can solve the problems of unable to achieve variable angle adjustment, affecting test results, affecting test cycles, etc., to avoid the angle that cannot be arbitrarily Adjust, operate efficiently, avoid the effect of complicated operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Reference will now be made in detail to the exemplary embodiments, examples of which are illustrated in the accompanying drawings. When the following description refers to the accompanying drawings, the same numerals in different drawings refer to the same or similar elements unless otherwise indicated.

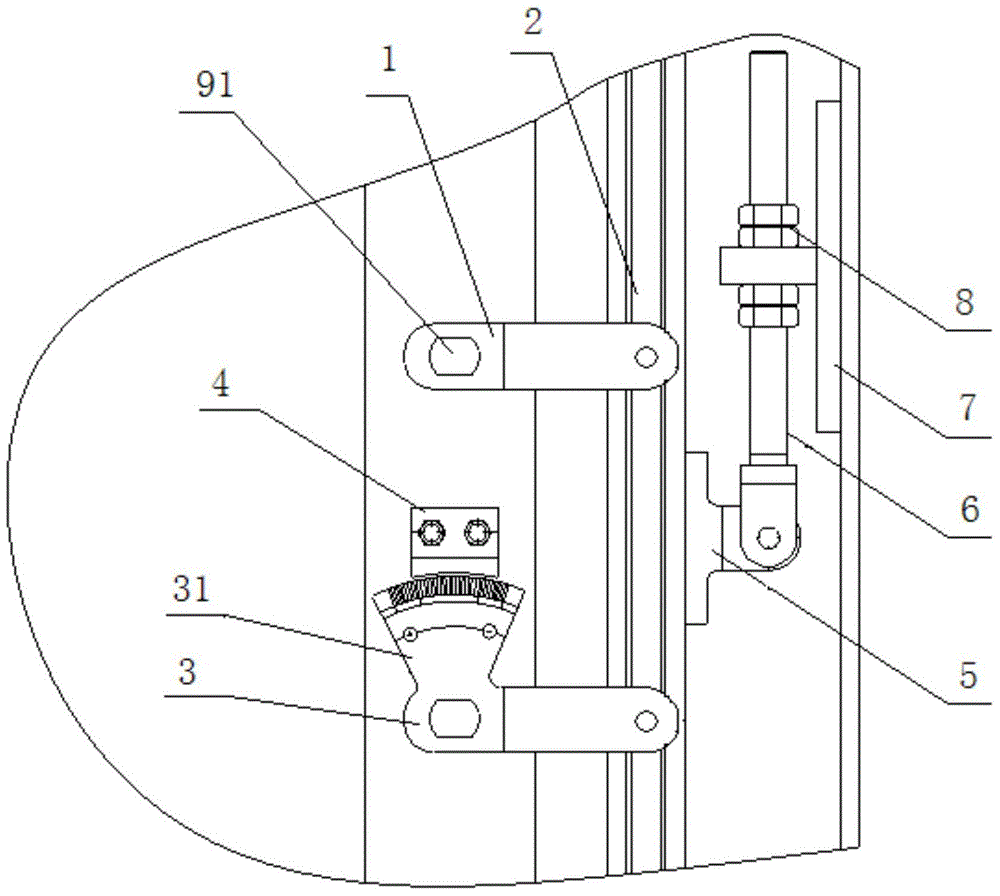

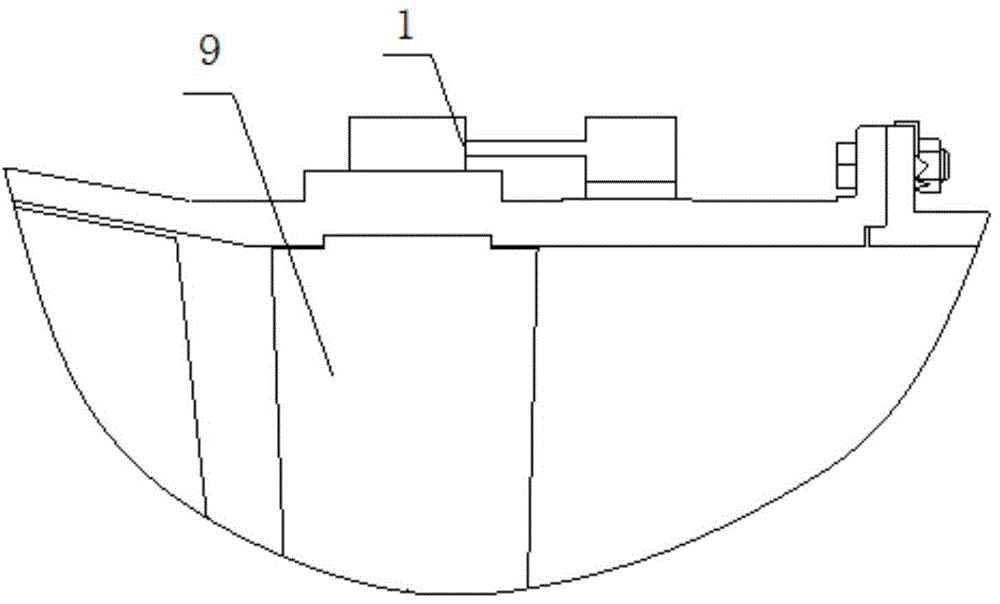

[0027] figure 1 It is a structural schematic diagram of the adjustable stator vane linkage adjustment device of the present invention, in which the compressor is not fully shown. figure 2 It is a structural schematic diagram of another viewing angle of the adjustable stator blade linkage adjustment device of the present invention, based on figure 1 As a standard of view, the schematic is viewed from the left, although the figure 1 All components in figure 2 It is not completely shown in the figure, but it does not affect the understanding of the technical solutions of the present application by those of ordinary skill in the art.

[0028] Such as figure 1 with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com