Vibration-absorbing mount for gearbox based on hydraulic mount

A technology of hydraulic mount and gear box, applied in the direction of spring/shock absorber, vibration suppression adjustment, non-rotation vibration suppression, etc. Consumption and other problems, to achieve the effect of improving the effect of vibration reduction and isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

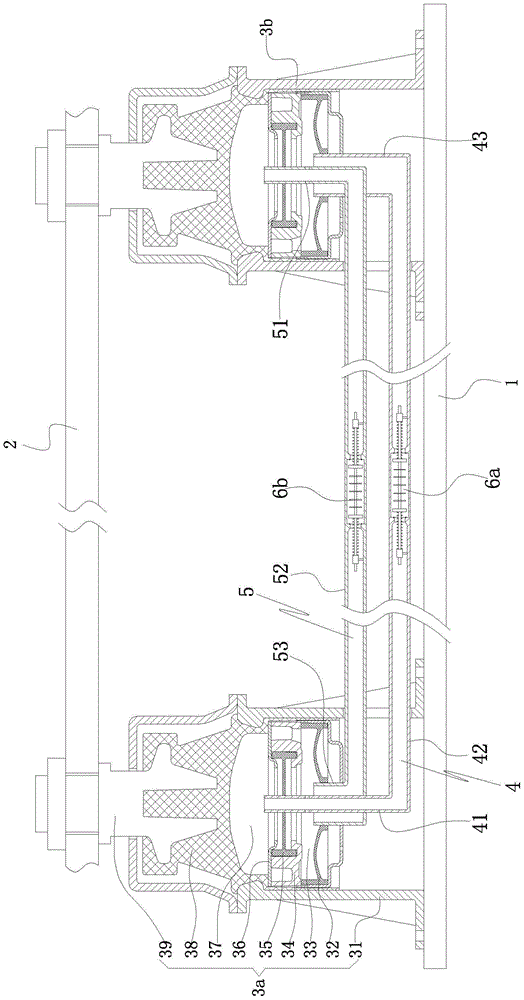

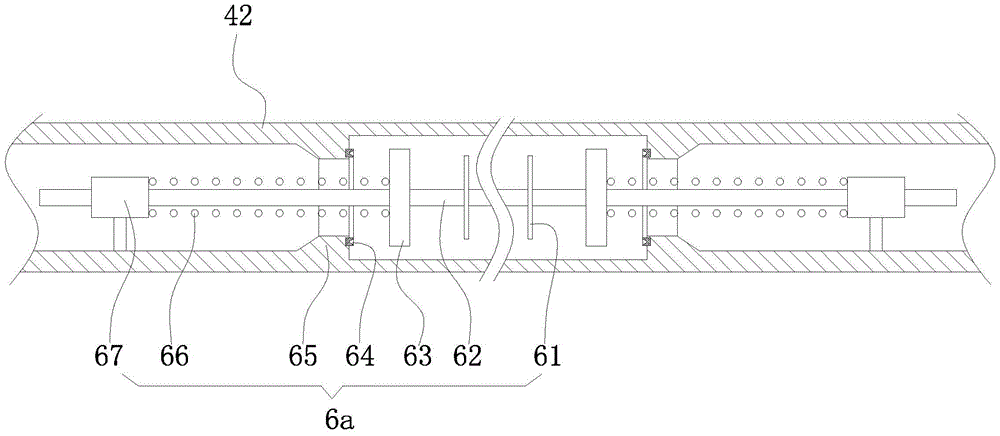

[0026] Such as figure 1 As shown, a vibration-damping installation frame for a gearbox based on a hydraulic mount includes a bottom frame 1, a top frame 2 for installing a gearbox, and several hydraulic mounts arranged on the bottom frame for supporting the top frame. The hydraulic mounts in this embodiment include a left front hydraulic mount 3a, a right front hydraulic mount 3b, a left rear hydraulic mount and a right rear hydraulic mount. The left front, right front, left rear and right rear four hydraulic suspensions are located between the bottom frame and the top frame. The base frame is square. The left front, right front, left rear and right rear four hydraulic mounts are distributed at the four top corners of the chassis. The hydraulic mount in this embodiment is prior art. Each hydraulic mount includes a base 31, a rubber main spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com