Roll coating type oiling device

An oiling device and roller coating technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of separation, difficult molds and forming plates, etc., and achieve the effect of ingenious structure and uniform oiling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

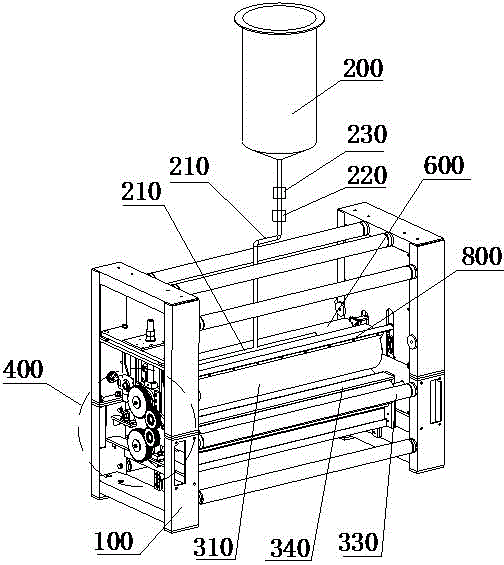

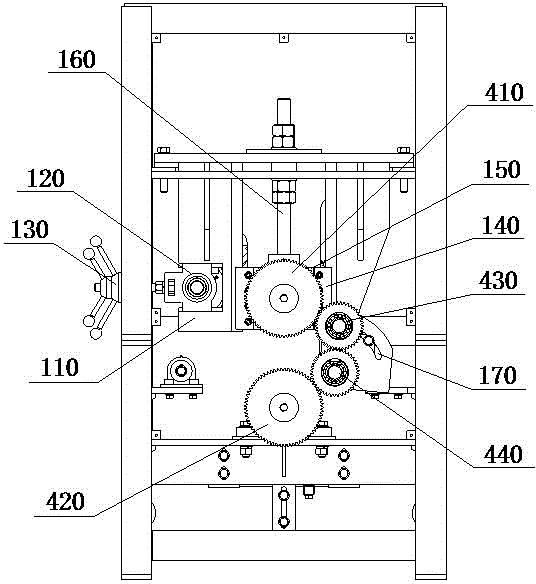

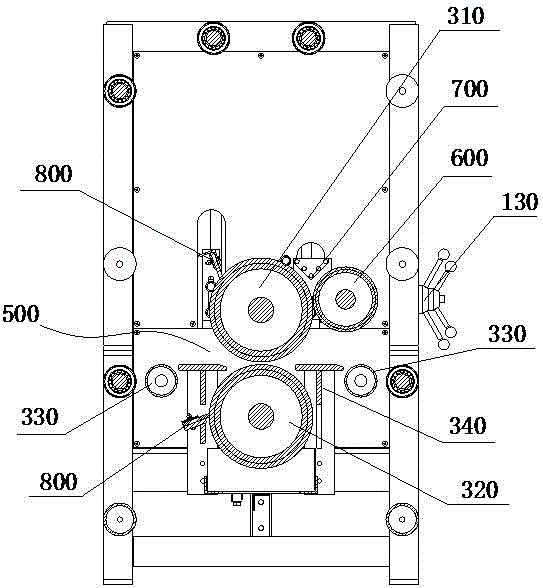

[0017] The invention discloses a rolling coating type automatic oiling device, such as figure 1 with image 3 As shown, it includes a bracket 100 , an oil barrel 200 and an oil delivery pipe 210 connected to the oil barrel 200 , and the oil delivery pipe 210 is provided with a switch valve 220 . A first transport roller 310 and a second transport roller 320 are arranged in parallel on the support 100, and the two transport rollers are arranged up and down (see image 3 ), connected by a gear set 400, and a plurality of support rollers 330 are arranged in parallel on both sides of the middle of the two transport rollers (see image 3 ), forming a mold transportation path 500 . In practical applications, in order to improve the uniformi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com