Hydraulic drawing pad of a drawing press and method of operating a hydraulic drawing pad

A hydraulic deep drawing and press technology, which is applied to fluid pressure actuating devices, mechanical equipment, servo meter circuits, etc., can solve the problems of expensive hydraulic deep drawing pads and inability to generate metal sheet holding force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

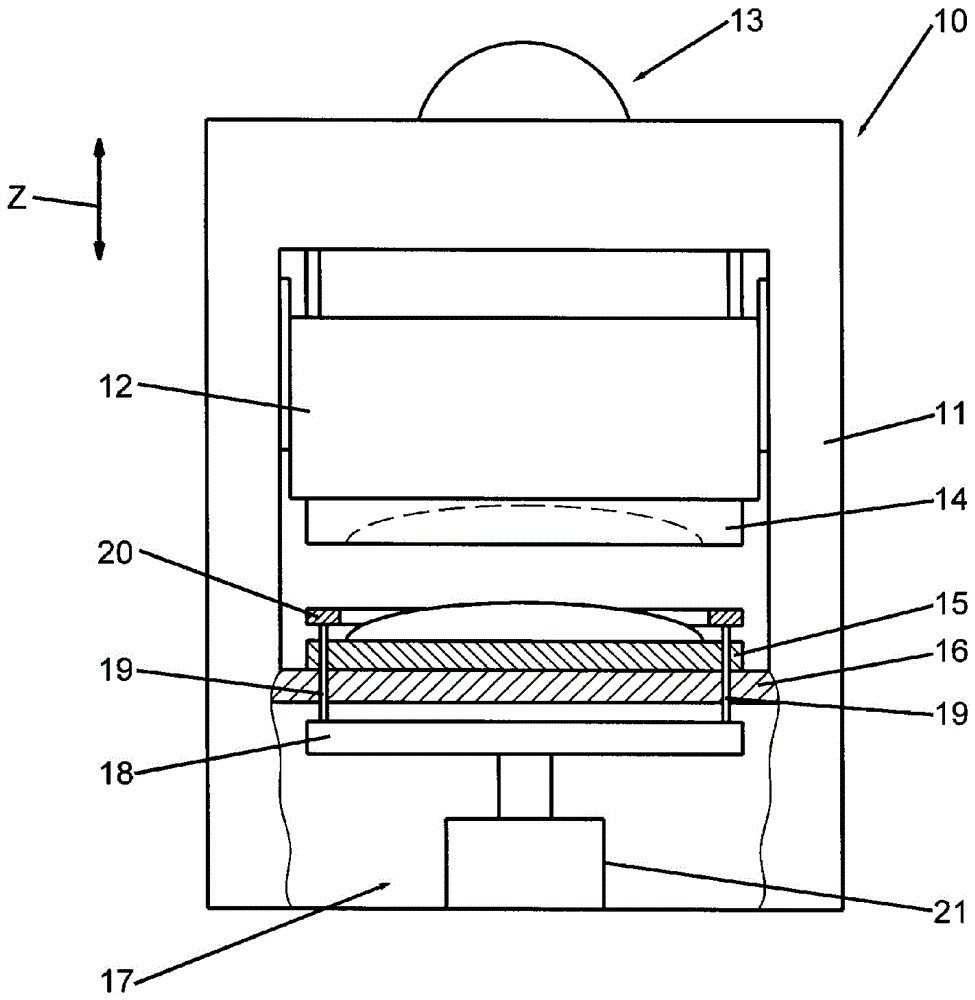

[0036] figure 1 is a schematic illustration of a drawing press 10 with a press frame 11 . The ram 12 is arranged on the press frame 11 so as to be movable in the working direction Z, for example in the vertical direction. A press drive 13 is arranged to move the ram 12 . A first tool 14 is arranged on the ram 12 . A second tool 15 is supported at a distance from the first tool by the press frame 11 , for example by means of a press table 16 .

[0037] Furthermore, the drawing press 10 includes a hydraulic drawing pad 17 . The hydraulic drawing pad 17 is located on the side of the second tool 15 facing away from the first tool 14 , ie, according to the example, under the press table 16 . The floating plate 18 is associated with the hydraulic drawing pad 17 . Arranged on the floating plate 18 is a pressure rod 19 which extends from the floating plate 18 to the second tool 15 . According to the example, the pressing rod 19 extends through the press table 16 and through and / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com