Equipment for controlling accurate positioning of pipe column bracket

A technology for precise positioning and control of tubes, applied in metal processing equipment, manufacturing tools, metal processing, etc., can solve problems such as poor precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

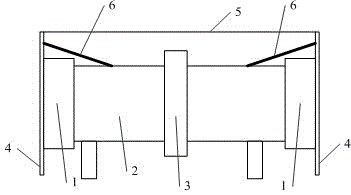

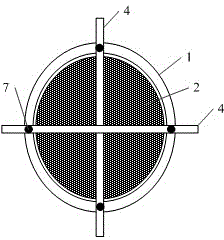

[0025] In the embodiment, a device for controlling the precise positioning of the corbel of the pipe string is provided, please refer to Figure 1-Figure 2 , The equipment includes:

[0026] Two cylinders 1 and two inspection structures, the two cylinders 1 are respectively sleeved on the outer surfaces of both ends of the pipe string 2 to be tested, and the inner diameter of the cylinder 1 matches the outer diameter of the pipe string 2 , The center line of the cylinder 1 coincides with the center line of the pipe string 2, the cylinder 1 is provided with a screw hole, the inspection structure includes: two inspection brackets 4, the two inspection brackets 4 The inspection structure is vertically connected to form the inspection structure, the inspection structure is in the shape of a cross, the middle of the two inspection supports 4 overlap, the two inspection structures are connected with a tension wire 5, and the inspection support 4 is provided with Screw holes, fixing sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com