A method for forming a motor casing

A molding method and casing technology, applied in the field of motor parts, can solve problems such as affecting product performance, low work efficiency, complex process, etc., and achieve the effects of improving workpiece accuracy, reducing positioning work, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

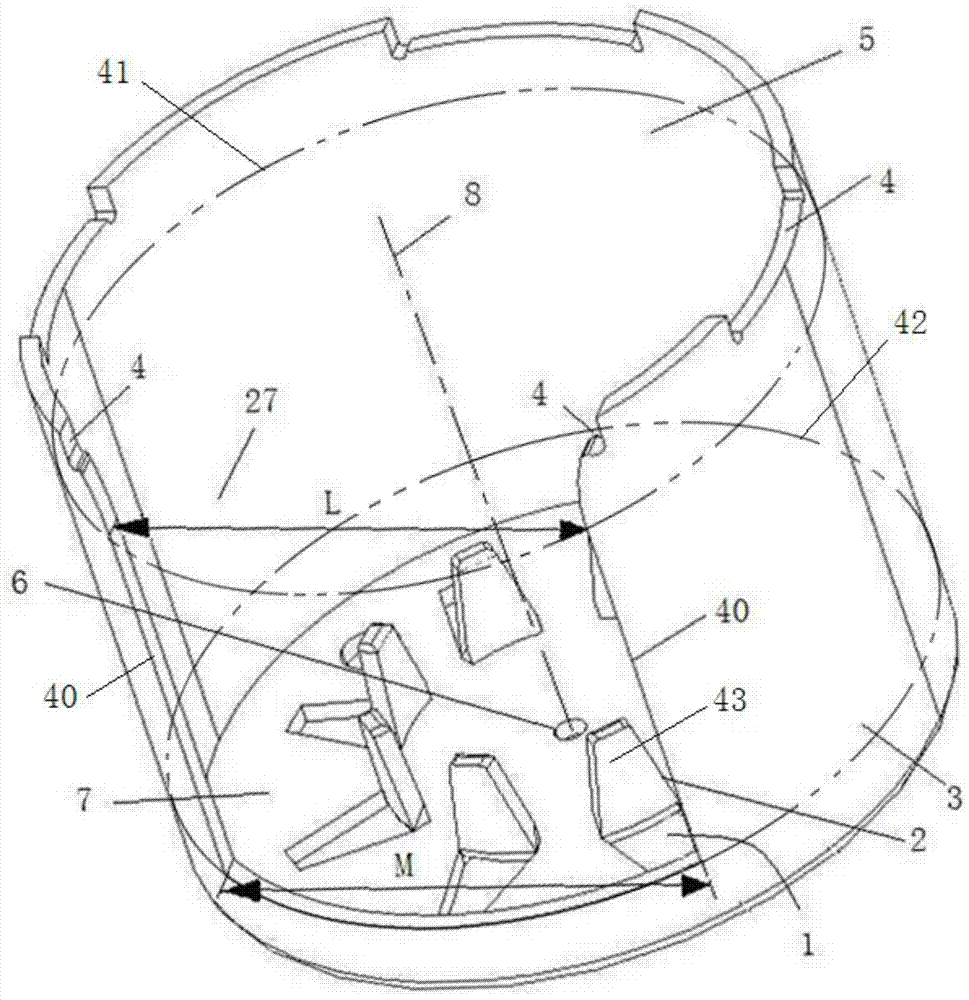

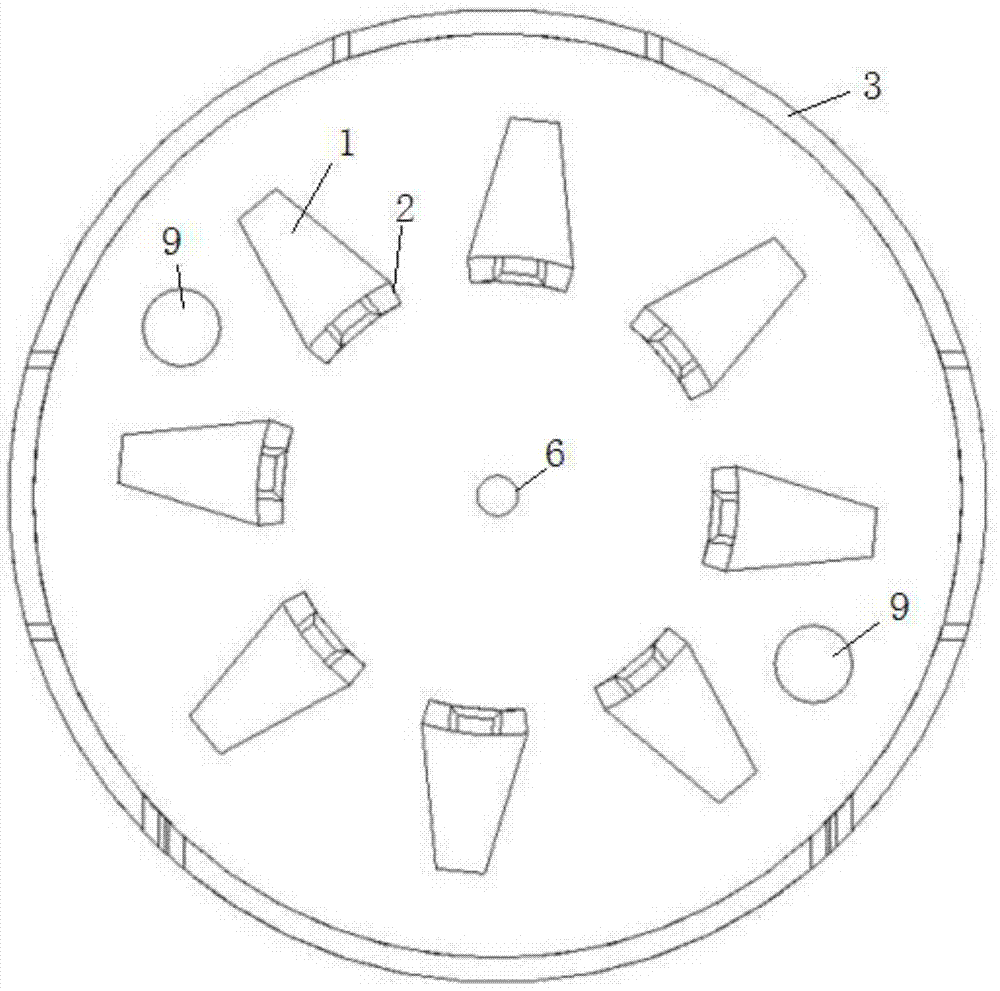

[0033] Depend on Figure 1-Figure 2 A motor casing shown includes a cylindrical shell surrounded by an annular side wall 3 and an end plate 7, the annular side wall 3 extends up and down, the end plate 7 is arranged at the bottom end of the annular side wall 3, and the shell The top end of the body is the opening end 5, that is, the top end of the annular side wall 3 is the opening end 5 of the housing, and the top surface of the annular side wall 3 is the top surface of the housing. The annular side wall 3 and the end plate 7 are of an integral structure.

[0034] The top of the annular side wall 3 is provided with a side cutout 27 and a cover plate installation groove 4 for installing the cover plate. The side cutout 27 and the cover plate installation groove 4 are radially transparent, and the notch of the cover plate installation groove 4 is upward. The side slit 27 extends downward from the top of the annular side wall 3 to the bottom of the annular side wall 3. The side...

Embodiment 2

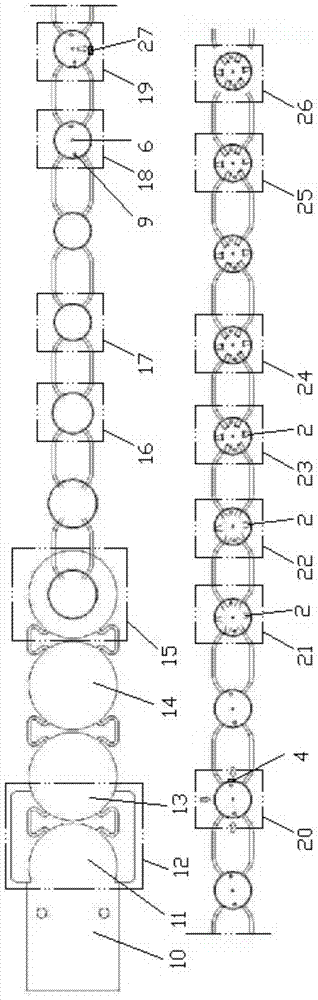

[0040] image 3 — Figure 11 It is a molding method of the motor casing described in Embodiment 1. The material strip 10 is walked in the continuous mold of the motor casing. Carry out the operation that comprises following operation to strip 10 on each station of continuous mould:

[0041] (1), the strip 10 cuts out the front side 13 with the front circular arc edge, the rear side 11 with the rear circular arc edge and the connecting belt on the first station 12, the rear side 11 and the rear side The material belt and the remaining material are thrown together as a whole, the front arc edge and the rear arc edge are set backwards, and when the front arc edge and the rear arc edge are connected, a full circle can be formed, and the connecting belt is connected between the front, Between the rear side parts 13 and 11, there are two connection belts connected between the adjacent front and rear side parts 13 and 11. The two connection belts are respectively located on the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com