A method for manufacturing a thin-walled wear-resistant shaft sleeve

A manufacturing method and a shaft sleeve technology, which are applied in the field of mechanical processing, can solve problems such as inner wall deformation and shaft sleeve out-of-roundness, and achieve the effect of avoiding out-of-roundness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

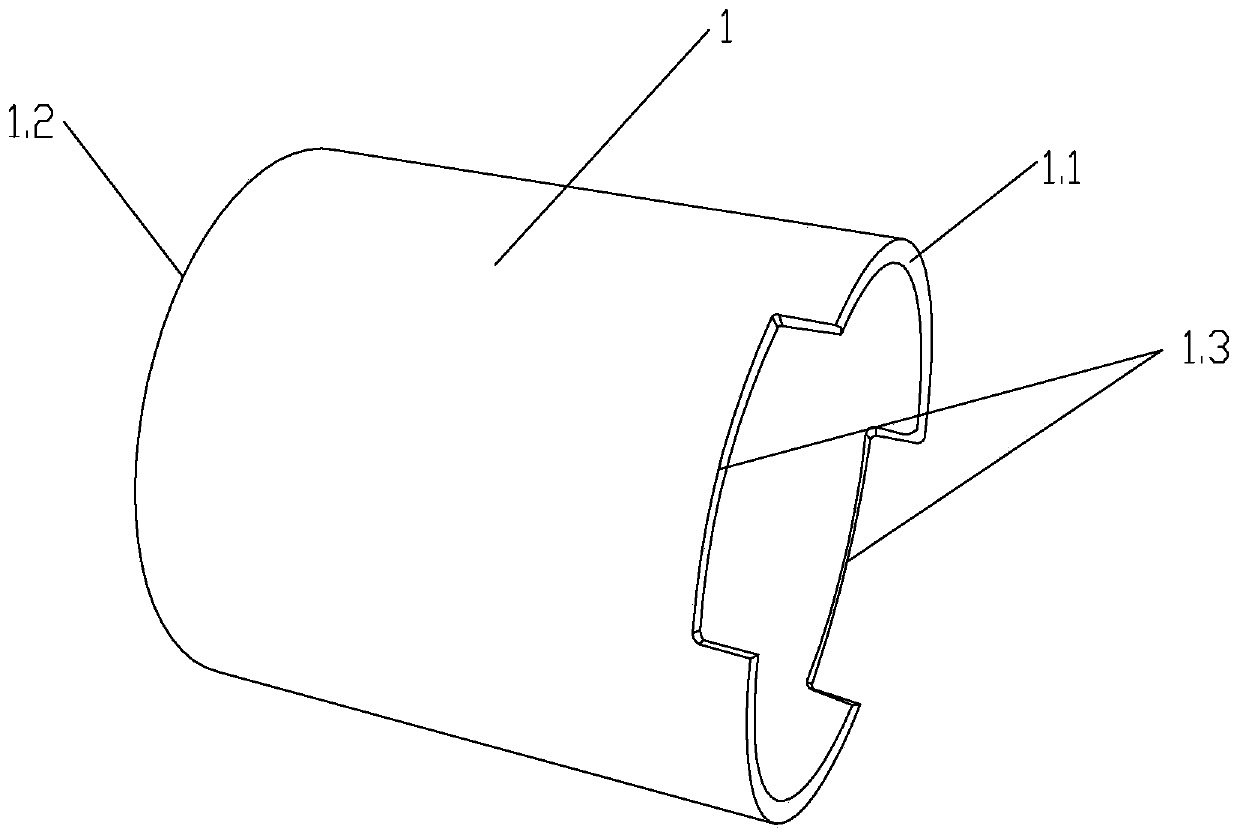

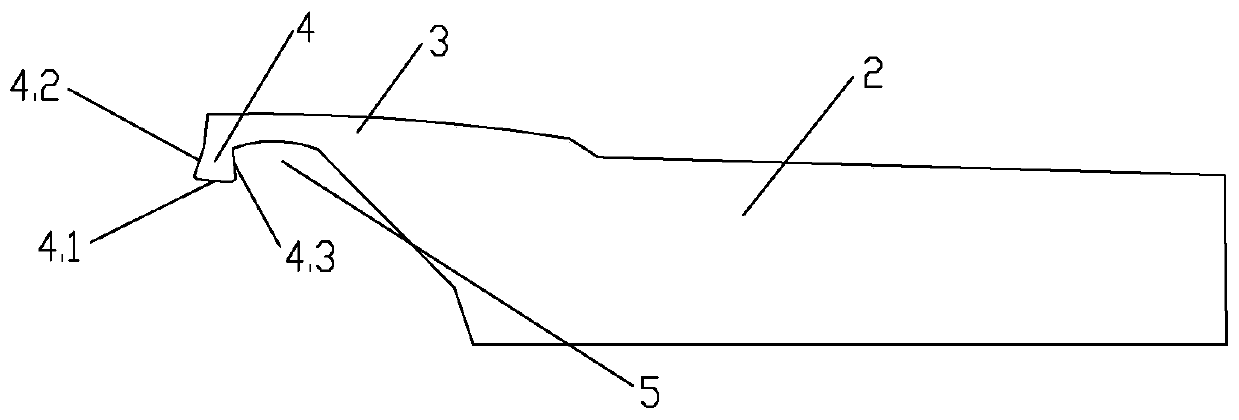

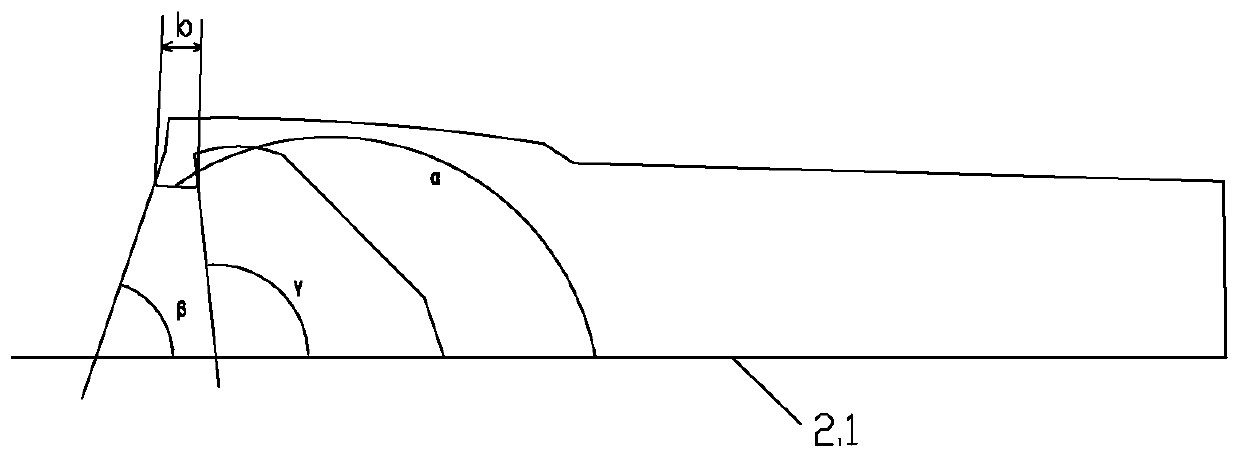

[0032] The present invention will be further described below in conjunction with accompanying drawing.

[0033] Such as Figure 1-8 As shown, the manufacturing method of the thin-walled wear-resistant bushing of the present invention includes the following steps: the first step of heat treatment: put the blank of the bushing 1 into the furnace, start to heat up to 700 ° C within 30 minutes, keep it warm for 1 hour, and then perform annealing, The annealing temperature is 300°C, and the furnace is released at room temperature; through this step of stress relief annealing, the metal undergoes internal local plastic deformation under the action of a certain temperature, and when the stress exceeds the yield strength of the material at this temperature, or a local relaxation process, when the stress When it is less than the yield strength of the material at this temperature, the residual stress is relaxed to achieve the purpose of elimination. After holding for a period of time, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com