A kind of truss lattice sandwich structure

A structure and truss-like technology, which is applied in the field of truss-like lattice sandwich structures, can solve problems such as complex structures, safety, and poor shear performance, and achieve improved shear performance, novel and reasonable structural design, and excellent mechanical properties. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

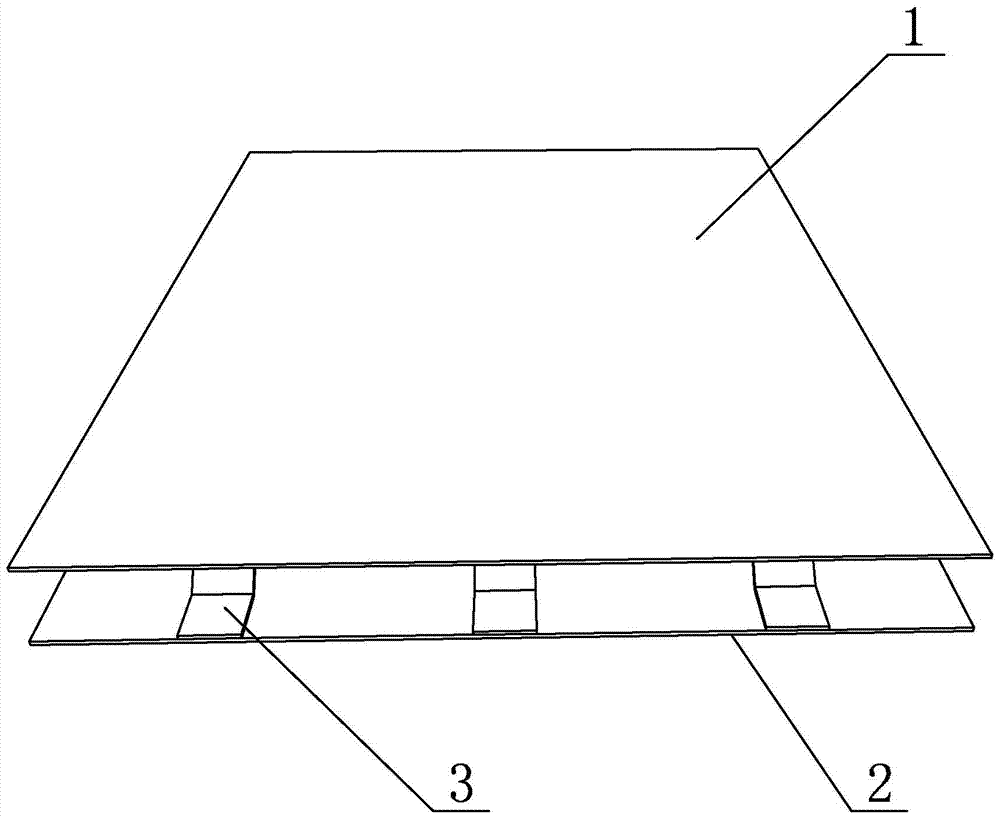

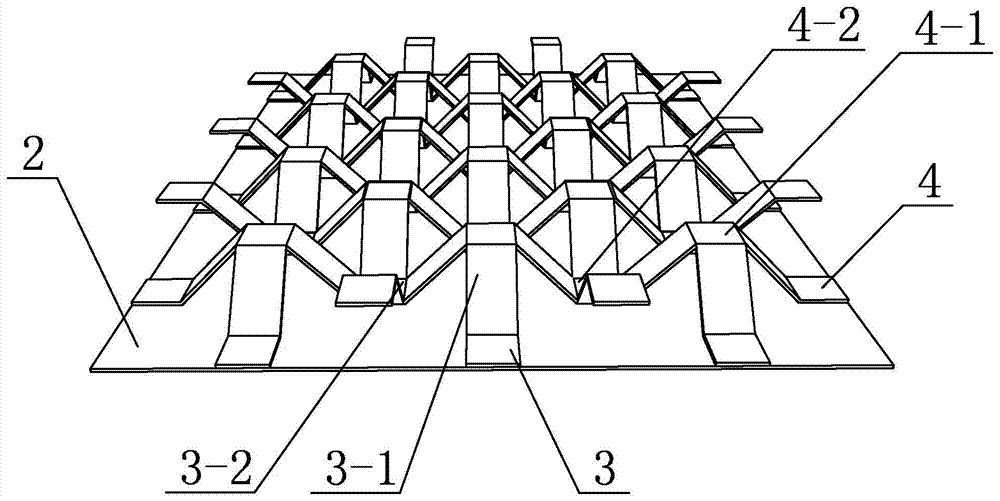

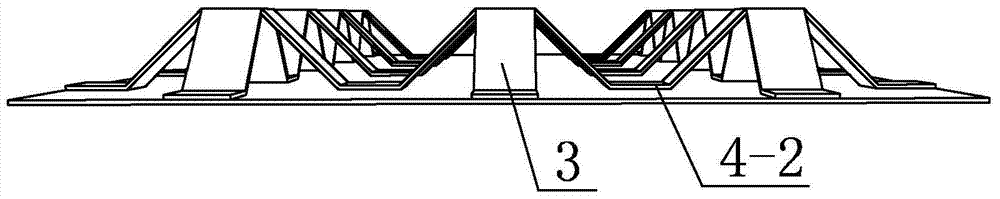

[0031] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 7 , Figure 8 , Figure 9 , Figure 13 and Figure 15 Describe this embodiment, this embodiment comprises upper panel 1, lower panel 2, a plurality of first splicing laths 3 and a plurality of second splicing laths 4, each first splicing laths 3 is uniformly processed along its length direction A plurality of first convex curved surfaces 3-1 and a plurality of first concave curved surfaces 3-2, the first convex curved surfaces 3-1 and the first concave curved surfaces 3-2 are arranged alternately and have the same shape; Its length direction is uniformly processed with a plurality of second convex curved surfaces 4-1 and a plurality of second concave curved surfaces 4-2, the second convex curved surfaces 4-1 and the second concave curved surfaces 4-2 are arranged alternately and have the same shape, and the plurality of second convex curved surfaces 4-1 and second concave curved su...

specific Embodiment approach 2

[0032] Specific implementation mode two: combination figure 1 and image 3 Describe this embodiment, in this embodiment, a plurality of first splicing slats 3 are evenly distributed on the upper end surface of the lower panel 2 along the length direction of the lower panel 2, and a plurality of second splicing slats 4 are evenly distributed along the width direction of the lower panel 2 On the upper end face of the lower panel 2. In this embodiment, the orientations of the multiple first splicing slats 3 and the orientations of the multiple second splicing slats 4 are perpendicular to the edge of the lower panel 2, and this structure is called a 90° symmetrical truss point. Sandwich structure. The connection relationship between the plurality of first splicing strips 3 and the plurality of second splicing strips 4 and the upper panel 1 is the same as that of the lower panel 2 . Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0033] Specific implementation mode three: combination Figure 7 and Figure 9Describe this embodiment, in this embodiment, a plurality of first splicing slats 3 are evenly distributed on the upper end surface of the lower panel 2 along a diagonal direction of the lower panel 2, and a plurality of second splicing slats 4 are arranged along the direction of the lower panel 2. The direction of the other diagonal line is evenly distributed on the upper end surface of the lower panel 2. In this embodiment, the directions of multiple first spliced slats 3 and multiple second spliced slats 4 are parallel to the diagonals of the lower panel 2, and this structure is called 45° positive symmetry. Truss lattice sandwich structure. The connection relationship between the plurality of first splicing strips 3 and the plurality of second splicing strips 4 and the upper panel 1 is the same as that of the lower panel 2 . Other components and connections are the same as those in the fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com