Automobile tubular frame

A technology for automobiles and frames, applied in load-bearing body structures, vehicle components, upper structures, etc., can solve the problems of low degree of customization, high cost of automobile frames, and difficulties in automobile modification, etc., to meet the needs of personalized customization Demand, low production cost, large effect of random modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

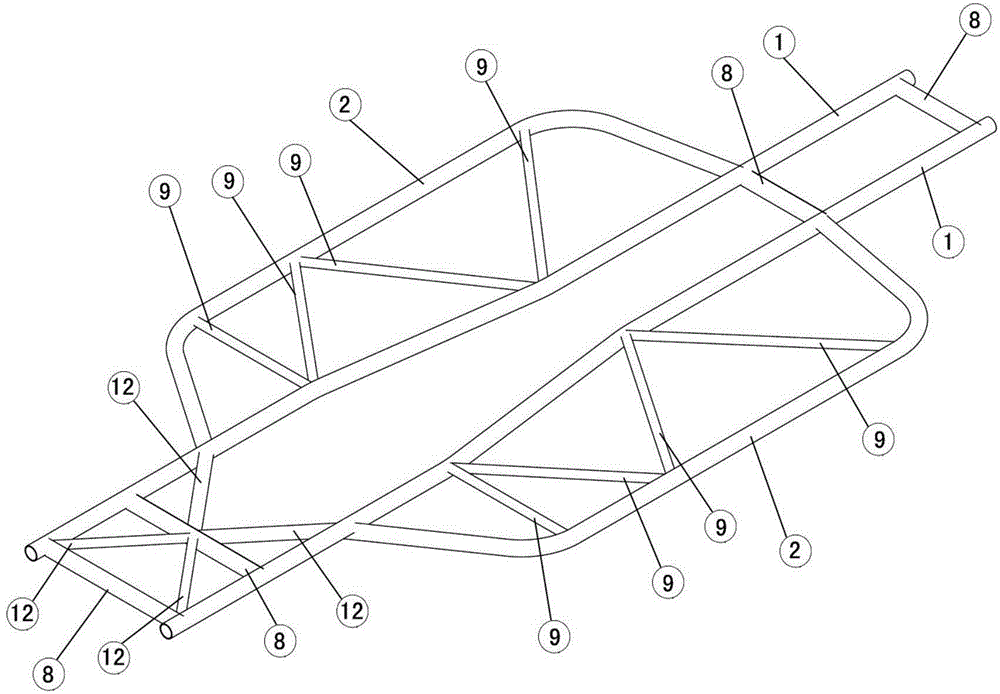

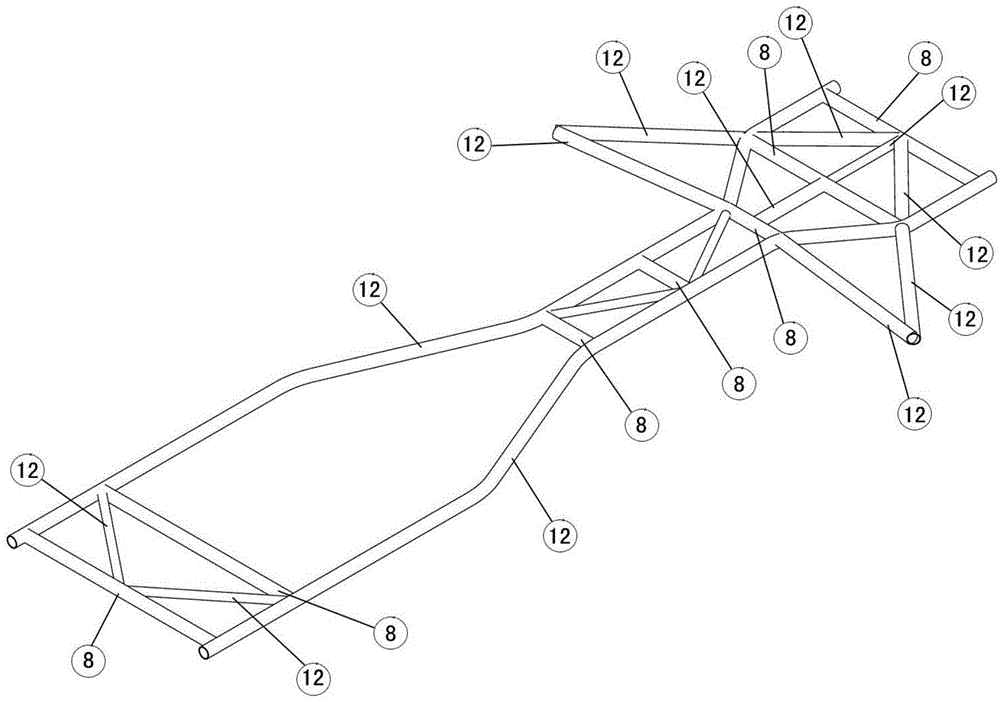

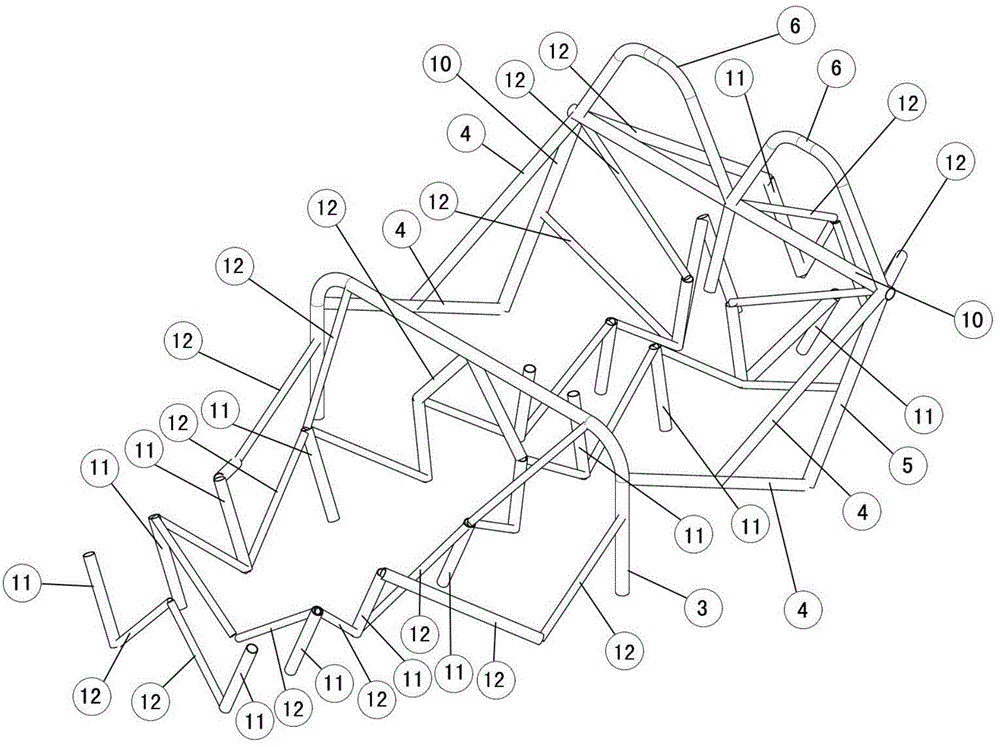

[0027] Such as Figure 1 to Figure 6 As shown, the automobile tubular frame of this embodiment includes a bottom tube frame 222 and an upper layer tube frame 111 located above the bottom layer tube frame 222, and a plurality of vehicle frame vertical beams 11 are fixed between the bottom layer tube frame 222 and the upper layer tube frame 111 connect. The bottom pipe frame 222 includes two first vehicle body longitudinal beams 1 and two passenger cabin longitudinal beams 2 arranged side by side; the two first vehicle body longitudinal beams 1 are fixedly connected to each other through a plurality of vehicle frame beams 8; The passenger compartment longitudinal beams 2 are arranged on both sides of the two first vehicle body longitudinal beams 1, and the two ends of the two passenger compartment longitudinal beams 2 are respectively bent towar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com