Scrubbing device of quartz ceramic roller in glass tempering furnace

A quartz ceramic and glass tempering technology, which is applied in glass tempering, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of low cleaning efficiency and long cooling time, and achieve the effect of reducing labor intensity and improving scrubbing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

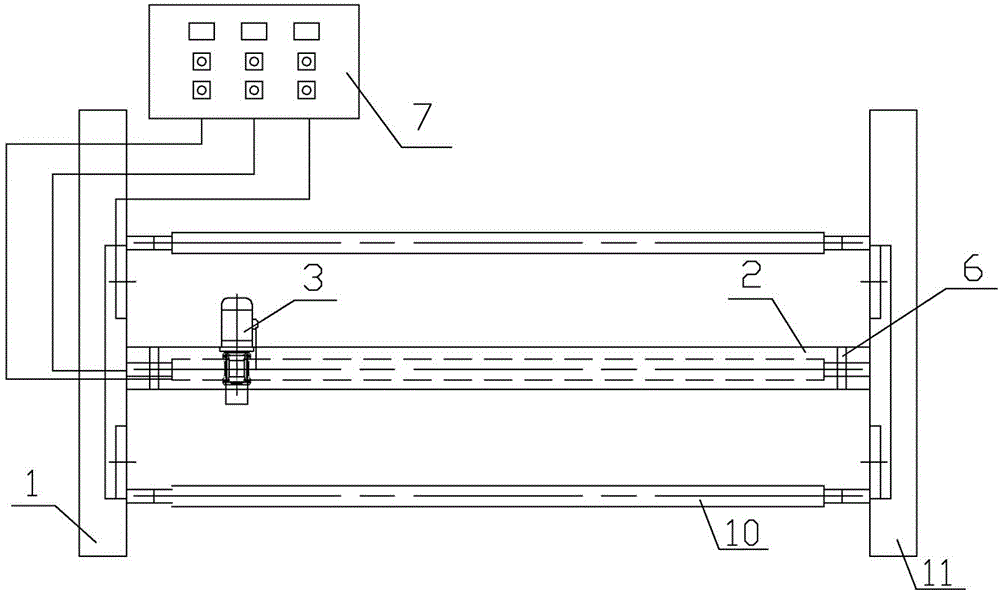

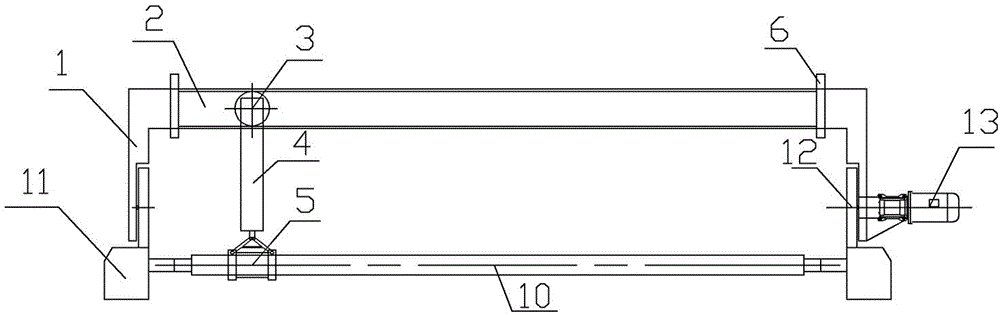

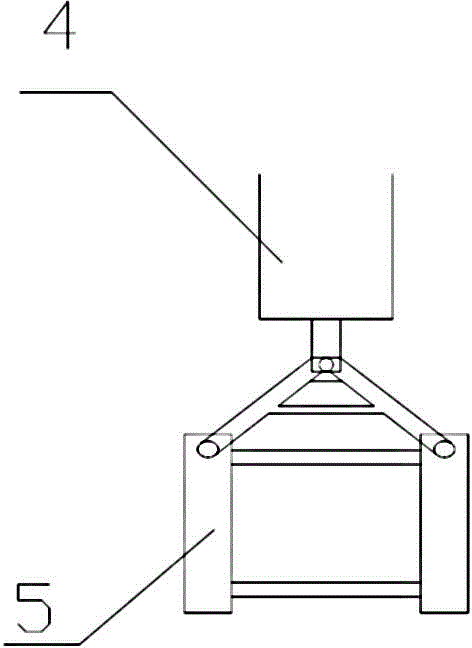

[0016] Such as figure 1 , figure 2 As shown, an automatic quartz ceramic roller table scrubbing device provided by the present invention includes a support frame 1 for supporting and moving back and forth along the tempering furnace. The support frame 1 is erected on the side table 11 of the tempering equipment. The end is equipped with a driving wheel 12, which is controlled by a driving motor 13, and the driving motor 13 is controlled by a PLC controller 7. Driven by the driving wheel 12, the support frame 1 moves back and forth along the glass running direction on the side table 11 to support The rack 1 is provided with a guide rail 2 parallel to the quartz ceramic roller 10, and an electric lifting rod 4 is slidably fitted on the guide rail 2. Both ends of the guide rail 2 are provided with baffles 6 which restrict the sliding of the electric lifting rod 4, and the electric lifting rod 4 is driven by Controlled by the motor 3, the bottom of the electric lifting rod 4 is equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com