Graphite reactor convenient to clean

A technology of reaction kettle and reaction kettle body, which is applied in the field of graphite reactor, can solve the problems of long time, unsatisfactory effect, corrosion of the bottom of the reactor, etc., and achieve the effect of prolonging the service life, fast and effective cleaning, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

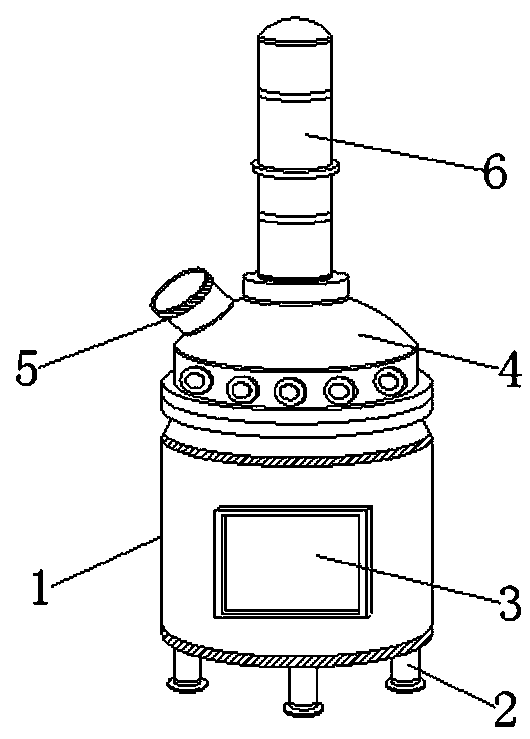

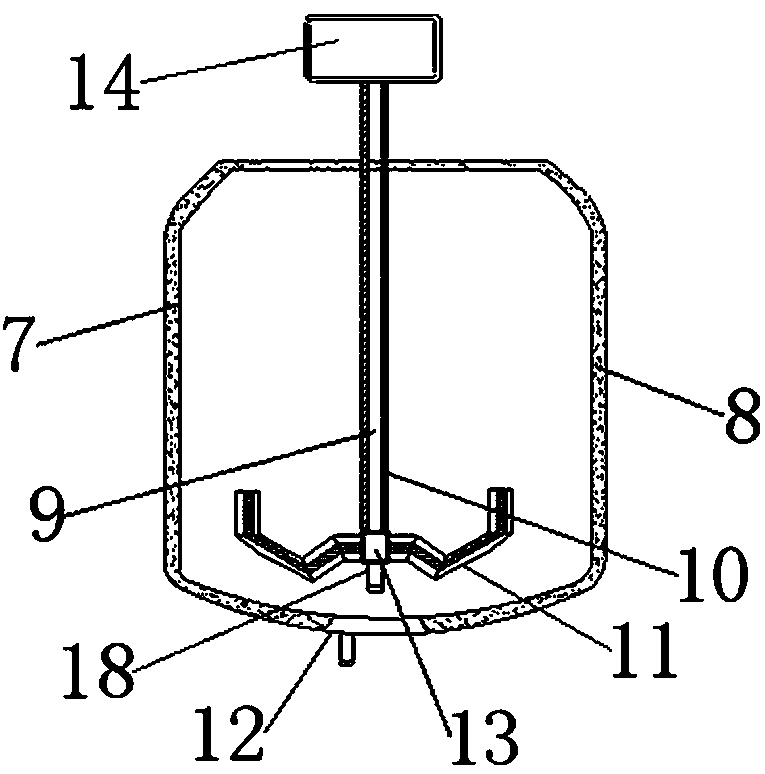

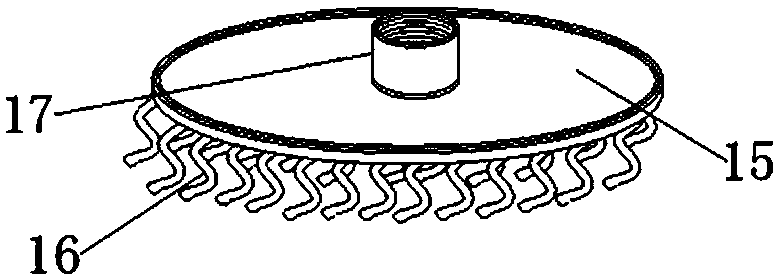

[0021] see Figure 1-3 , a graphite reactor that is easy to clean disclosed by the present invention comprises a reactor body 1, an upper cover body 4 and a pipe body 6, an upper cover body 4 is movably connected above the reactor body 1, and the upper cover body 4 is fixedly connected with a pipe body 6, the bottom of the reaction kettle body 1 is tightly welded with a foot 2, and an observation window 3 is installed in front of the reaction kettle body 1, and the upper cover 4 is located on the left side of the pipe body 6 A feed inlet 5 is fixedly connected, a motor Y250M2-4B35 type 14 is installed in the pipe body 6, and a vertical shaft 9 is fixedly connected below the motor Y250M2-4B35 type 14, and the reaction kettle body 1 is fixed inside Connected with an inner cavity 7, shafts 10 are provided on the left and right sides of the vertical shaft 9, and a slider 13 is slidably connected to the vertical shaft 9, and the slider 13 communicates with the motor Y250M2-4B35 typ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com