Excavation unloading device suitable for geomechanical model tests

A technology of geomechanics and model testing, applied in the direction of measuring devices, scientific instruments, instruments, etc., can solve the problem of difficult suction of granular materials, and achieve the effects of convenient control, good overload performance, and simple structure of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

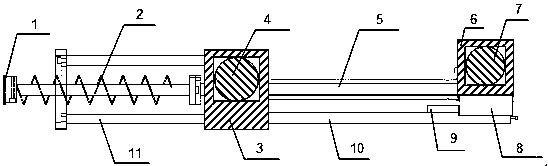

[0020] An excavation and unloading device suitable for geomechanical model tests, including a cutting drill bit 1, an auger rod 2, a propulsion reduction box 3, a first stepping motor 4, a lead screw 5, a rotating reduction box 6, and a second stepping Motor 7, slider 8, displacement sensor 9, linear guide rail 10 and fixed frame 11.

[0021] The input end of the propulsion reduction box 3 is connected with the output end of the first stepping motor 4, the input end of the rotation reduction box 6 is connected with the output end of the second stepping motor 7, and one end of the leading screw 5 is connected with the output end of the rotation reduction box 6 The other end passes through the output end of the propulsion reduction box 3 and is welded with the auger rod 2 (flange connection, bolt connection, etc. can also be used), and the other end of the auger rod 2 is welded with the cutting bit 1 (also can be connected by bolts) ). One end of the linear guide rail 10 is wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com