Cable connecting housing for ultrahigh-voltage GIS breaker switch

A circuit breaker switch, cable connection technology, applied in the direction of cable joints, cable accessories, cable installation, etc., can solve problems such as inconvenience to observe the operation status of internal structural parts, inconvenient installation of 3-phase cables, and inconvenient equipment installation/maintenance. , to avoid arcing discharge, improve sealing protection ability, and increase the effect of spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

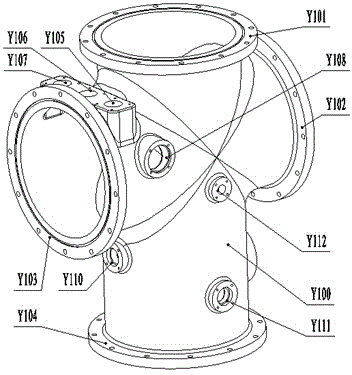

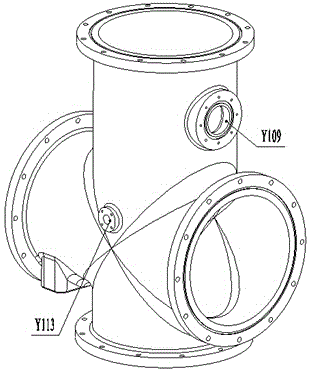

[0028] Such as Figure 4 As shown, the three-dimensional view of the cable connection housing DLK10 of the present invention, its external dimensions length × width × height = 900 mm × 710mm × 1150mm, the weight is about 200kg, the main structure includes connecting flange 1 FL11, connecting flange 2 FL12, connection method Lan 3 FL13, cable terminal connection flange 1 DFL21, cable terminal connection flange 2 DFL22, cable terminal connection flange 3 DFL23, cable built-in area DLK11, grounding switch 1 ES31, grounding switch 2 ES32, grounding switch 3 ES33, driving mechanism Installation structure 1 DA41, drive mechanism installation structure 2 DA42, manual connection flange 1 MFL51, manual connection flange 2 MFL52, manual connection flange 3 MFL53, manual connection flange 4 MFL54, inflation nozzle GC60, explosion-proof disk DEV71, observation window SF81 / ST82 / SE83 and DH91 / DH92 lifting holes.

[0029] Four symmetrical mounting angle structures and water / air double seali...

Embodiment 2

[0040] In the present invention, connecting flange one FL11, connecting flange two FL12, and connecting flange three FL13 add four symmetrical installation angles on the outside, so that the fixing of the end sealing cover plate and the connecting flange is more firm, and at the same time, the connecting flange adopts Sealing groove 1 (X101) and sealing groove 2 (X102) are provided, of which sealing groove 2 (X102) is a gas sealing groove to prevent internal SF6 gas leakage and ensure that the gas pressure meets the requirements of use; sealing groove 1 (X101) is a water sealing groove , prevent external water / water vapor from entering the equipment and cause failure, and can also be used as two air-tight tanks.

Embodiment 3

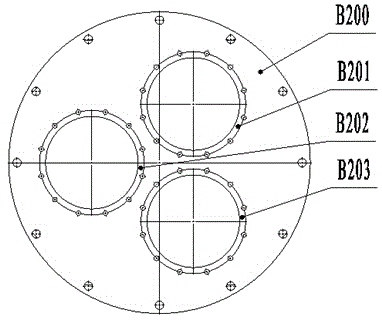

[0042] The cable terminal connecting flange 1 DFL21, the cable terminal connecting flange 2 DFL22 and the cable terminal connecting flange 3 DFL23 in the present invention are used to respectively install the terminals of 3 cables, which is different from the existing cable connecting shell, and the 3 cable terminal connecting method The blue structure is a separate cable installation seat plate structure, which is evenly and symmetrically distributed at the end of the main housing DLK10 at 3×120°. The three-phase cables can be directly installed and connected to the main housing without indirect installation through the intermediate flange. Equipment installation and maintenance are convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com