Optimal Design Method for High Speed Torque of Low Voltage AC Asynchronous Motor

An AC asynchronous motor, optimized design technology, applied to asynchronous induction motors, electromechanical devices, electrical components, etc., can solve the problems of poor high-frequency torque characteristics of low-voltage AC asynchronous motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

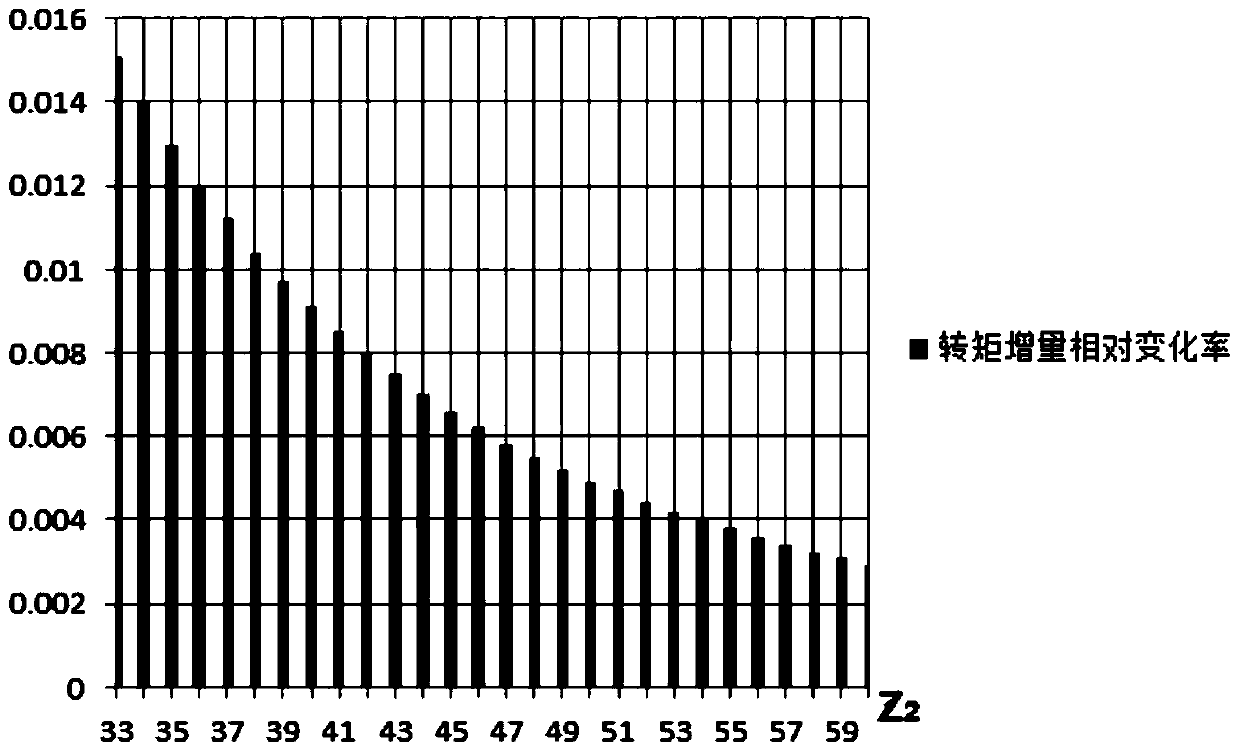

[0029] This embodiment optimizes the number of rotor slots of a low-voltage AC asynchronous motor with a rated power of 20Kw, a power supply DC voltage of 72V, a frequency of 0-300Hz, a number of pole pairs of 2, and a stator-rotor slot matching of 36 / 32. Since the driving object requires that the highest possible electromagnetic torque output can be obtained at high speed at a certain cost, it is considered to keep the stator and main dimensions of the motor unchanged, and optimize the design of the motor by increasing the number of rotor slots. The specific steps are as follows :

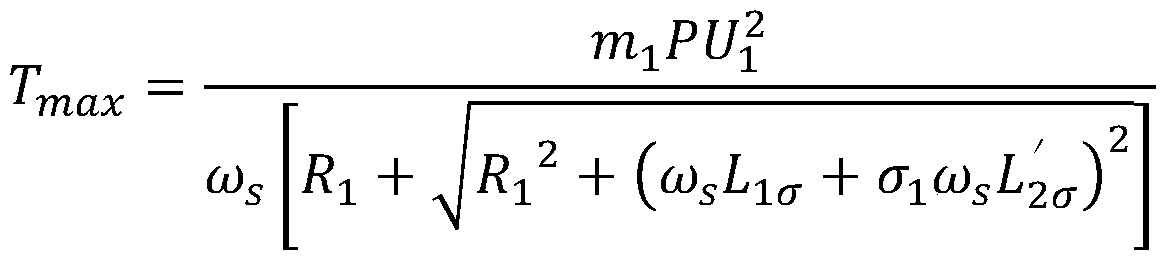

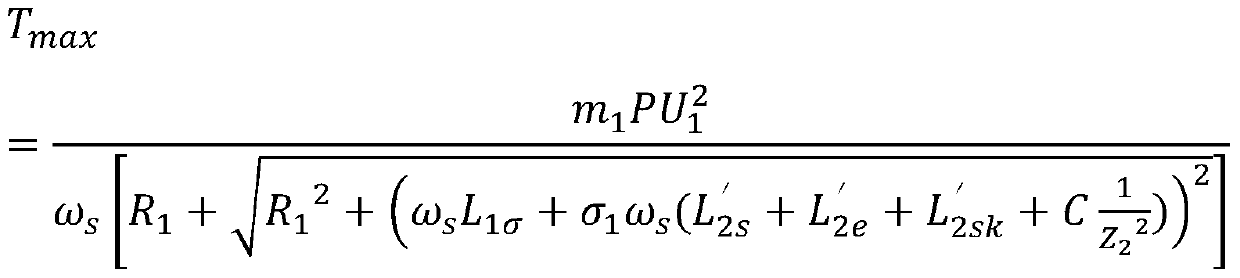

[0030] 1) First establish the motor model in the ansoft software, and obtain the parameters of the low-voltage AC asynchronous motor to be optimized: the stator winding resistance R 1 , the rotor winding converted resistance R 2 , the supply angular frequency ω on the stator side s , stator leakage reactance L 1σ , rotor slot converted leakage inductance L′ 2s , the converted leakage inductanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com