Sensor and method for manufacturing a sensor

一种传感器、衬底的技术,应用在传感器领域,达到简化制造的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In the different figures, identical components are always provided with the same reference symbols and are therefore generally also described or illustrated only once in each case.

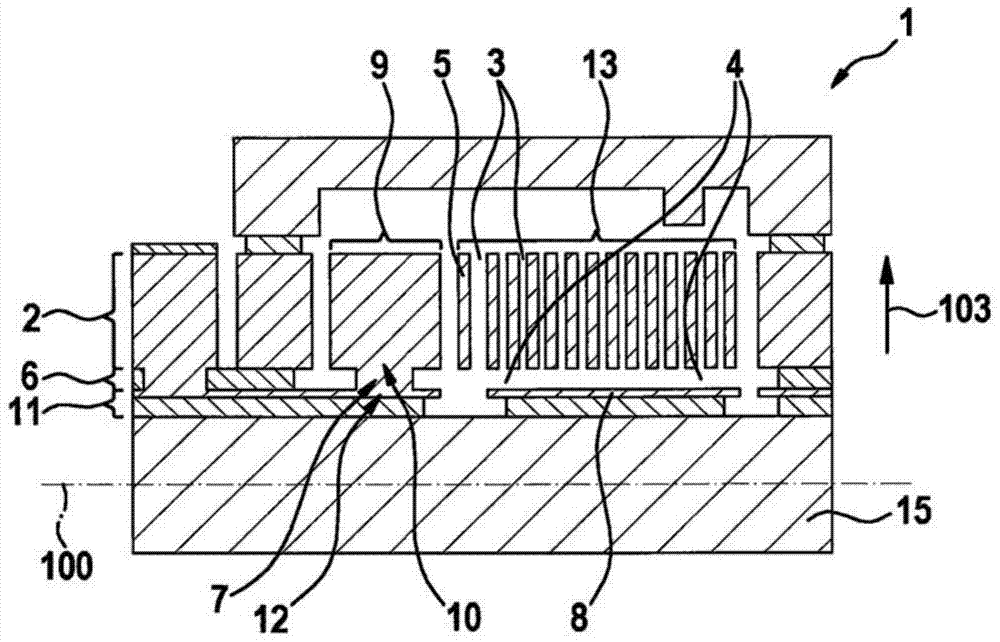

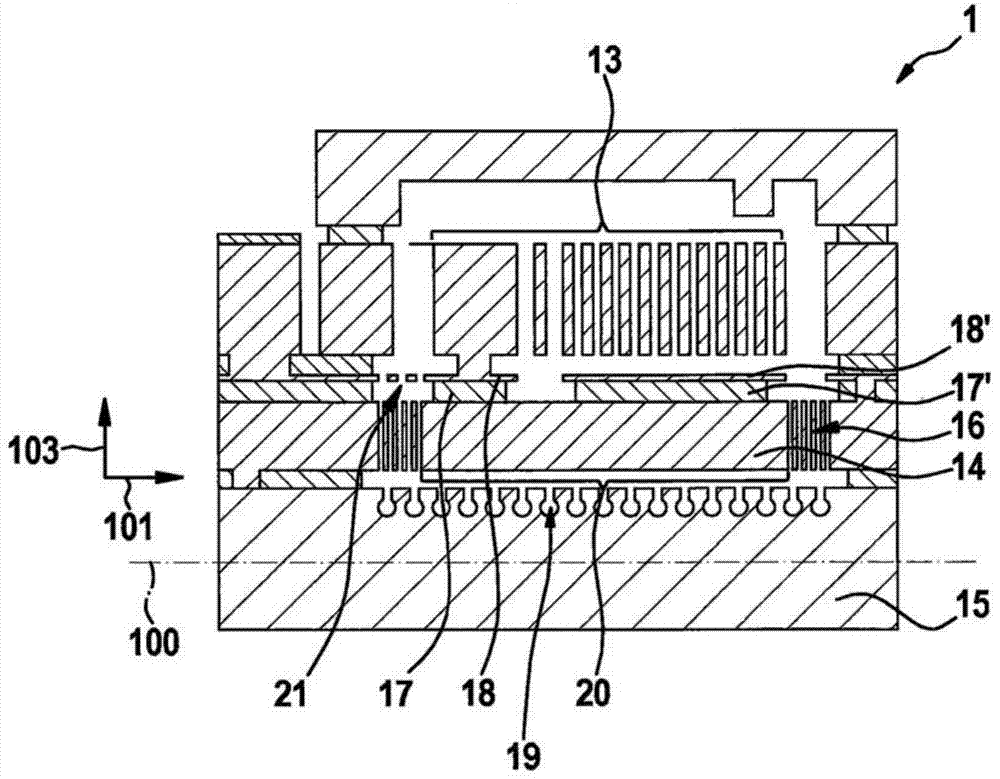

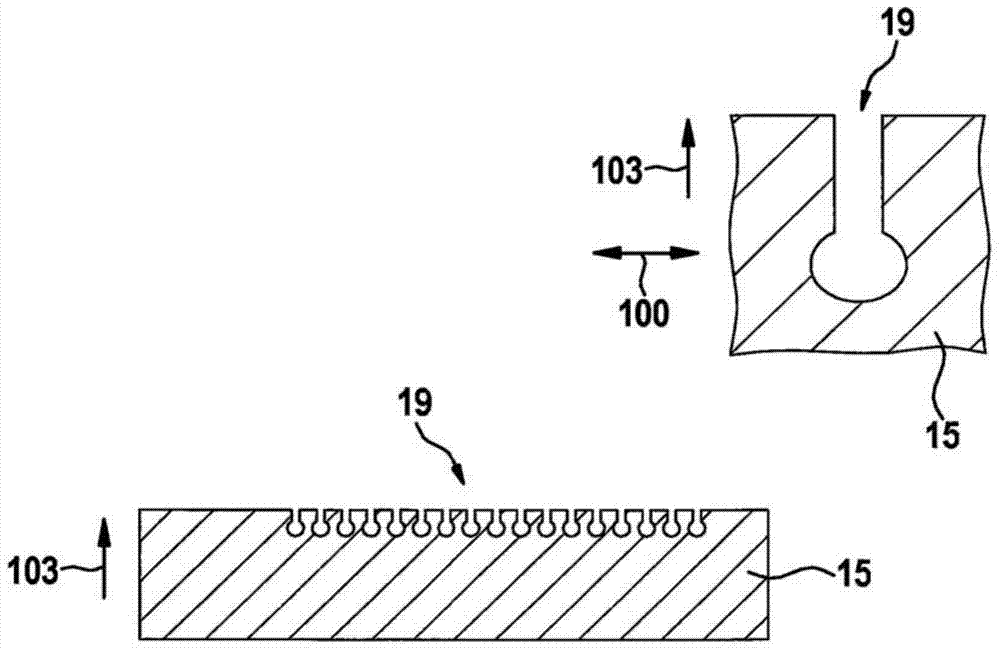

[0037] exist figure 1 A sensor 1 according to an embodiment of the invention, in particular an acceleration sensor and / or a rotational speed sensor, is shown in a sectional view, wherein the basic structure of the sensor 1 is mainly described here. Here, the basic structure comprises a microelectromechanical element (MEMS element) 1' movable relative to the substrate 15 of the sensor 1 and a fixed structure 9 to which the MEMS element 1' is spring-elastically coupled. An offset or offset movement of the movable element 1' can be detected by the sensor 1 as a function of the capacitance change.

[0038] A movable MEMS element 1' is produced by means of an etching method from a (relatively thick) epitaxially (on the substrate 15 of the sensor 1 ) deposited polysilicon layer 2 (epitaxial pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com