Protective rod, rod for concrete structure, manufacturing process of rod body and anchor rod

A concrete structure and rod body technology, which is applied in basic structure engineering, bolt installation, earthwork drilling, etc., can solve the problems of easy leakage of anti-corrosion materials, easy doping with other sundries, and difficulty in achieving anti-corrosion effect, and achieve high use value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

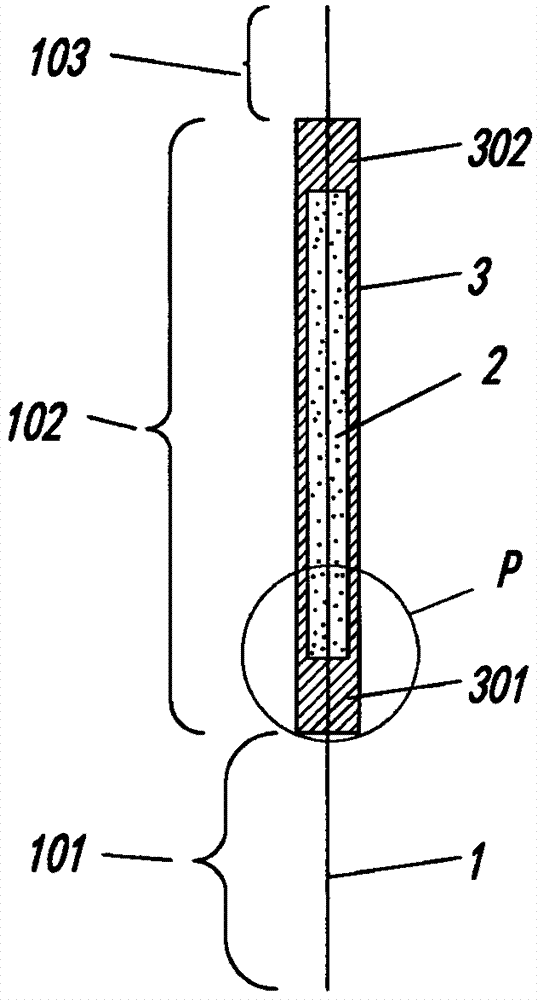

[0072] see Figure 5 , the anchor rod provided in this embodiment has the above-mentioned protective rod body, including a rod body 1, the middle section of the rod body 1 is a protection section 102, and the protection section 102 rod body is coated with a protective material 2, and the protection section 102 is also covered with a The protective cover 3 covered by the protective material 2, the lower end of the protective cover 3 also has a lower sealing fixed end 301 that can make the lower end of the protective cover 3 and the rod body 1 combined and fixed, so as to prevent the protective cover 3 from slipping and prevent the protective material 2 from leaking . The non-protective section on the upper section of the rod body 1 has a detachable protective section 104 , and the detachable protective section 104 has an isolation layer 10 .

[0073] In this embodiment, during on-site construction, the protective rod body can be placed in the anchor hole, and the cement slurry...

Embodiment 2

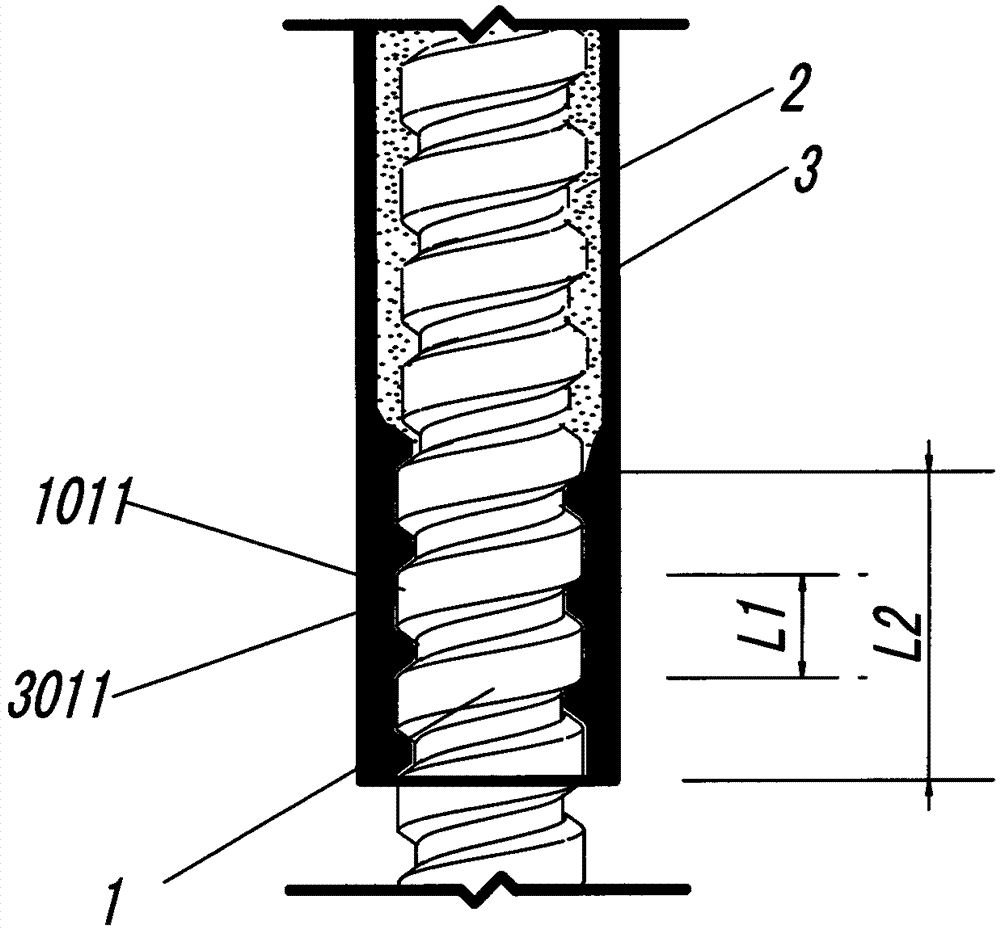

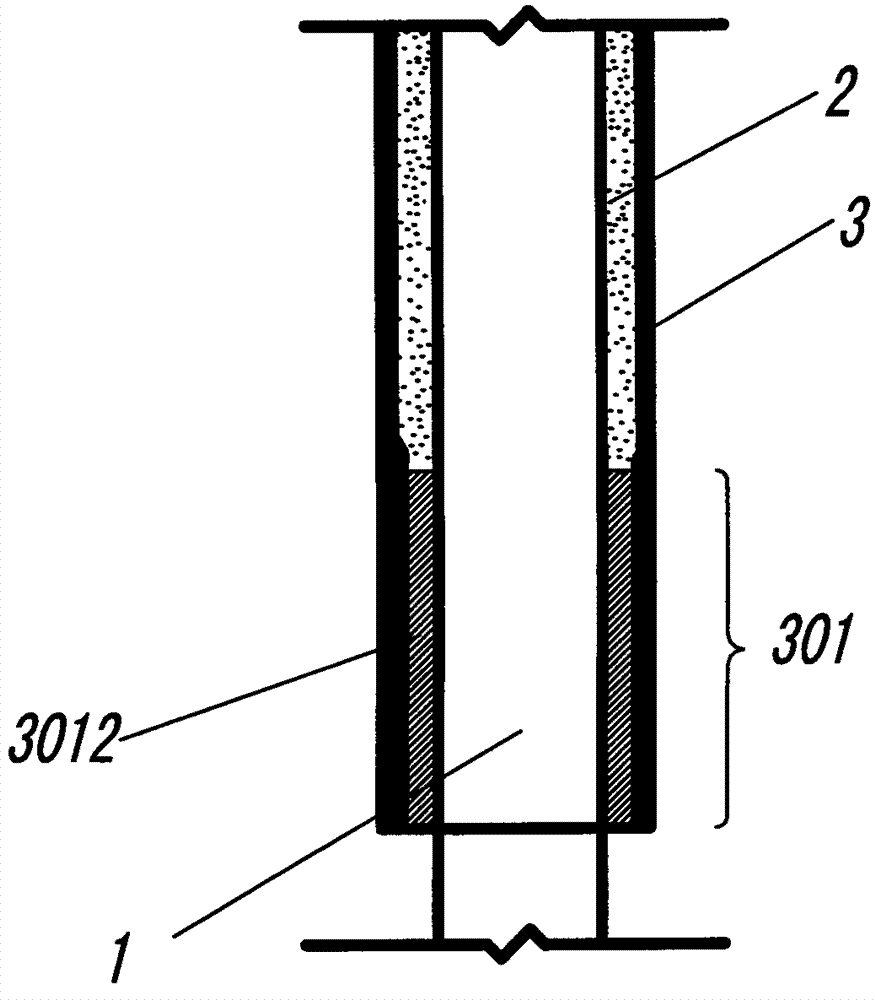

[0075] see Image 6 The structure of the protective rod body in this embodiment is the same as that of the first embodiment of the anchor rod. The component can transmit force between the rod body 1 and the concrete, and between the rod body 1 and the cement slurry solidified body. The bearing body generally has a force-bearing surface in contact with concrete or cement slurry solidification, and the bearing body and the rod body 1 can be screwed, ferruled or welded; A support rod, the skeleton 42 and the grouting body 41 are integrated with the rod body 1 through the cast-in-place method. Since the lower section 101 of the rod body 1 is surrounded by a skeleton structure with the rod body as the center, the anchor rod can always be in the middle of the anchor hole during grouting construction, avoiding the deviation of the rod body 1 when it is placed in the anchor hole. The combined setting of the grout 41 greatly enhances the mechanical strength of the grouting body, impr...

Embodiment 3

[0077] see Figure 7 , the structure of this embodiment is basically the same as that of the second embodiment of the anchor rod. The difference is that the skeleton 42 of the lower section 101 of the rod body 1 is a spring or steel wire mesh sheathed on the lower section 101. The skeleton of this structure can increase the gripping force between the grouting body 41 and the rod body 1 and improve the anchorage. Rod resistance.

[0078] It can be understood that the frame 42 can also be a combination of a plurality of outwardly radiating support rods arranged on the lower section 101 of the rod body and the above-mentioned spring or steel mesh.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com