A kind of filling method of low temperature heat pipe

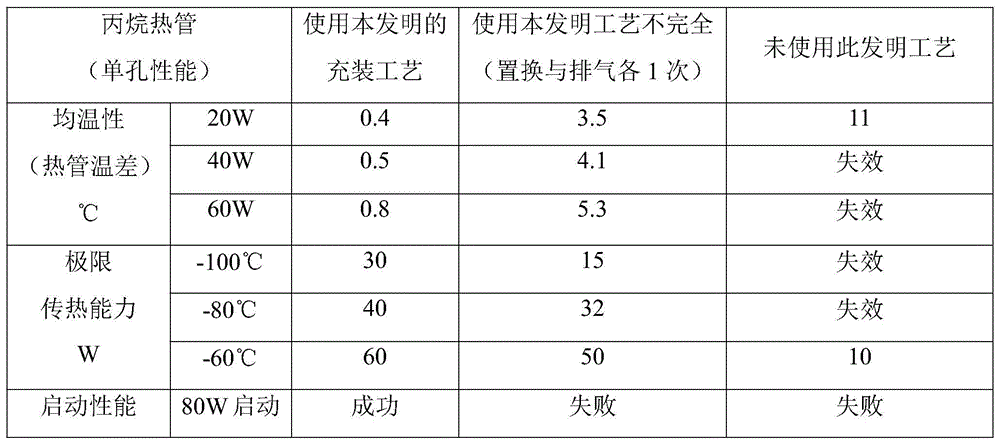

A technology of heat pipe and low temperature, which is applied in the field of spacecraft thermal control, can solve the problems of not being able to guarantee the filling purity of low-temperature working fluid, occupying the space in the low-temperature heat pipe tube, and attenuating the performance of low-temperature heat pipe, so as to solve the problem of filling purity and increase the limit Heat transfer capability, smooth start-up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Install the heat pipe to be filled on the filling equipment, and the inner diameter of the filling hole of the heat pipe to be filled shall not be less than 3mm;

[0027] (2) Turn on the vacuum pump of the equipment, evacuate the heat pipe to be filled until the vacuum degree reaches the order of 10Pa, close the vacuum valve of the heat pipe, open the filling valve, fill in 3-5g of propane working fluid and let it stand for 3 minutes;

[0028] (3) Open the vacuum valve of the heat pipe, directly extract the filled propane working medium, and continue to vacuumize to the order of 10Pa, and then repeat steps (2) and (3);

[0029] (4) After repeating 3 times, fill in the theoretical filling amount M+5g of low-temperature working fluid, then cold weld and seal, and use a 40°C warm water bath to soak for leak detection;

[0030] (5) Submerge the heat pipe that has been replaced and filled vertically in a warm water bath with a depth of 300 mm and a depth of 40 ° C. After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com