Integrated double-sided air-cooled radiator and simplified power module

A technology of power modules and heat sinks, applied in cooling/ventilation/heating transformation, modification of power electronics, electrical components, etc., can solve the problem of taking up a lot of time cost, procurement cost, large inventory pressure, and the inability to guarantee the isothermal performance of parallel IGBTs To achieve the effect of improving product performance and system reliability, reducing procurement costs and inventory pressure, and reducing long-term procurement risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The scheme of the invention includes two parts, one is an integrated double-sided phase change heat pipe radiator, and the other is a simplified power module.

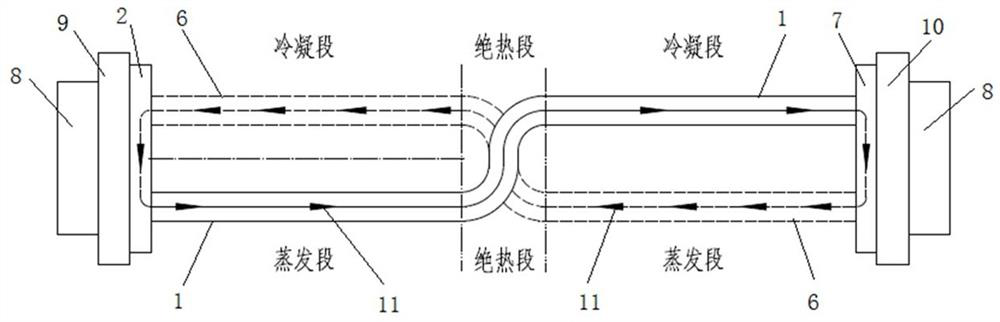

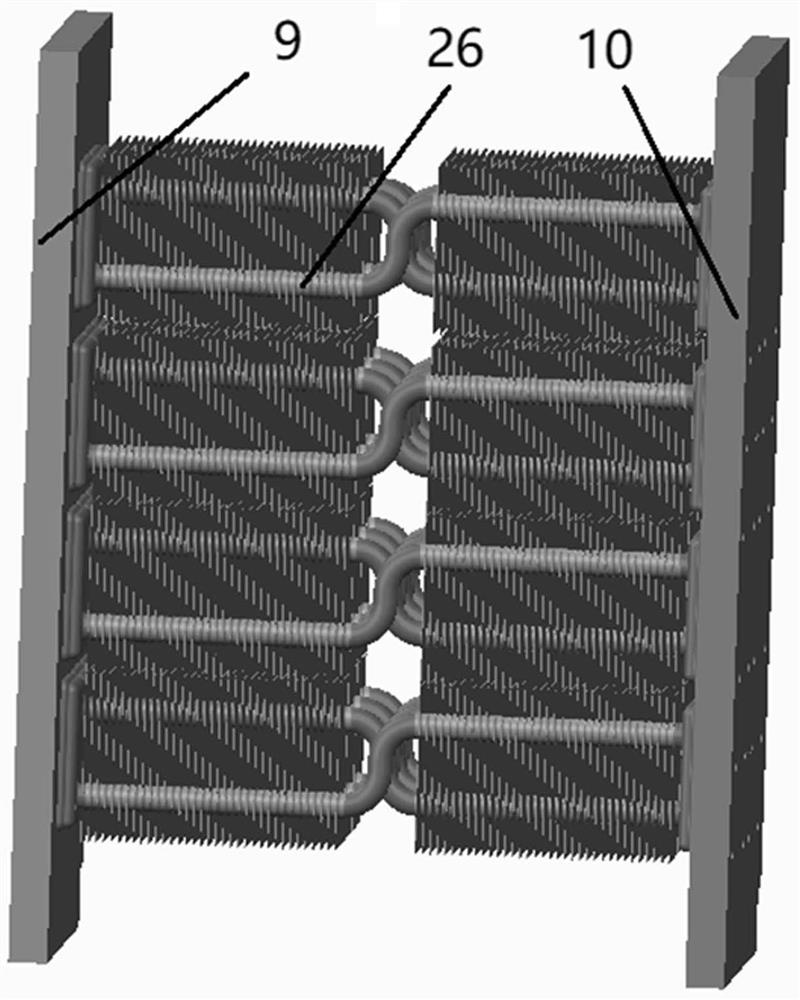

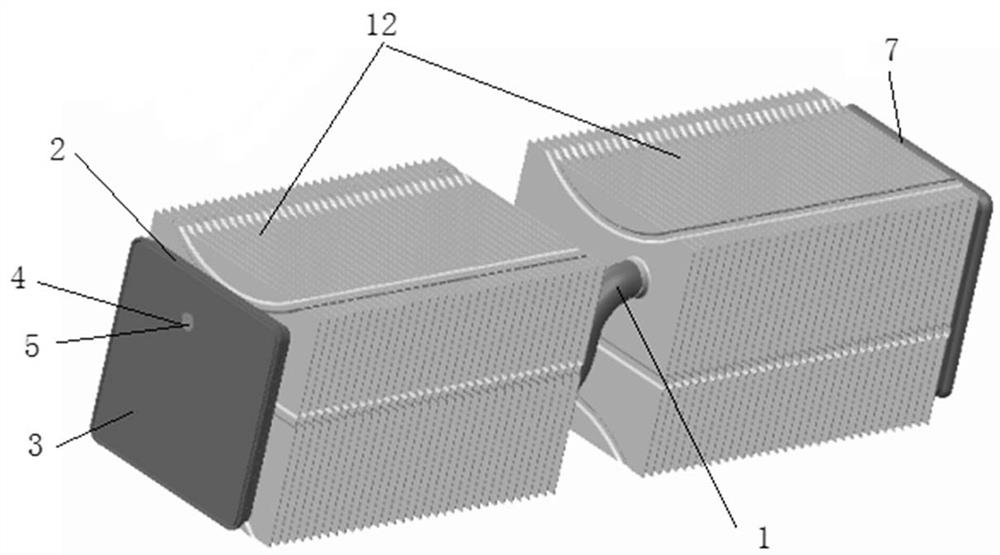

[0040] 1) Integrated double-sided phase change heat pipe radiator solution

[0041] The integrated double-sided phase change heat pipe radiator includes two heat dissipation substrates and a heat pipe radiator assembly. The heat pipe radiator assembly includes a liquid storage box, a primary heat dissipation structure (phase change heat pipe) and a secondary heat dissipation structure (radiation fin). Its heat transfer efficiency is high, and the temperature distribution on the surface of the heat dissipation substrate is more uniform. Its working principle is as follows: figure 1 shown. The power device 8 is installed on the heat dissipation substrate. When the power device 8 on the substrate is in operation, the first heat dissipation substrate 9 is heated to generate a hot spot 1, and the second heat dissip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com