Combined template detection system and method

A technology of combining templates and detection systems, applied in the field of shape recognition, can solve the problems of low efficiency and low accuracy, and achieve the effect of improving measurement efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

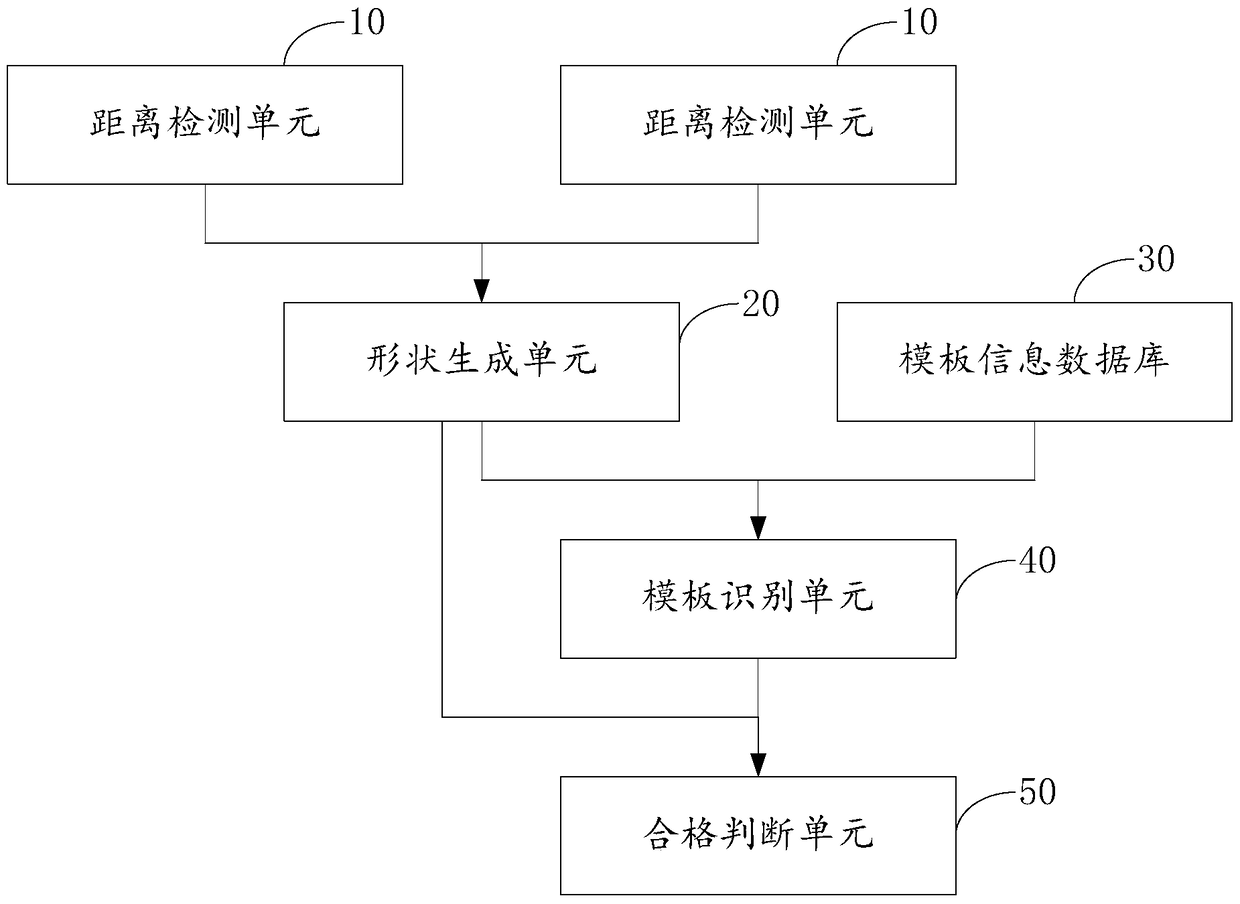

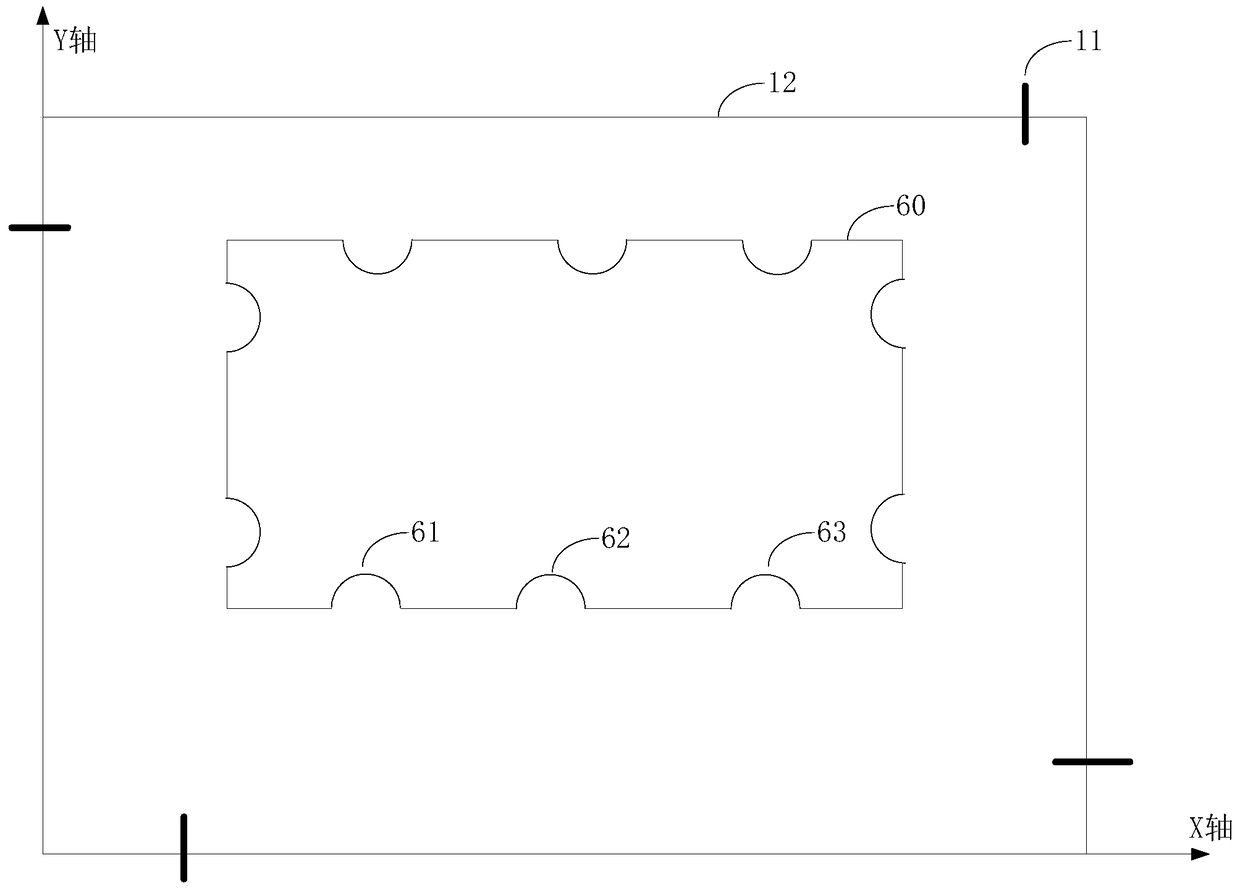

[0047] see figure 1 , figure 2 , Figure 6 , the present invention discloses a combined template detection system, which includes: four distance detection units 10 , a shape generation unit 20 , a template information database 30 , a template recognition unit 40 , and a qualification judgment unit 50 .

[0048]Four distance detection units 10 surround a rectangle (other numbers of distance detection units can also surround a rectangle or a polygon), which can surround the composite template 60 in the middle; four distance detection units 10 detect four composite templates 60 respectively The distance between each point on the azimuth and the corresponding point on the distance detection unit 10 , and send the distance information to the shape generation unit 20 .

[0049] Each distance detection unit 10 comprises a horizontally arranged slide rail 12, a distance detector 11 that can slide on the slide rail 12, and controls the distance detector 11 to move at a uniform speed...

Embodiment 2

[0062] The invention discloses a combined template detection system, which includes: a distance detection unit and a shape generation unit. The distance detection unit is used to detect the distance from each point on the periphery of the combined template to the distance detection unit; the shape generation unit is used to generate the shape of the periphery of the combined template according to the distance information detected by the distance detection unit.

[0063] The present invention also discloses a combined template detection method, which includes the following steps: the distance detection unit detects the distance from each point on the periphery of the combined template to the distance detection unit; shape.

[0064] In addition, the above method may also include the following steps:

[0065] The template recognition unit compares the generated template data with the template data stored in the template information database, and if the comparison error is within...

Embodiment 3

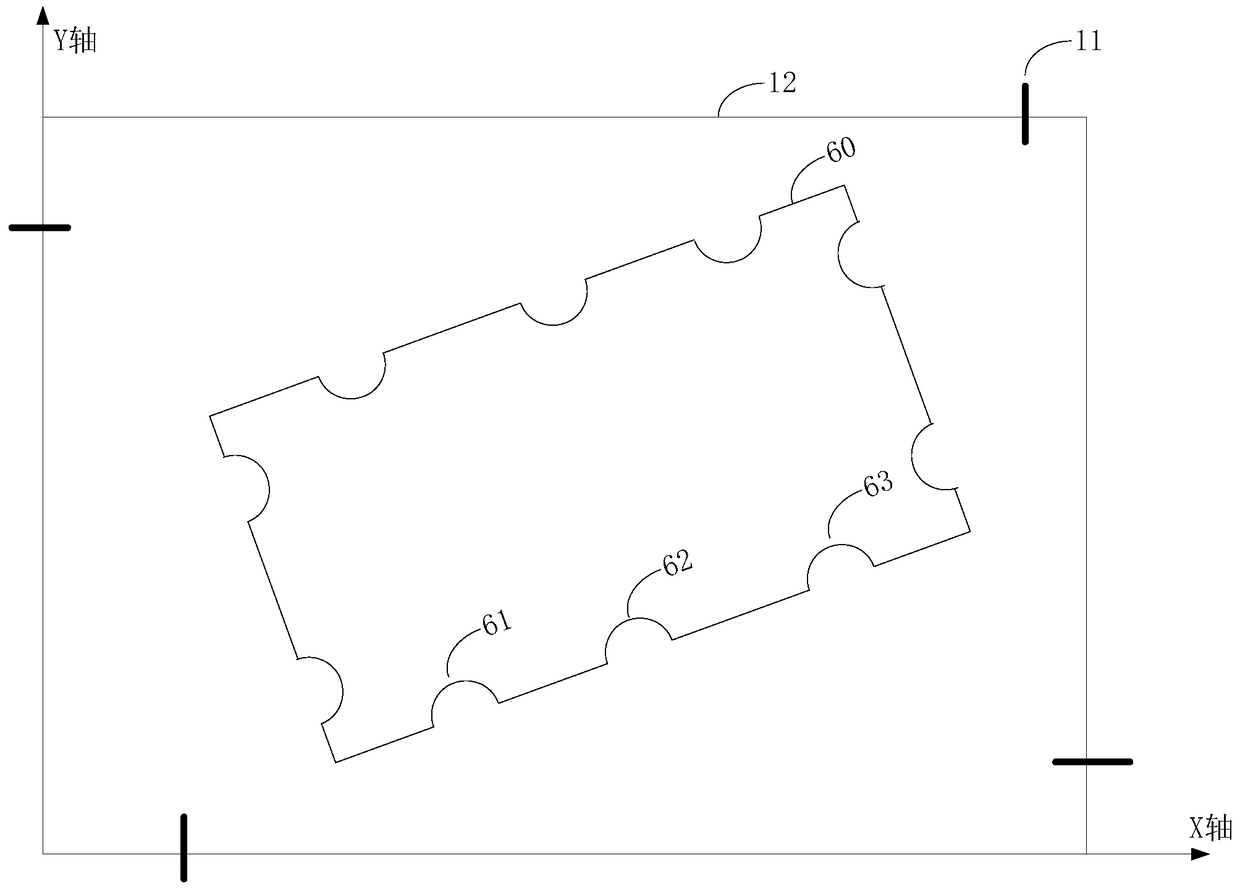

[0068] The difference between this embodiment and Embodiment 1 and Embodiment 2 is that in this embodiment, part or all of the distance detection units 10 may not be arranged parallel to the detection sides of the corresponding combination template, and corresponding shape information may still be generated according to the distance information. Such as image 3 shown. In addition, the number of distance detection units can be other numbers, such as 3, 5, or 6. There can also be 5 or 6 sides of the combination template (such as Figure 6 Shown) or other quantities, the sides of the combination formwork can also be curved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com